Enhancing Construction Workflows: 3D Scan Progress Monitoring Techniques

- Madeline Medensky

- May 28, 2025

The Digital Shift in Construction

The construction industry is undergoing a major digital transformation. Technologies like Building Information Modeling (BIM), laser scanning, and cloud-based collaboration tools are no longer optional—they're essential. One of the most impactful developments in this space is 3D scan progress monitoring, a workflow that uses scan-to-model comparisons to provide accurate, real-time insights into the status of construction projects.

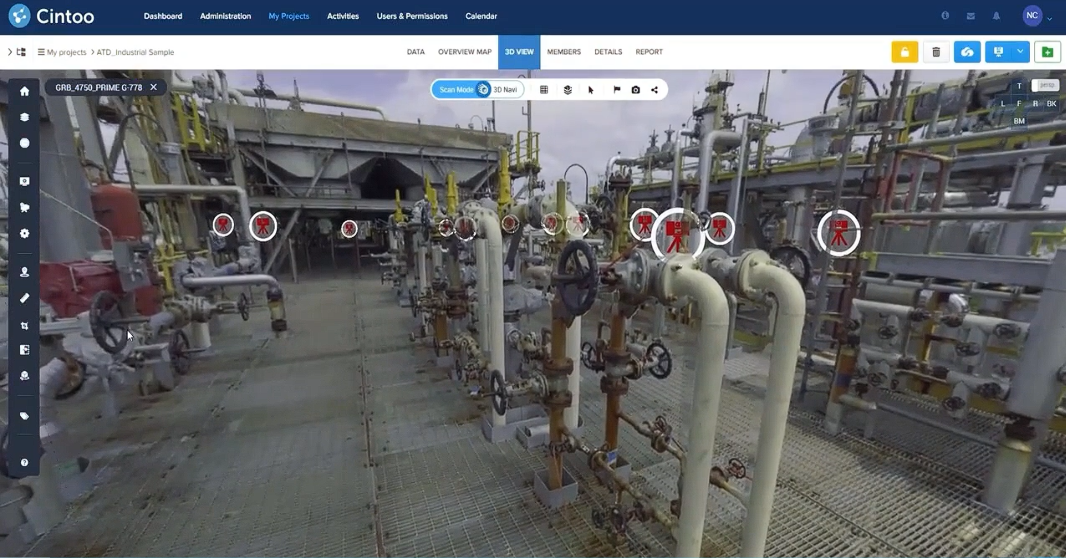

In traditional construction workflows, tracking progress involved manual inspections, paper checklists, and subjective assessments. Today, reality capture technologies allow construction teams to evaluate what has actually been built and compare that against the design model. This process, known as progress monitoring, is transforming construction oversight, bringing a level of accuracy and visibility never before possible.

What is 3D Scan Progress Monitoring?

3D scan progress monitoring is the process of comparing reality capture data—typically generated using terrestrial laser scanning or drone photogrammetry—to a digital design model. This data comparison yields objective, quantifiable metrics such as coverage percentage, distance to model deviations, and construction status by model element.

This method allows construction teams to track how much of the project is completed, what remains under construction, and whether the as-built reality aligns with the intended design. The result is improved transparency, earlier detection of issues, and better alignment across all project stakeholders.

How Progress Monitoring Works

A successful 3D scan progress monitoring workflow begins with data preparation. Construction teams visualize the latest 3D scan data, ensuring that only relevant portions of the site are included. Next, they select a digital model or specific model elements to compare with the scanned data. A key parameter in this process is the tolerance value—the distance within which scan points must fall to be considered a match with the model.

Once initiated, the platform runs a scan-to-model comparison algorithm and generates a detailed report. This report is downloadable in spreadsheet format and includes values such as model element names, element IDs, coverage by scan data (expressed as a percentage), and minimum, average, and maximum distance values between model and scan.

The output data can be used to identify not-built elements, partially completed elements, or elements that have exceeded tolerances, helping teams make informed decisions. This scan-to-model comparison offers a far more objective measure of progress than visual checks or manual documentation.

Benefits of 3D Scan Progress Monitoring in Construction Workflows

Accurate, Data-Driven Insights

According to McKinsey, large construction projects are typically delivered 20% late and up to 80% over budget. These inefficiencies are often the result of miscommunication, delayed detection of issues, and lack of real-time visibility. With 3D scan progress monitoring, project managers receive quantitative feedback on construction status, allowing for better decision-making and faster corrective actions.

Time and Cost Savings

Manual inspections are time-consuming and prone to error. Automating progress reports reduces site visits and administrative overhead, freeing teams to focus on value-added tasks. For instance, comparing scan datasets captured in consecutive months can instantly reveal which components have been added or completed, streamlining construction verification.

Enhanced Collaboration

Progress monitoring tools enable stakeholders to visualize discrepancies between the model and the reality, regardless of their location. This digital transparency promotes accountability and streamlines issue resolution across architects, contractors, and owners.

Improved Risk Management

Identifying discrepancies early reduces the risk of costly rework and change orders. Progress monitoring helps detect schedule deviations before they impact downstream activities, supporting proactive project controls.

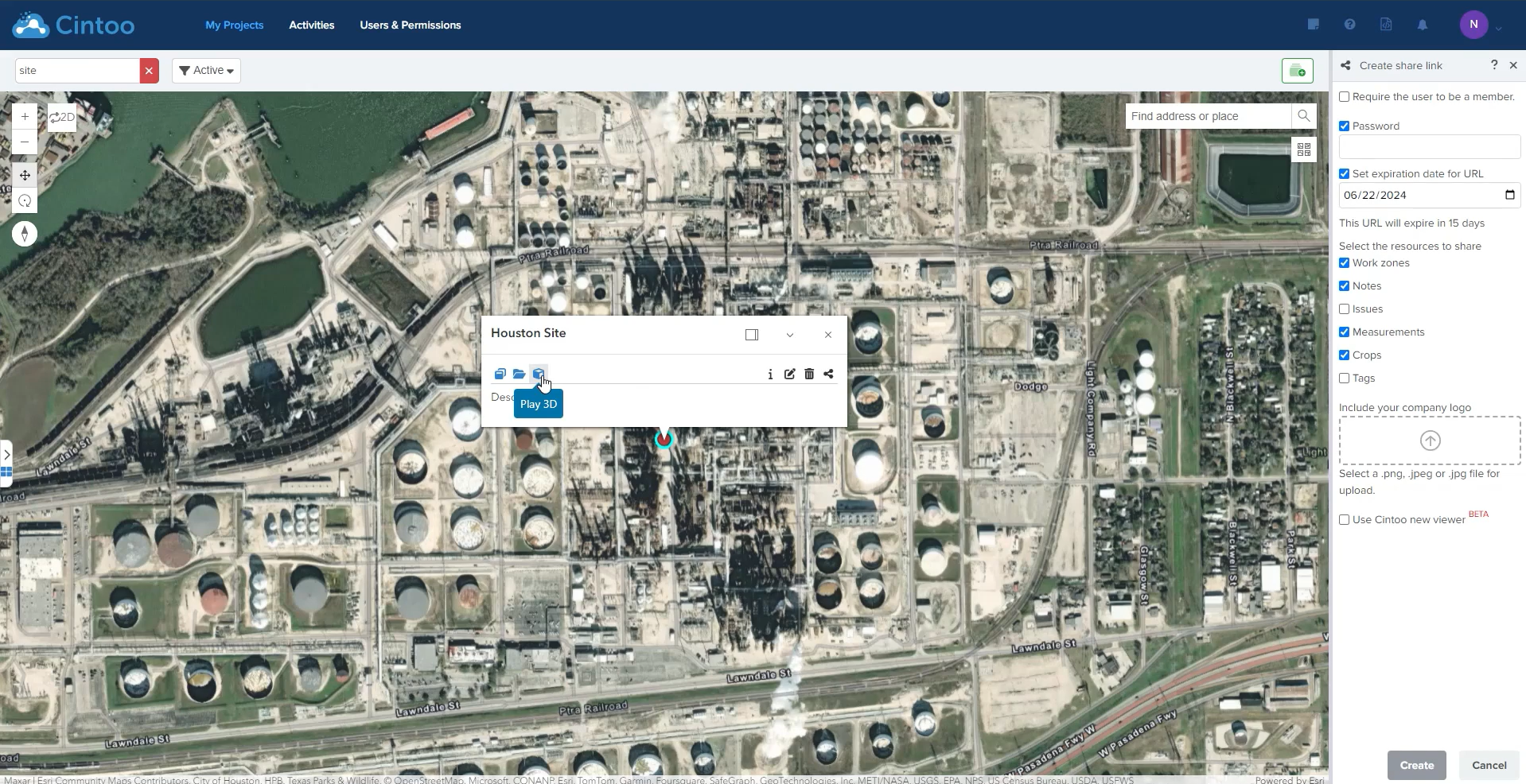

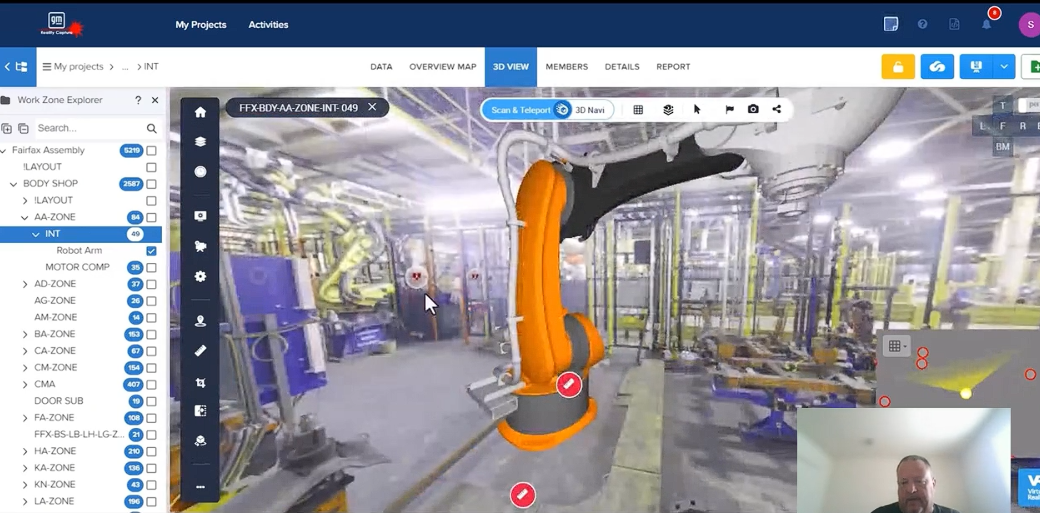

Integration with BIM and Digital Twin Platforms

Most progress monitoring platforms support industry-standard file formats such as Revit, IFC, and Navisworks. This interoperability ensures that the workflow complements existing BIM processes. The resulting data can also feed into digital twin systems for lifecycle management and facility operations.

Use Cases and Practical Applications

One common use case is tracking structural elements such as columns and beams. By selecting these components in the digital model, teams can run targeted comparisons with scan data from different phases of the build. This enables them to verify which elements are in place and whether they meet the required tolerances.

Another application is trade-specific reporting. Teams can isolate elements by discipline—mechanical, electrical, plumbing—and generate separate progress monitoring reports. This provides more focused analysis and enables subcontractors to validate their own scopes of work.

Reports can also serve as digital documentation for milestone verification, payment applications, or regulatory compliance. The output spreadsheets include element IDs and metadata, making it easy to cross-reference with model viewers or external tools.

Best Practices for Implementing Progress Monitoring

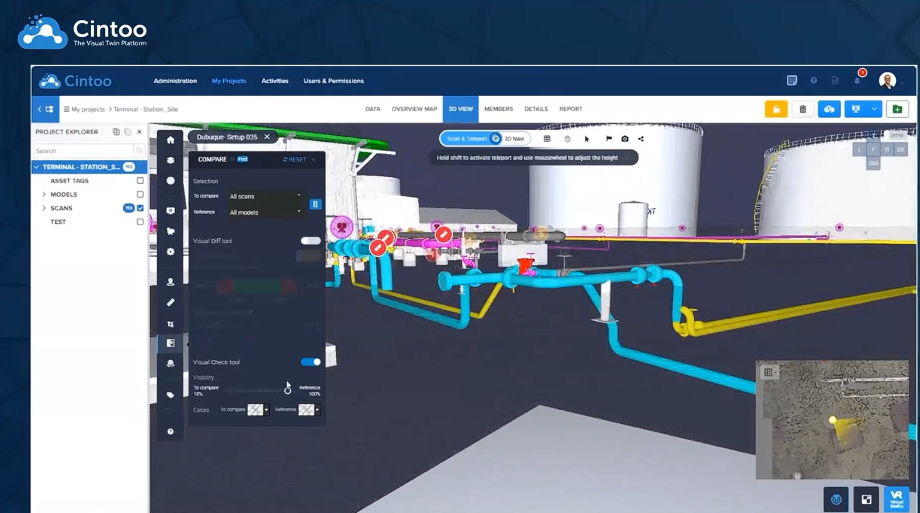

To get the most value out of 3D scan progress monitoring, construction teams should establish dedicated work zones for managing their progress files. Before launching a comparison, it’s important to configure the project units and measurement precision in alignment with project standards. These settings affect the interpretation and accuracy of the resulting data. All of this can be done in Cintoo easily.

Diversifying progress monitoring runs by discipline or construction zone can yield cleaner, more actionable data. It’s also advisable to plan scan intervals according to project phases—weekly, biweekly, or monthly—depending on the construction pace and project complexity.

Lastly, tolerance values should be tailored to the elements being evaluated. Higher tolerances may be acceptable for large components like walls, while tighter thresholds should be used for high-precision elements like piping or fixtures.

A Subtle Look at the Tools Making This Possible

There are several tools on the market that enable 3D scan progress monitoring, offering automation, flexible import options, and customizable reporting. Some of these platforms also support model search functions, model element highlighting, and scan overlay visualization. While each solution offers different features, the overarching goal is the same: to deliver fast, reliable, and meaningful insights into construction progress using 3D data.

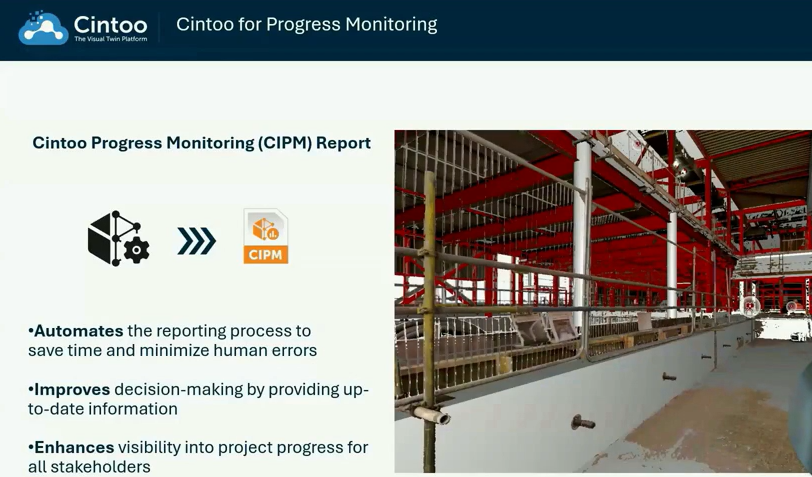

Cintoo allows users to upload scans and models in multiple formats, run tolerance-based comparisons, and receive spreadsheet reports that can be used for further analysis or stakeholder presentations. These tools continue to evolve, adding support for more model types, metadata, and cloud collaboration features.

The Future of Construction Progress Tracking

As more firms adopt 3D scanning and digital workflows, progress monitoring will become a standard part of project controls. The combination of real-world accuracy, rapid reporting, and cloud accessibility sets a new benchmark for how construction progress is measured and managed.

Digital progress monitoring is not just about comparing data—it’s about enabling smarter construction. It helps project teams move away from guesswork and toward precision. In an industry where time, budget, and quality are always on the line, having a digital, scan-based workflow in place offers a clear advantage.

For construction professionals looking to modernize their workflows and gain deeper insights into project status, now is the time to adopt 3D scan progress monitoring. It’s not just a trend—it’s the foundation of the future of construction management. Watch Cintoo's demo on progress monitoring now!