Background

Since Preston Haskell started his Jacksonville, Florida company in 1965, Haskell has played an instrumental role in leading design-build projects and the formation of the Design-Build Institute of America. This 100% employee-owned company with over $1.4 billion in annual revenue and 1,875 employees was given the daunting task of 3D modelling an entire football stadium for upcoming renovations and additions.

Their commitment to their customer, the Jacksonville Jaguars NFL football team, was to completely document their entire 27-year-old sports stadium to reflect the owners requirements. To optimally achieve this objective, Haskell planned to leverage 3D laser scanning including the latest SLAM technology, drone mapping, and Autodesk Construction Cloud for shared model authoring in their Scan-to-BIM process. And to enhance the workflows of reality capture, 3D modelling, and sharing their BIM and laser scan data of the stadium, Haskell would rely on employing Cintoo Cloud to upload and optimize the Scan-to-BIM process and downstream project stakeholders.

The Situation

The Haskell team plan was to capture an accurate digital representation of the stadiums existing condition to allow for facility feasibility studies regarding renovations and expansion for shade & rain coverage, improved air flow, and side concourses. In addition, better vertical transportation with increased space for football operations and replacing MEP are on the horizon. Due to years of fragmented ‘as-builts” with less-than-optimal documentation, an inside and out laser scan of the entire facility along with thorough documentation was needed so that a complete ‘as-built” model would be available to the stadium owner and any future AEC organizations in an easy to update format.

To this end, the game plan would consist of terrestrial scans with control points, SLAM scanning (Simultaneous localization and mapping) as well as Drone mapping. All scan results would then be uploaded to Cintoo Cloud for Scan-to-BIM evaluation and collaboration of applied work instructions.

Following their planed scan map with thorough scan documentation, a 3-man crew with four terrestrial scanners completed the site scans in under six weeks’ time onsite. This scanning plan included every possible space such as the areas below stadium seating and all precast columns, seating and raker beams as well as structured steel. All above ceiling areas were also required which resulted in 2.2 TB of structured scan data split into 52 zones. Click here to view a short video of this project process: Haskell Terrestrial Scans

For the photogrammetry site mapping, a drone was used for both the inner path of the stadium and the outer stadium path including aerial mapping from the top to the bottom of the stadium. For the higher structures that both terrestrial scanners and photogrammetry drone data did not suffice, a drone utilizing SLAM scanning provided the best capture approach. The results were 4 scans inside the stadium bowl and four outside which encompassed 440 million points for 4.3 GB of data.

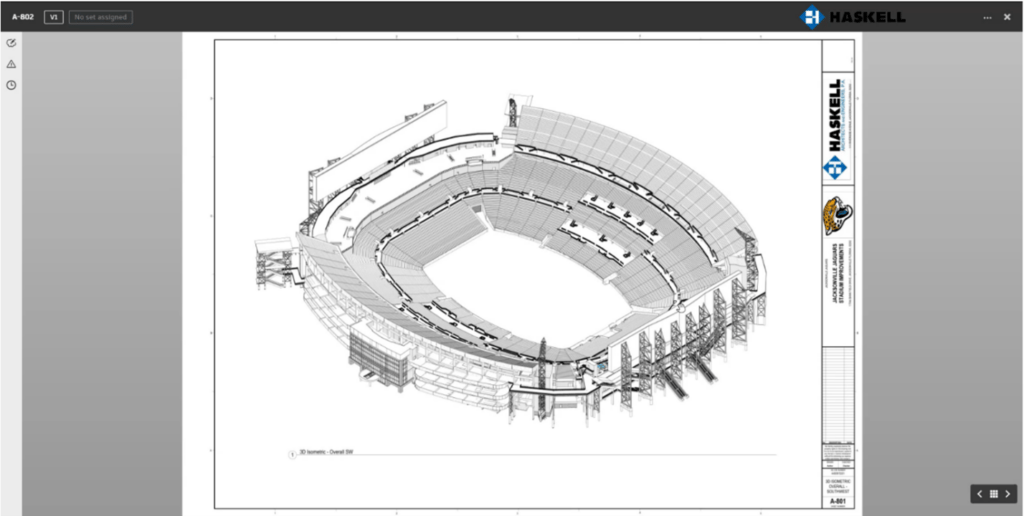

For the Scan-to-BIM project deliverable, two separate teams for structural and architectural modelling spent 12 weeks and 2,233 hours over 36 total review meetings to model all precast columns/seating, raker beams and structural steel as well as all floors, walls, ceilings, doors, windows, stairs, ramps and escalators. This resulted in full documentation of floor and ceiling plans, stadium sections, and 3D isometric views, all of which were easily uploaded into Cintoo Cloud. Management of these large scan files was conveniently optimized by Cintoo Cloud’s explicit folder creation and naming capability which also provides for as needed access based on need.

View the short video for this aspect of the project here: Site mapping

Workflows Used

Laser scanner: Trimble X7,

SX-10, Faro S70, S150

BIM 360, BIM Track

Point cloud software:

Trimble RealWorks, Recap

Pro

Modeling software: Revit

Results

Taking advantage of the integral integration of Cintoo Cloud to Autodesk Construction Cloud’s BIM Track and linked BIM 360 RVT files, the models were reviewed weekly for accuracy. The 13 Haskell team members responsible for the model development were working across 3 regional offices, with Cintoo Cloud facilitating concurrent work efforts with full access by all team members. This allowed easy integration between the remotely located Structural and Architectural Modelling teams to stay in sync throughout the entire project.

The 2,200 hours of modelling resulted in a 1.4 GB structural model and a 1 GB architectural model, all stored, organized and easily accessible on Cintoo Cloud.

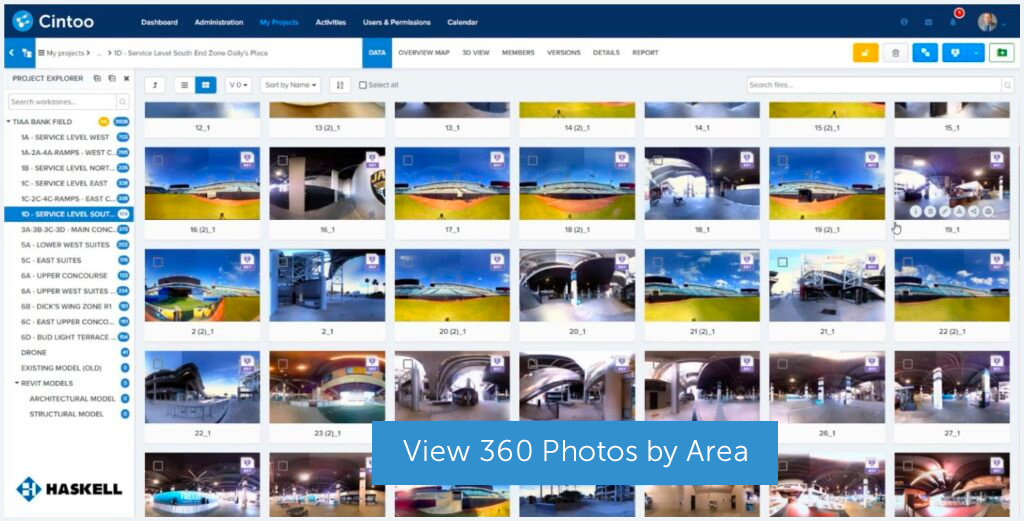

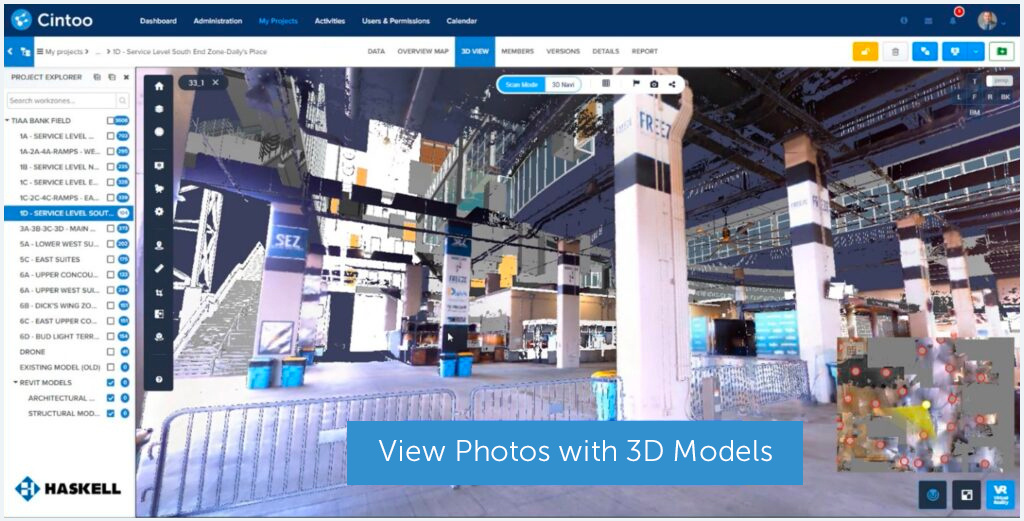

Area breakouts were created by level to allow fast sorting of the large database by the modelers, including the overview map of 360 photos, similar to Google Maps Street View experience, for all users’ benefit. Cintoo Cloud 3D views of point cloud and 360 photos was of great benefit to the team so they could walk or rotate thru the captures. Cintoo Cloud also provided the ability to toggle through the Revit models to verify the model in progress matches to the scans for consistent and repeatable comparison reviews.

The Cintoo visual comparison tool displayed what was and what was not modelled based on color-coding. Cintoo also provided a slider feature to display only the 360 models or the Revit models as well which optimized the work of the model and QC teams.

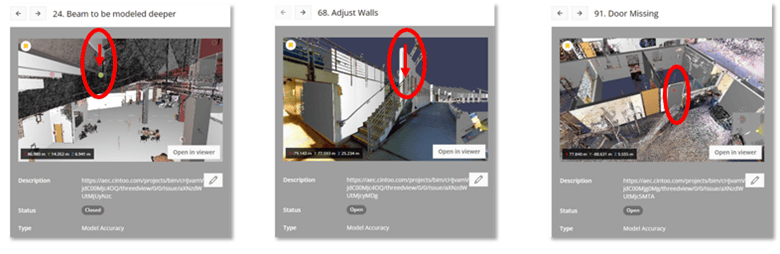

All Revit files were inherently updated in Cintoo Cloud for issue tagging within the models such as precast variances or missing doors and then easily published into the Autodesk Construction Cloud + BIM Track issue report that is integrated within Cintoo, as shown in the following image.

With intricate advanced planning and utilizing Autodesk Construction Cloud in concert with Cintoo Cloud and the latest scanner technologies, the scanning of such a mammoth project was completed in record time and the model detailing all existing conditions met all of the clients and their building design teams expectations.

By using Cintoo Cloud and its unique point cloud-to mesh technology to easily upload, manage, collaborate, and store the large scan files, all responsible parties were able to efficiently execute their work with no delays or encumbrances. By employing Cintoo Cloud’s inherent scan-to-BIM features the teams were able to uncover critical details such as stadium seats that obstructed precast riser heights. In addition, subsequent design and build teams now had a reliable library and tool in Cintoo Cloud to continue this major renovation feasibility study.

Going Forward

The Haskell stadium team clearly demonstrated to their client and the subsequent design and build teams that Cintoo Cloud has a positive impact for optimizing Reality Capture for many of their projects.

Going forward, design and build teams are able to easily review the facilities scanned results year after year, planning new projects with clients without having to call up data from the archives.

The 3D model is providing enhanced “as-built” digital drawings including the ability to implement and compare BIM and CAD models with inherent and easy workflows for planning and design.

Now, the Haskell teams and their clients can access their data within seconds on the secure cloud, rather than waiting on hard drive mailings to project stakeholders. Additionally, their teams and clients including subsequent contractors can interact over the web with the easy-to-use platform without having to add and learn new software applications which are not integrated into the Autodesk Construction Cloud platform.