Revolutionizing Supply Chain Management with Digital Twins

- Madeline Medensky

- March 11, 2025

Discover how digital twins are transforming supply chain management in the automotive industry, driving efficiency and innovation like never before.

The Rise of Digital Twins in Supply Chain Management

Digital twins are swiftly becoming a cornerstone in the automotive industry, particularly in supply chain management. By creating a virtual replica of physical assets, processes, and systems, digital twins facilitate real-time monitoring, diagnostics, and prognostics.

This approach revolutionizes how automotive manufacturers interact with their vendors and manage their supply chains, offering unprecedented visibility and control over every aspect of the production process. Enhanced collaboration and data-sharing capabilities among all stakeholders result in improved efficiency, reduced costs, and higher product quality. For instance, because of the use of digital twins for seamless collaboration in a virtual setting, automotive suppliers and vendors can expect a 20–40% increase in productivity across design, inspection, and manufacturing processes. More specifically, a Tier 1 supplier saved $500,000 in potential rework costs in a single year by using 3D scan data to populate a digital twin of the site facility, which was then used for real-time quality assurance.

In this blog, we'll delve into all aspects of supply chain collaboration as optimized and facilitated by the use of digital twins to create smart factories.

Collecting Laser Scan Data: The First Step

The journey towards an effective digital twin begins with collecting accurate and high-fidelity laser scan data. This data serves as the foundation upon which the digital twin is built, capturing intricate details of manufacturing facilities and equipment.

Laser scanning provides a comprehensive and precise 3D representation of the physical environment. This enables stakeholders to make informed decisions and plan modifications with confidence. The high-resolution data ensures that even the smallest details are captured, paving the way for a robust digital twin.

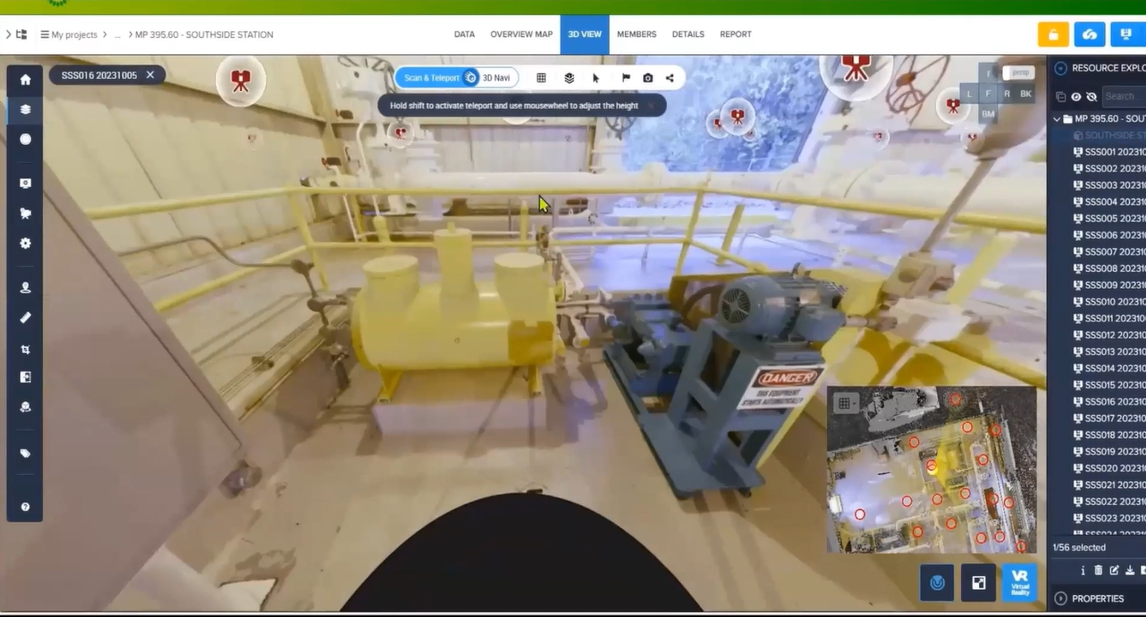

In one example, General Motors used laser scanning (more specifically terrestrial LiDAR scanners) to ascertain the layout conditions and details of their Bedford factory. Using 3D laser scanning to create a digital twin, they were able to navigate to any area on the plant floor in the virtual setting. "With high fidelity imagery, really that immersive feeling, you can get anyone in that plant. The intuitiveness of being able to navigate very much like a Google Street View is incredibly important and beneficial for us because we can share this project with our vendors and they can get access to the virtual plant too," says John Brown, Head of Reality Capture at GM.

Laser scans are streamed at the same resolution as the source scanner.

The potential for digital twins to streamline supply chain interactions is dependent on the platform used to upload and stream the laser scan data. Supply chain interactions can become more productive through the digital twin only when the laser scan data is streamed using a platform that is accessible, intuitive, and optimized with the right tools.

Populating a Digital Twin: Seamless Integration with Cintoo

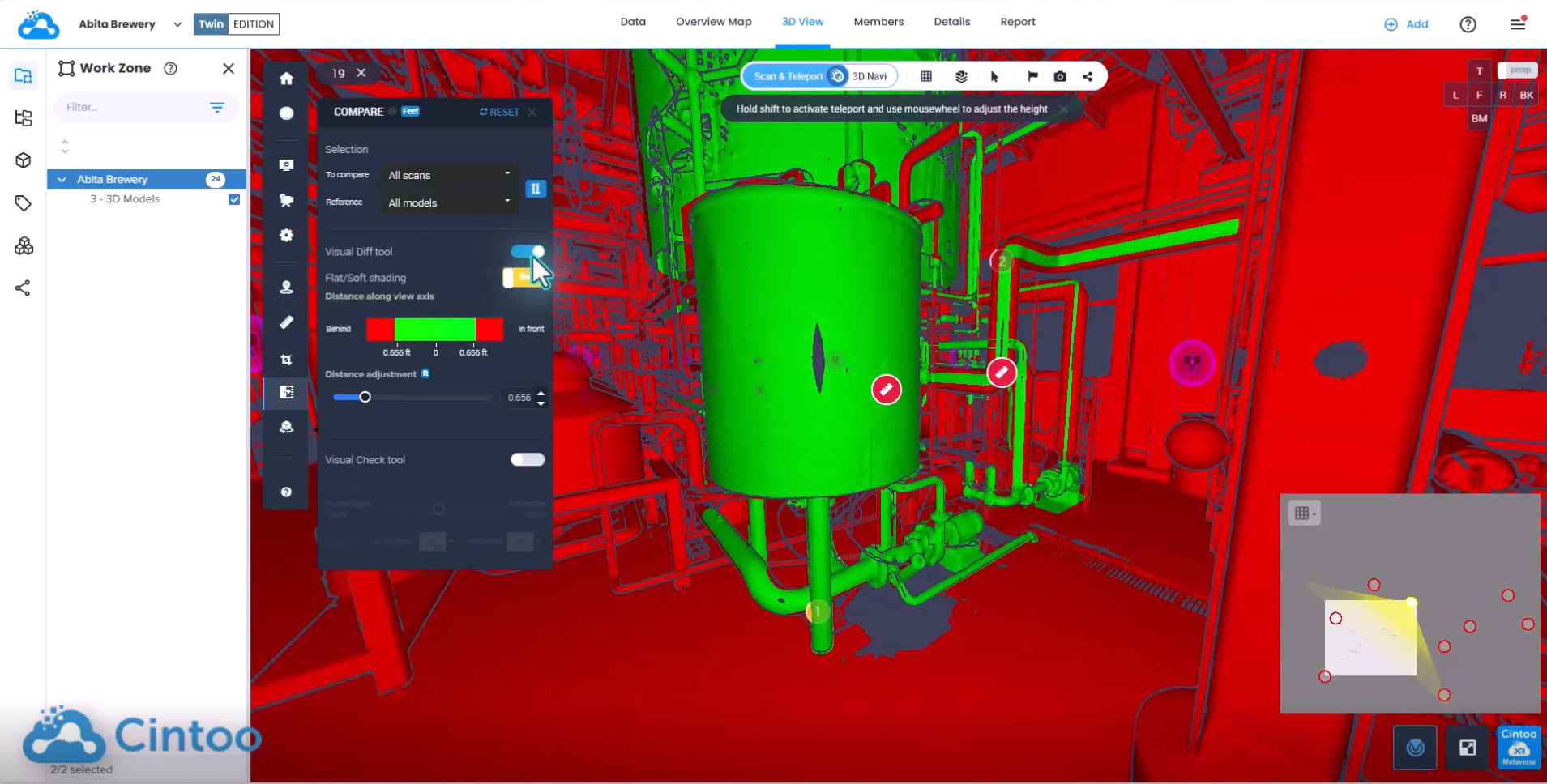

Once the laser scan data is collected, it must be integrated into a digital twin platform. Cintoo offers a seamless solution for this process, converting massive point cloud data into a cloud-based, accessible format. This makes the data actionable and easy to navigate.

Cintoo's platform enables users to drill down from a map level to a specific plant floor, offering high-fidelity imagery that is both immersive and intuitive. This capability is akin to a Google Street View for manufacturing facilities, making it an invaluable tool for engineers and suppliers. As John Brown from GM says, "Using Cintoo allowed us to put the keys back in the hands of the engineer. They're able to do quick assessments in the platform, using the digital twin to validate CAD models on the fly. Same thing with vendor interactions. If we know an equipment piece needs to be tested to the as-installed conditions first, we can go into Cintoo with that equipment model and overlay it to the real conditions so we can see if it matches."

John Brown from GM explains how modelled equipment can be streamed in the smart factory to detect clashes instantly.

Cintoo offers others tools to help project teams optimize their smart factories. Navigational abilities and site views, like the conversion to 3D solids, allows users to interpret the virtual factory accurately. Automatic measurements and annotations can be made in the platform. AI-enhanced asset tagging is also becoming an innovative tool for users to monitor and maintain all important equipment pieces assembly lines.

Streamlining Operations: Making Data Actionable

The true power of a digital twin lies in its ability to make data actionable. With Cintoo, engineering teams can quickly assess whether their CAD models align with the actual point cloud data, significantly compressing start-up times for various tasks.

The platform's user-friendly tools allow for quick measurements and assessments, putting the power back in the hands of engineers. This not only speeds up project timelines but also ensures that all stakeholders have accurate, up-to-date information, enhancing overall operational efficiency.

Future Prospects: The Evolution of Digital Twins in the Automotive Industry

The future of digital twins in the automotive industry is incredibly promising. As technology continues to evolve, the capabilities of digital twins will expand, offering even greater benefits to supply chain management.

The integration of digital twins with advanced analytics and AI will facilitate more predictive and prescriptive insights, further reducing downtime and optimizing resource allocation. The ongoing development of these technologies will continue to drive innovation, making supply chain management more dynamic and efficient than ever before.

.png?width=1080&height=500&name=CTA%20e-book%20Digital%20Twin%20-%20blog%20Cintoo%20(2).png)