Digital twins from laser scans are rapidly transforming how organizations understand, manage, and optimize physical environments. From construction and engineering to manufacturing, and facilities management, laser‑scanned digital twins provide a living, data‑rich replica of the real world.

As industries move toward automation, predictive analytics, and AI‑driven decision‑making, the demand for highly accurate spatial data has never been higher. Highly accurate spatial data is what these AI and analytics driven systems feed on. Laser scanning technology, combined with advanced modeling software, makes it possible to create digital twins that are not only visually precise but also analytically powerful.

In this article, we’ll explore what digital twins from laser scans are, how they’re created, why they matter, and how organizations can leverage them for long‑term value.

A digital twin is a virtual representation of a physical asset, environment, or system that mirrors its real‑world counterpart. When digital twins are created from laser scans, they are built using highly accurate 3D data captured through technologies such as LiDAR or terrestrial laser scanning.

Laser scanners emit millions of laser pulses per second, measuring the time it takes for each pulse to bounce back. The result is a point cloud—a dense collection of spatial data points that precisely map surfaces, geometry, and spatial relationships, providing the digital twin version.

This point cloud becomes the foundation for:

The result is a digital twin that reflects reality as it truly exists.

Not all digital twins can be the same accuracy-wise. In fact, many variations of a digital twin can exist. However, digital twins from laser scans stand out because of their unmatched accuracy, completeness, and reliability and this will make the AI and analytics dependencies that much more efficient to work off of.

Key advantages include:

For organizations managing high‑value assets or safety‑critical environments, these benefits make laser‑derived digital twins the superior form.

Creating a digital twin from laser scans typically follows a structured workflow:

Terrestrial, mobile, or aerial laser scanners capture millions to billions of data points.

2.Point cloud processingRaw scan data is registered, cleaned, and aligned to create a unified coordinate system.

3. Model development

The point cloud is converted into usable formats such as 3D meshes, CAD models, or BIM models. In Cintoo, the point cloud is converted to a high-fidelity 3D mesh, making the cloud-based data easy to navigate and accurate.

4. Data enrichment

Metadata, asset information, sensor data, or operational parameters are added to the model. Cintoo also allows for this bidirectional data flow based off the 3D scan data.

5. Integration with platforms

The digital twin is connected to analytics tools, facility management systems, or simulation software.

This process transforms static geometry into a dynamic, intelligence‑ready digital asset.

Construction and Engineering

Digital twins from laser scans help teams validate as‑built conditions, reduce rework, and improve coordination between trades. They also support clash detection and construction progress tracking.

Facilities Management

Facility managers use laser‑based digital twins to manage space utilization, plan maintenance, and visualize building systems without invasive inspections.

Manufacturing and Industrial Sites

In complex plants, digital twins enable layout optimization, safety planning, equipment retrofits, and downtime reduction without interrupting operations.

Infrastructure and Transportation

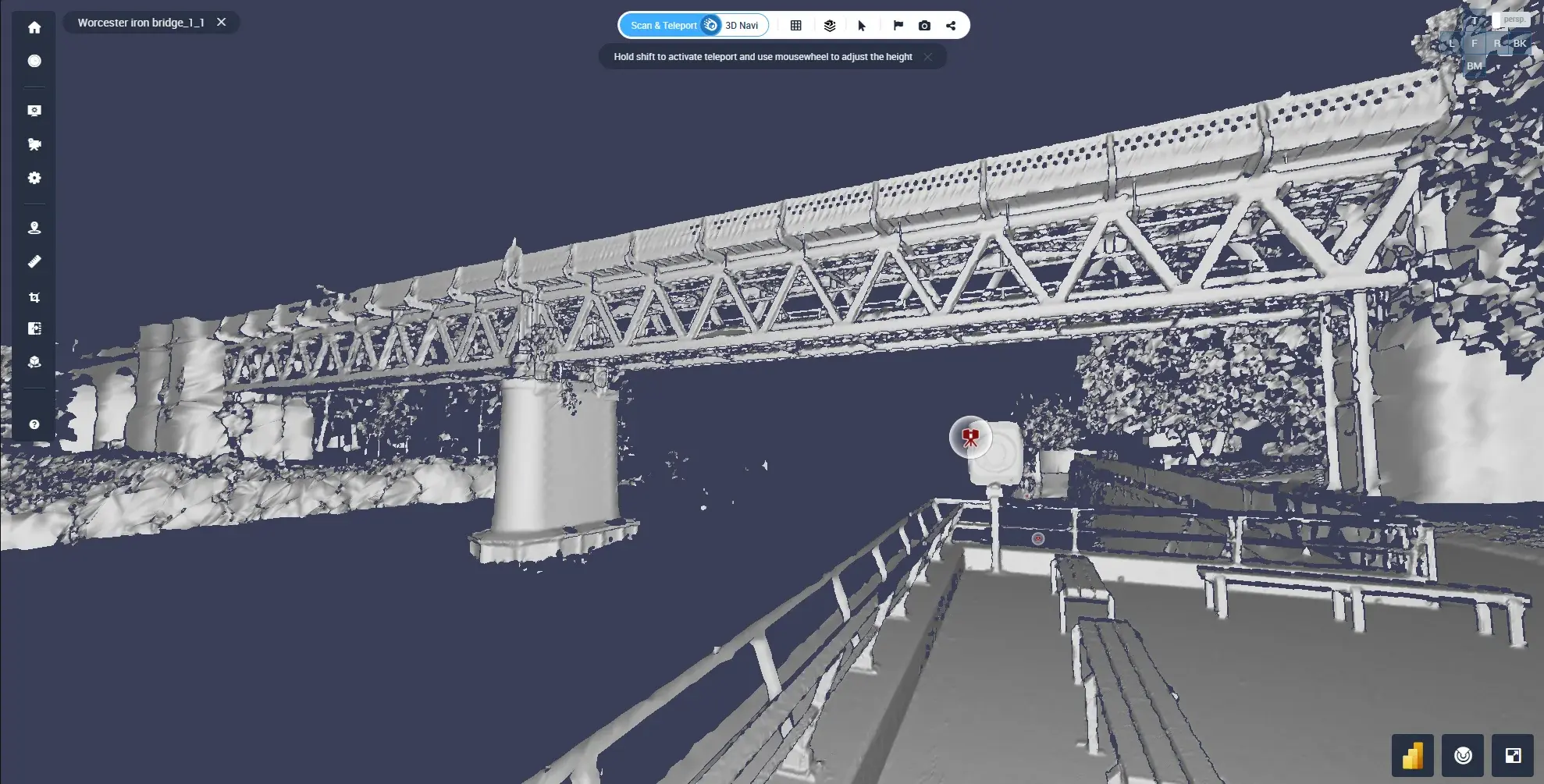

Bridges, tunnels, rail systems, and airports benefit from scan‑based digital twins that support inspection, lifecycle analysis, and future upgrades.

Smart Cities and Urban Planning

City planners use digital twins to analyze traffic flow, environmental impact, and infrastructure resilience using accurate 3D city models.

AI systems rely on high‑quality data. Digital twins from laser scans provide structured, spatially accurate datasets that AI models can trust.

When paired with AI, scan‑based digital twins enable:

Because laser scans capture objective reality, they reduce bias and uncertainty in AI‑driven insights. This makes them especially valuable for mission‑critical decision‑making.

One of the most overlooked benefits of digital twins from laser scans is future readiness. Once the real world is captured in high resolution, organizations can adapt the same data for emerging technologies such as:

In other words, laser‑based digital twins can enhance an organization’s digitization and analytics-driven strategy behind the first iteration of the data.