Customer Story: Meridian & Genesis Energy

How to optimize 3D Scan Data for Digital Twin

Leading Energy companies optimize their 3D Digital Scans for Digital Twin applications

“With Cintoo lots of experts and non-experts in the office are virtually browsing the power stations and taking measurements from their monitors. All are getting value from the 3D Digital Twin scans long after the initial purpose of capturing was met.“

Yanosh Irani,

Meridian Energy Ltd

Background

Many asset owners have been capturing 3D scan data for over a decade to assist with specific cases of design, construction, maintenance or operations for AEC BIM or Digital Twin applications. However, after that initial purpose was met, data was usually lost or inaccessible with high storage costs. This use case is about how Meridian Energy and Genesis Energy independently arrived at using the same cloud-based platform from Cintoo to store their 3D scan data, the technical and organizational challenges they had to overcome, and some thoughts on the future of this technology for Digital Twin and AEC BIM.

The various options and challenges with data capture are presented. This includes terrestrial laser scanning, panoramic photography and 3D photogrammetry.

Practical examples are presented of how 3D scan data was used long after the original capture to:

- Provide better context and data connectivity for assets and equipment for Digital Twin

- Support better decisions by maximizing insight and understanding of asset condition

- Improve project engagement, planning and communication

- Save project cost while reducing risk

Examples are given where different types of data were integrated into the same platform. Considerations about the long-term management of this data are discussed including cost effective options to keep it up to date. Both asset owners have only just started scratching the surface of what is possible. The paper finishes with a discussion about future avenues the platform and this technology could take and provides some guidance for any other asset owners looking to travel down the same road.

Solutions for modern asset information management can include a combination of Engineering Document Management Systems (EDMS), technical drawings, asset registers, 3D point cloud management, digital twins, 3D model management and Building Information Modelling (BIM) to name a few. An asset owner must sift through a myriad of products, vendors, consultants, jargon and frameworks to find clarity before determining what meets their business needs within their operating constraints.

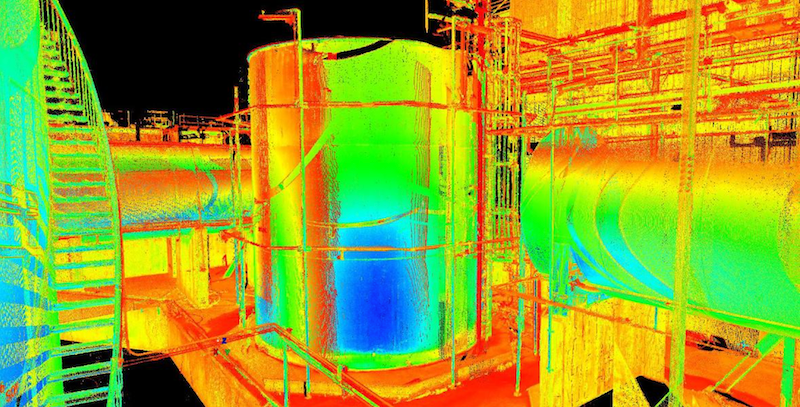

This paper is about the experience of Genesis Energy and Meridian Energy taking advantage of modern sources of asset data for Digital Twin – specifically 3D point cloud data as shown below. The data is usually captured by 3D laser scanners or photogrammetry which is explained in this article.

The Situation

3D Point cloud data has been collected for assets in New Zealand’s power industry for over a decade. Some previous examples of use cases include:

- Design of firewalls around transformers at hydro stations

- Asbestos identification at Huntly station

- Fire compliance review for Genesis hydro sites

- Assessment of 220 kV clearances at all Meridian connected switchyards

Example of technical drawings augmented with 3D Point cloud data

Workflows Used

Laser scanner: Terrestrial, Handheld & Drone

Cintoo Cloud

Point cloud software: Faro Webshare

Modeling software: Autodesk ReCap

The data was collected using terrestrial laser scanners operated by consultants. The final outputs were technical drawings augmented with a snapshot of the point cloud data.

In some cases, the point cloud was stored and viewed through desktop software like Autodesk ReCap®. This had limited success due to limited licenses in a large organization, huge file-sizes and associated storage costs for network drives. A common workaround was to store the data on portable hard drives and USB thumb drives which made sharing impractical and was not the best outcome from a data security point of view.

In other cases, the data was presented to the asset owner in cloud-based viewers, but these had limited success. This was generally due to the use of proprietary file types which limited the sharing, export and manipulation of the data. In some cases, the data was never requested by the asset owner and was left with the design consultant or scanning subcontractor.

Methodology Solutions

Genesis Energy and Meridian Energy independently investigated solutions and methods for capturing 3D scan data, storing it, managing it and sharing it.

Reality capture options

There are multiple reality scanning solutions available depending on the level of accuracy and detail required, the scale of the scanning and the available time.

- 360 panoramic imagery: Can be taken with relatively cheap commercially available solutions. Often taken automatically by terrestrial laser scanners. Fast data capture. Some platforms offer low accuracy measurement. Can be combined with laser scans in most platforms. On its own, doesn’t provide the same price performance as laser scanning once site visits are considered.

- Laser scanning:

Terrestrial laser scanners – Reasonably high accuracy and suitable for large and small jobs. 2-3 mm Accuracy, 5-10 mins per scan.

Portable mobile mapping – Numerous solutions are available including helmet/backpack mounted versions enabling quick low-quality capture of large areas.

High accuracy handheld – For detailed high accuracy needs. 03-0.05 mm Accuracy. Indoors only with clean surfaces and lots of target stickers required as shown below.

Drone/Robotic – Suitable for large sites or special applications

- Photogrammetry: 3D data extracted from high resolution Accuracy depends on measured control/survey points. Can be done via drone or portable camera. Can combine with point cloud data to improve results

Meridian and Genesis choose to go with a combination of terrestrial laser scanning and augment this with 360 panoramic imagery where feasible or efficient to collect more granular data.

High Accuracy Handheld Scanning

Data Processing Importance

The most important and often underestimated part of creating digitally navigable 3D point clouds is registration. Registration is the process by which individual scans are linked together using special software in the same co-ordinate system with associated data like panoramic images and depth maps to produce what is called a structured scan.

Depending on the reality capture method, there can be a trade-off between time spent on site and time spent processing. More time on site placing reference targets can speed up the processing back in the office and vis versa where a fast capture method can result in lengthy off-site processing. Both asset owners chose methods based on the respective costs of time spent on site and time spent post processing.

It can be tempting to avoid processing to save time and cost by storing unstructured scan data once the specific project purpose has been met. However, this is a false economy as the structure of the scan can get lost and it can be impossible to upload and navigate in future platforms. It is highly recommended that all 3D scans are registered to create structured scans to leave the most future possibilities open for storing, manipulating and using the scan data.

The registration process of 3D scans

The Data Platform is Essential

The right platform for storing 3D point cloud data for Digital Twins and AEC BIM applications is a critical factor which determines if the data adds value to the asset owner or gets neglected after a single use.

Important factors to consider in a platform include:

Proprietary vs Open: Ensure you don’t get locked into a single system and the data can be freely moved to another platform in the future.

Cloud storage: Essential for large file sizes in the order of terabytes – neither Genesis nor Meridian have found on-premise storage to be viable for 3D data from a cost, security or user experience ROI.

Cost structure: Platforms and solutions on a per user, per-scan were found to limit the scaling and usage of the platform. Licensing with unlimited users was found to be critical to the uptake and subsequent value generated by the platform.

Sharing and collaboration: To assure usage and adoption as well as security, management of sharing and permissions and remote access for multiple users is imperative.

IT and data security: Single sign on with integrated IT security is a must.

Export of data: Ability for some users to export data to assist with design was found to be essential.

Integrations with other tools and platforms: Either inherently or via API’s such as drawing management systems and BIM platforms is typically required.

User experience: Intuitive platforms with thorough user documentation is important to reduce the amount of training required and assure user engagement by non-technical as well as technical users.

Functionality: Having all file types accepted, including 360 images, along with asset labelling is essential.

After independently reviewing several options, both asset owners independently selected Cintoo Cloud® as the optimal platform. With per scan licensing and a good user experience Cintoo Cloud met all the requirements along with some additional features.

Cintoo Cloud Dashboard

Implementation and Use Cases

For both Meridian and Genesis, implementation of the Cintoo platform was completed by a local Cintoo reseller and 3D scanning service provider, Revisia Ltd. Some interesting challenges during the process included:

- Coordinate systems: The decision was whether to implement a Relative coordinate system or georeferenced with survey control. For one site Meridian had existing geo-referenced scans to link the new scans On balance this decision had more downsides than benefits as any new models, photos or artefacts had to be pre-configured with co-ordinates or the default origin (0,0,0) would stretch the boundaries of the scan and crash the system. Future 3D scans were added with relative co-ordinates to a fixed reference point with no survey control.

- Processing and uploading of historical scan data: The success of the Cintoo platform had both asset owners scrambling to find old point cloud data sitting on hard drives and file servers in the possession of consultants and contractors. Whilst most of the data was found in the appropriate format to upload to Cintoo, some of the data was not registered or processed. Some of the past data was lost by design consultants due to changing staff and data migration. This highlighted why it is important to clearly define in advance what deliverables are expected from service providers. As a result, Meridian developed a 3D scanning specification to help clarify future requirements.

- Cultural change: There was considerable internal skepticism on the benefits of this investment in utilizing point cloud files. This is starting to change with people reaching for 3D data to answer questions before picking up the phone, sending an email or scheduling a site visit. The data is now viewed as an asset that continues to add value.

Photo taken on site and example of contextual information from scans

Scoping, Concept design and tendering use case

In the one year since implementation, Meridian has leveraged 3D scan data to complete a handful of concept designs and tenders for equipment supply or construction services without a site visit for the design consultant or manufacturer.

- Switchyard 220 kV CT replacements – Concept design, clearance assessments and tender all performed remotely

- Local service transformer replacements – Concept design, options assessment, site works and tender all completed remotely

- Various works involving quantity estimation of scaffolding, cable and pipe before travelling to site

Faster Digital Twin design iterations use case

Remote design teams often find themselves needing to check clashes, fit and contextual information on site during the design. Typical examples include how big is that floor penetration or will this panel fit?

Orthographic measurements to check fit and an example of equipment installed on site

These sorts of technical queries lead to delays, increased demand on site teams to investigate or additional site visits to resolve. It was found that having the 3D scan data substantially reduced the time, cost, resource and carbon emissions required to address technical design queries as designers could check and measure things for themselves.

The data also enabled design risk reductions. Units on generation sites are identical in theory but not always in practice as shown in below, leading to unexpected last-minute changes to design. On multiple occasions the 3D scans have enabled engineers to identify differences between units preventing mistakes.

A major automation upgrade project at Manapouri hydro station conducted a full 3D scan of the site including the infrastructure located 200 meters underground. In one year, the investment in the data has generated a positive return on the original investment through faster resolution of technical queries, less site visits, reduced risk of design clashes. This process has also provided similar benefits for a number of subsequent projects including fire protection works, emergency lighting upgrades and transformer replacements.

Differences shown of identical units that were installed differently on the same site

Project progression in a COVID environment use case

Meridian implemented the Cintoo platform and uploaded all new and historic scan data before some of the Covid-19 lockdowns. The data and platform became more valuable in an environment with restricted travel between generation sites. Projects in the conceptual and design phase were thrown a lifeline as they could continue progressing despite restrictions on site visits.

Genesis was able to progress a project at Tuai power station during a Covid-19 lockdown period in late 2019. The project was designed, coordinated and constructed whilst contractors and design consultants were restricted from visiting the site in order to validate measurements. The use of the 3D scan data helped the design consultant understand the areas of interest and also avoid resolved clashes while validating onsite boundary limits by the Genesis Energy staff. This led to successful creation of construction drawings as shown without a site visit by the design consultant.

Construction drawings created with 3D scan data and site works

Hazard identification use case

One of the first large scale uses of 3D point cloud data at Genesis was creating a virtual register of known/suspected asbestos hazards at the Huntly power station. The initial success of this work was limited by the Faro webshare® platform hosting this data due to its inherent licensing restrictions, lack of stability and the requirement for proprietary file types. The new Cintoo platform had none of these constraints and the asbestos hazards will be visible to anyone using features like annotation and the “assets” function enabling structured labelling of components in the scan.

Event analysis after health and safety incidents or process safety events usually involves multiple parties, some who may be unfamiliar with the site. 3D scans have been used during team discussions to give everyone contextual information of where the incident or event occurred and what was in the surrounding area. With Cintoo Cloud all users can benefit from collaboration of the various past versioning of reality data capture that took place . In addition, all involved parties have collaborative evidence of their work notes and history to fully support their efforts and work notes.

Placing Digital Twin ID's to assets using Cintoo Cloud

Future Opportunities and Challenges

3D model data opportunity

Genesis has plans to store 3D models in the Cintoo platform. This allows models to be superimposed on the scan data and viewed in context with the rest of the asset. An example of this functionality is shown below where a model of an elevated work platform was created from point cloud data captured while parked on site. The model can then be placed in the scan and moved around.

Cintoo provides an additional feature which speeds up the creation and integration of 3D models. A section of point cloud data can then be exported as a sold mesh enabling it to be directly opened in a 3D modelling software package.

Superimposing a 3D model generated object into the scan

Keeping the data up to date challenge

A frequently asked question about the data is “how will it be kept up to date?” In the short time since implementation there is a number of planned options as listed below in the order of least cost to most expensive.

- Annotation: Changes to plant can be annotated within the 3D scan platform in a similar manner to redline markups on technical drawings

- 360 photography: Updated panoramic photos of changes can be superimposed on the scan for minimal additional cost

- 3D model: 3D models of plant changes can be superimposed on the scan

- Updated scans: If the data continues to add value there may be a business case for conducting routine new scans as seen below.

Comparison of 3D scan image before and after a transformer replacement

Building Information Models (BIM) and Digital Twins

The work described in this paper is a small step on a comprehensive roadmap to take advantage of the latest asset information modelling paradigms and frameworks. Many other asset owners have tackled this with strategic initiatives like implementing Building information modelling (BIM) processes, software, standards and administration. Multiple vendors now offer digital twin platforms providing a single “pane of glass” to view and implement everything from real time asset data to drawings, predictive analytics, documentation, maintenance records, 3D models and scan data.

The approach presented in this paper was independently taken by Genesis and Meridian as it fulfilled their needs and business constraints. It required minimal internal resourcing to implement and had a short time frame from initiation to verifiable return on investment. Most importantly it does not prevent or hinder future roadmaps down a BIM or digital twin pathway as the data can be integrated, linked or migrated when needed.

Conclusions

New solutions such as Cintoo Cloud have initiated a paradigm shift where 3D scan data is treated as an asset that continues to add value long after its original purpose has been met. The solution presented may suit other asset owners looking for an economical sweet spot between the previous “use it then forget it” approach and the “gold standard” of building information modelling (BIM) more prevalent in green field development.

Large multi-disciplinary capital works are some of the immediate beneficiaries and collectors of 3D site data. Projects often complete an as-built 3D scan of the existing site at the beginning. On remote sites the savings identified below have been greater than more accessible locations. The technology does not eliminate site visits but enables them to be more targeted and informed, thereby reducing costs and time. In addition, users have found the scans complement site photography by providing context and reducing the quantity of photos needed to inform design work.

A simple approach to managing 3D scan data was presented based on independent experiences of both Meridian and Genesis Energy. It involved taking new and old 3D point cloud data previously stored in a range of undesirable locations and migrating it to a single cloud-based platform called Cintoo Cloud®. This unlocked the potential value of 3D Digital Twin and AEC BIM data for hundreds of people working on electricity assets long after it had served its initial purpose for a specific project.

Both companies experienced the use of 3D point cloud data being used for a range of use cases which reduced project time frames, costs, and risk while increasing collaboration. The signs of fruition are obvious, and a cultural change has been observed with greater usage of the data internally and externally to solve problems.

The success of this work opens many future opportunities and challenges including a shift to integrate 3D models, provide asset tours and keep the data up to date so it continues to add value. Some examples of realized benefits include continuity of design work through Covid-19 lockdowns, carbon emission reductions from less site travel and more informed communication between parties based on physical context.

Practical examples were presented of how 3D scan data was used long after the original capture to:

- Provide better Digital Twin context and data connectivity for assets and equipment

- Support better decisions by maximizing insight and understanding of asset condition

- Improve project engagement, planning and communication

- Save project cost while reducing risk

Project and Media Links

Learn more about Meridian Energy on their web site: https://www.meridianenergy.co.nz

Learn more about Genesis Energy on their web site: https://www.genesisenergy.co.nz