What do you need to do?

![]()

Improve Asset Visibility and Digital Twin Management

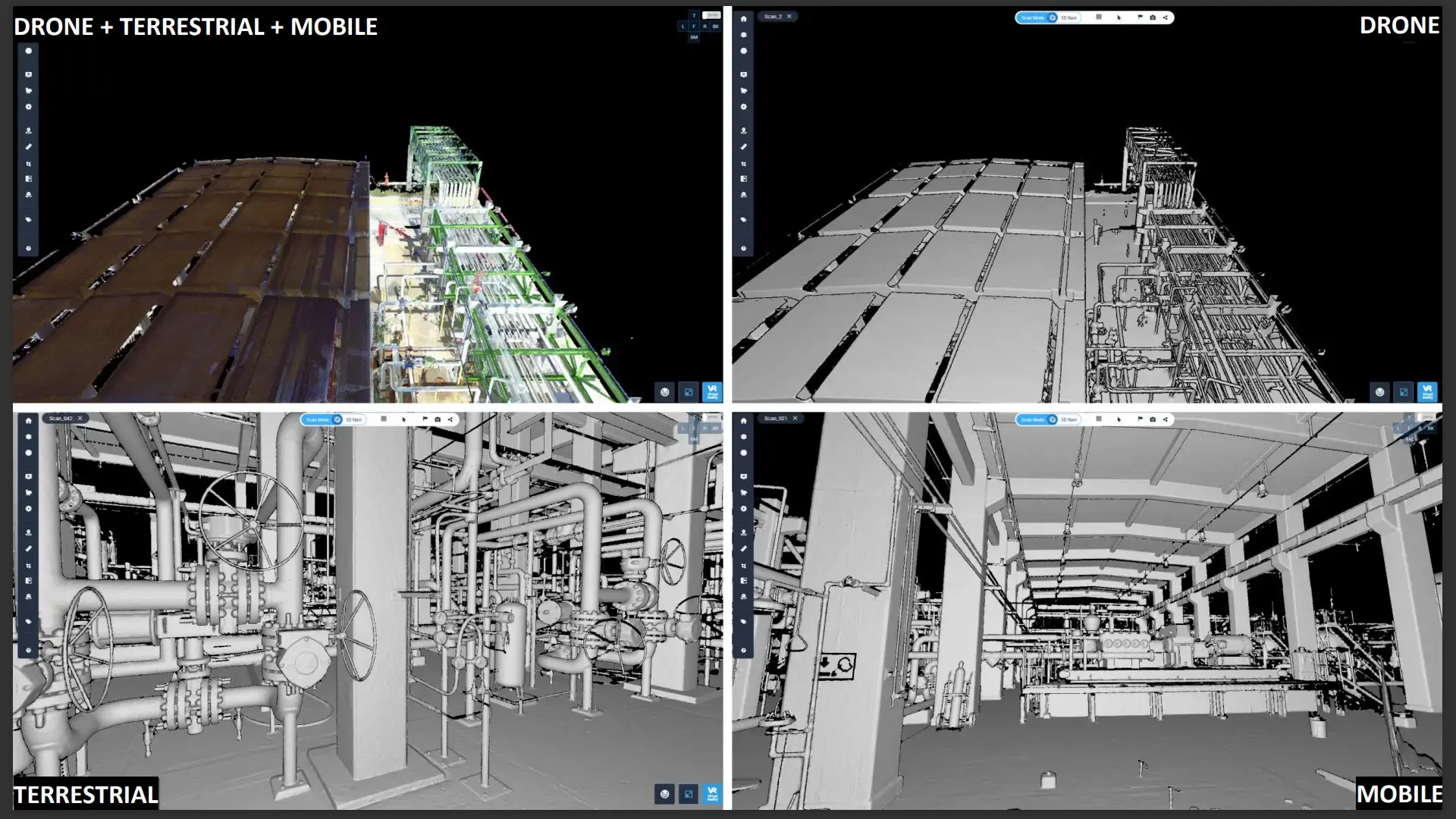

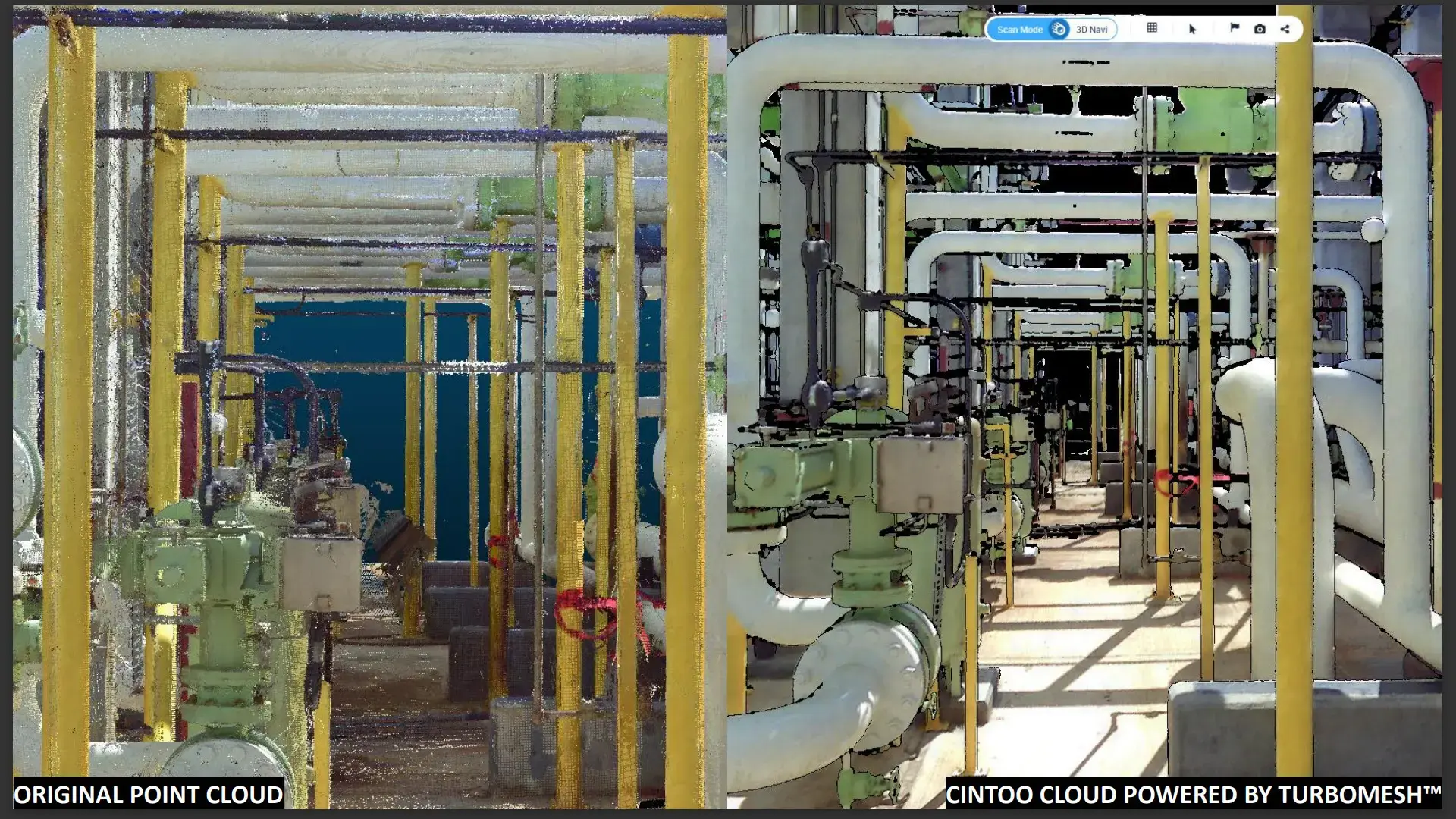

With the Twin Edition, manage complex environments in a high-fidelity mesh setting with no compromise to accuracy. Collaborate through an accurate digital twin of the as-built conditions that eliminates the need for onsite visits and streamlines global collaboration. Don't get locked in; navigate to any virtual vantage point and utilize different scanning types and platforms.

Maintain a single source of truth that allows teams to understand facility layouts and equipment behavior virtually. This means that maintenance is easier to facilitate too, optimizing ROI further down the road.

- Simulate safety procedures and emergency protocols without putting personnel at risk.

- Perform predictive maintenance.

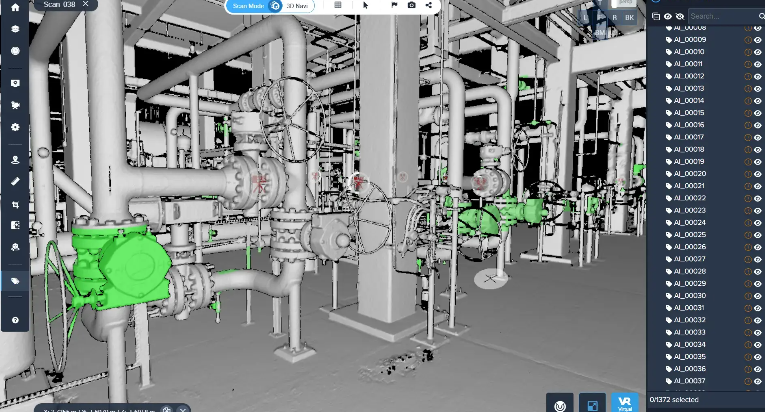

Asset tagging allows teams to mark, track, annotate, and inspect equipment virtually. Teams can monitor asset health, evaluate installations, and classify pipelines and process flows for a holistic view of the site.

- Display your assets and equipment in their existing conditions to make the right maintenance decisions.

- Tag your assets using Cintoo's AI engine and classify them.

- Connect your asset and equipment to your business information system.

A centralized data repository ensures that all stakeholders work from the same source of truth. This unified approach enhances communication, reduces miscommunication, and supports better project execution.

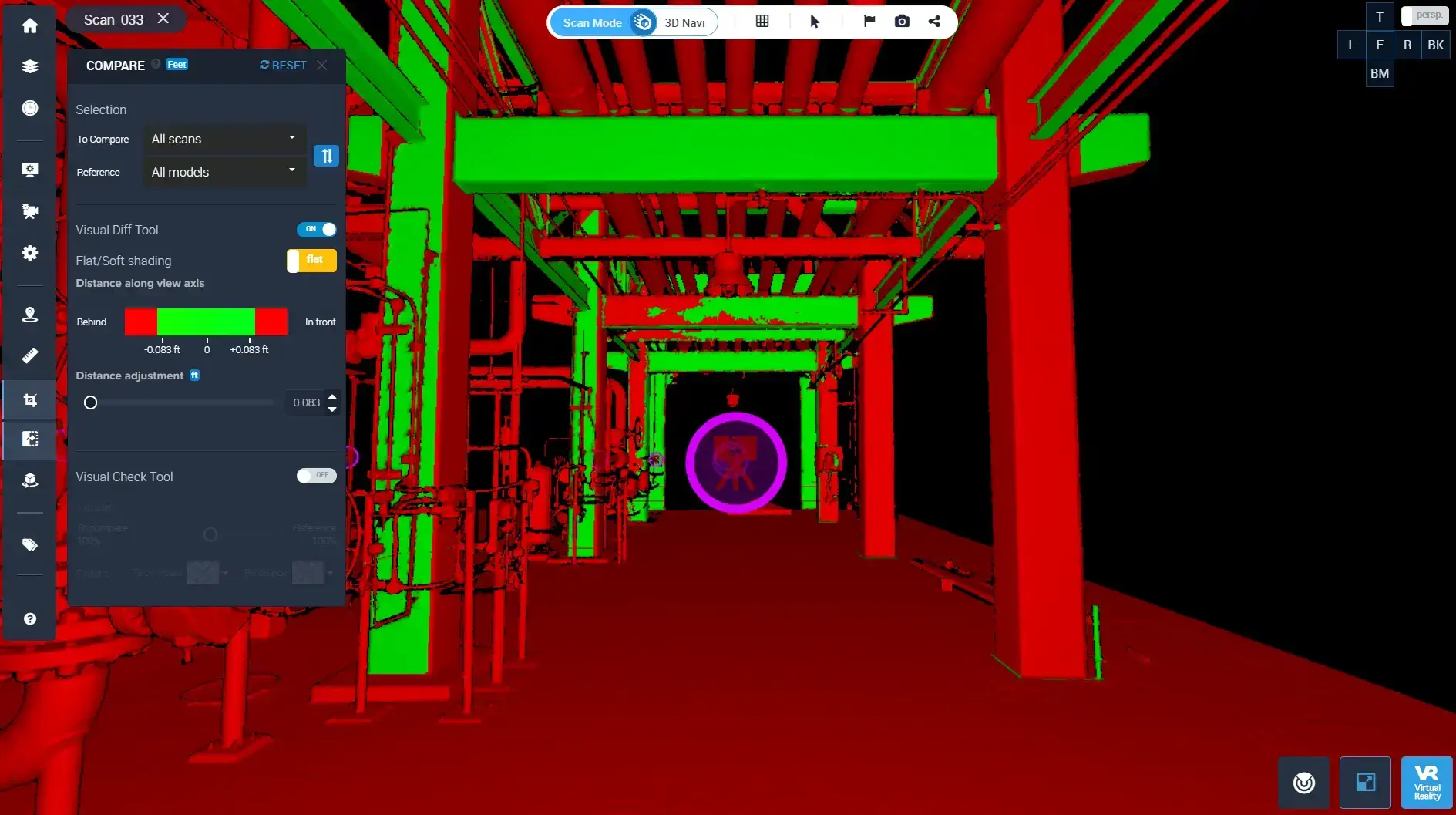

- Easily upload scan data from any hardware set, overlay models for precision, and detect clashes before they occur.

- Improve your QC process and assured compliance with integrated visual comparisons of scans to 2D and 3D models.

Uncover a myriad of ways you can leverage your 3D scan data

in our platform to achieve your objectives.