This One Key Insight Will Help You Maximize Your Industry 4.0 Workflows

The use of photogrammetry to ascertain the as-built conditions in construction and design projects goes back several decades. That much isn’t new, but what is new is how people are utilizing point cloud data for today’s projects.

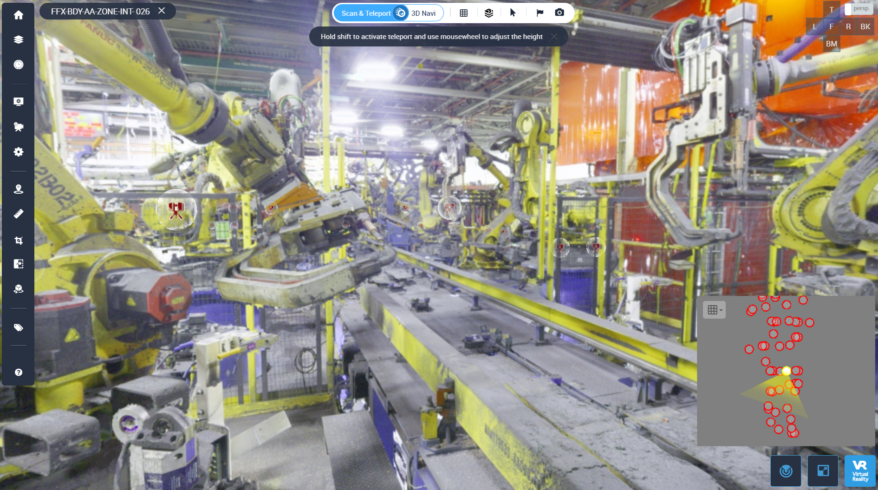

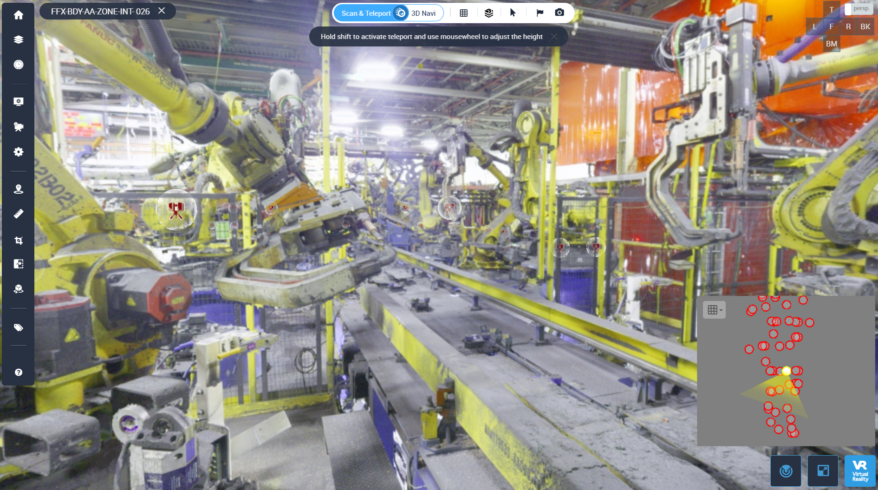

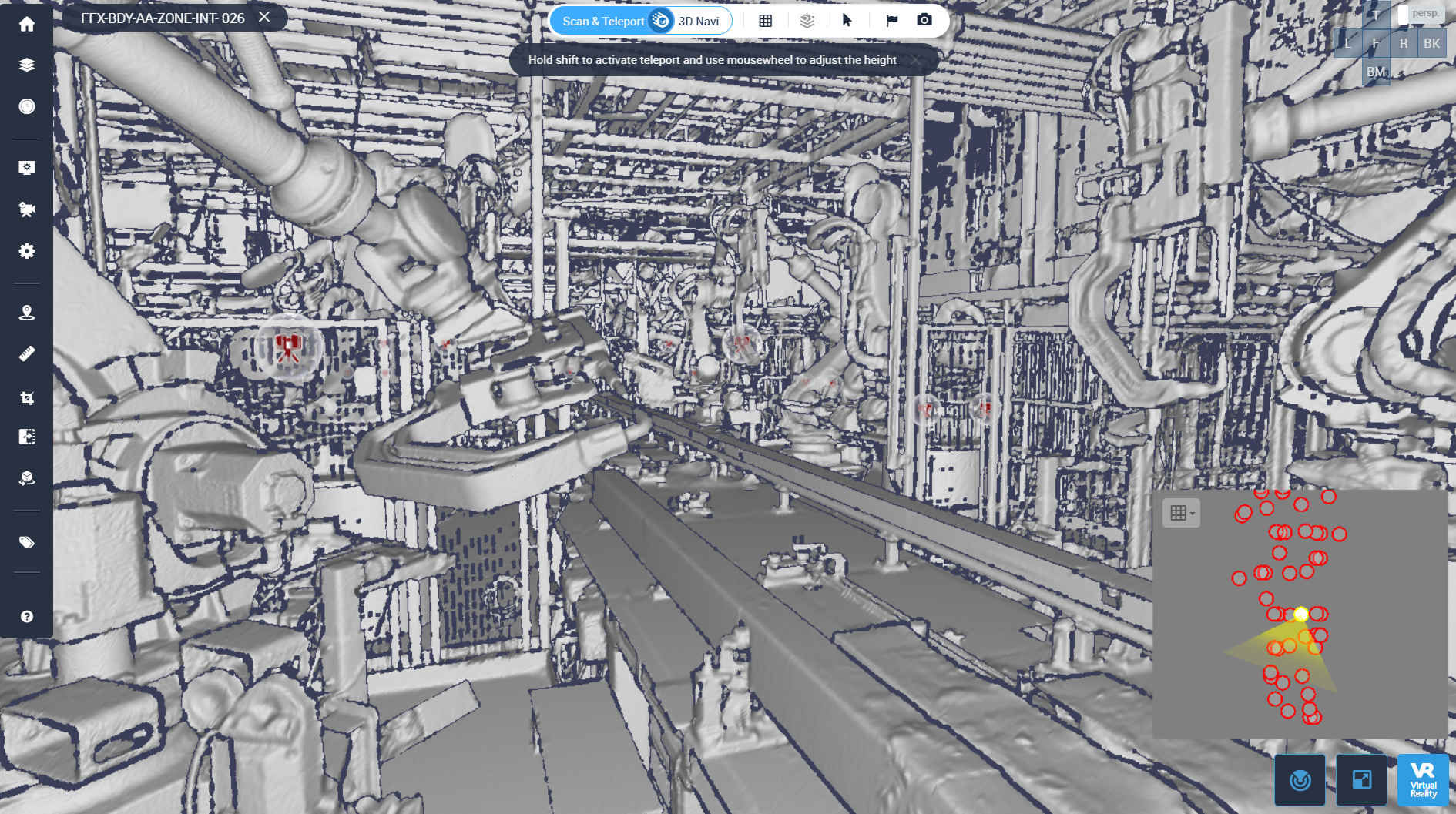

As John Brown, a Supervisor at General Motors’ Reality Capture division, says, “Cintoo for us has really democratized point cloud data so that it becomes the deliverable standard. Our engineers are leveraging these data sets regardless of what region they’re in, could be South America, China, India, Korea, it’s really made us even more of an international company from an engineering standpoint.”

When you prioritize 3D data visualization as the go-to method on all construction and build projects and renovations, the standards for improved efficiency and collaboration are increased. Cintoo helps you do this on all projects small and large by helping you make sense of why having a visual twin is necessary for improvement, saving time and money.

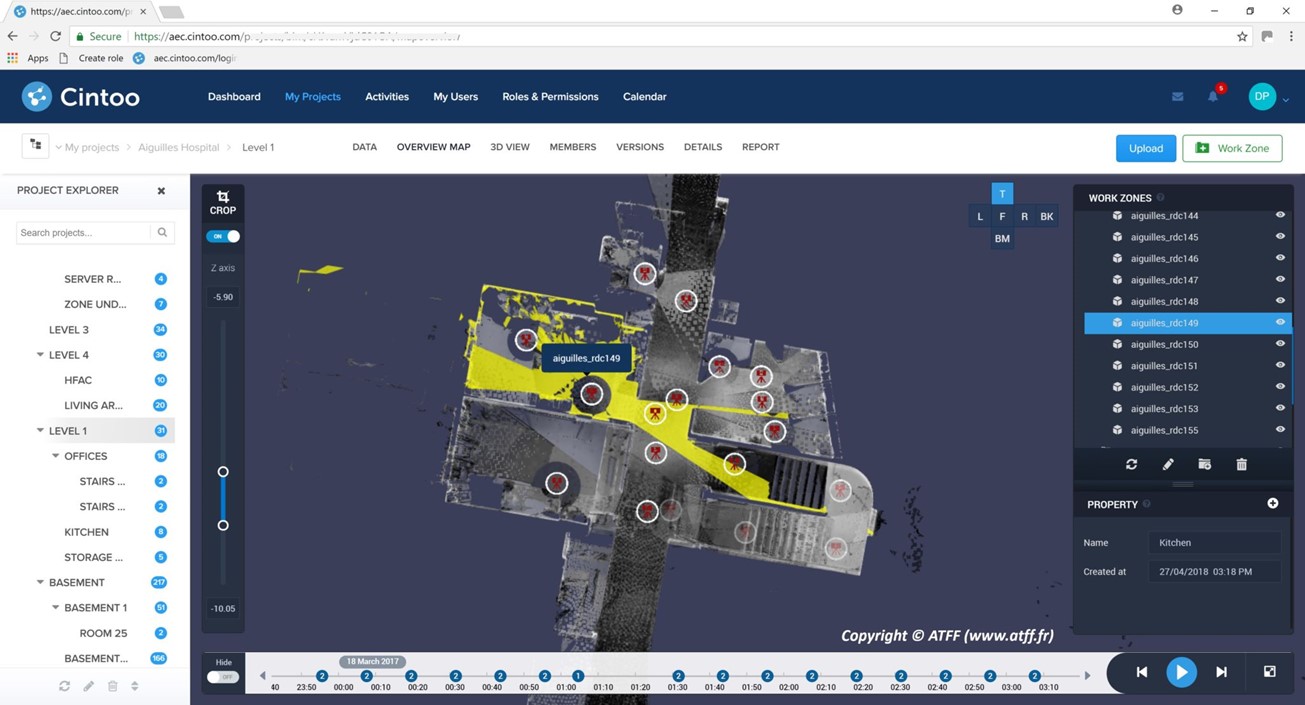

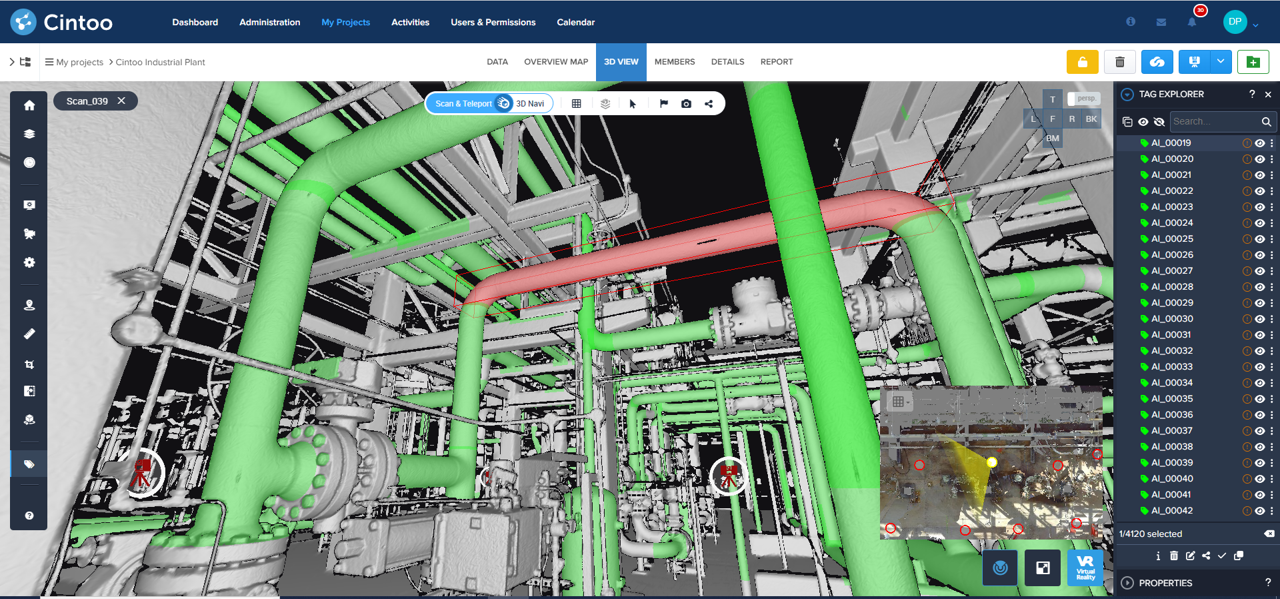

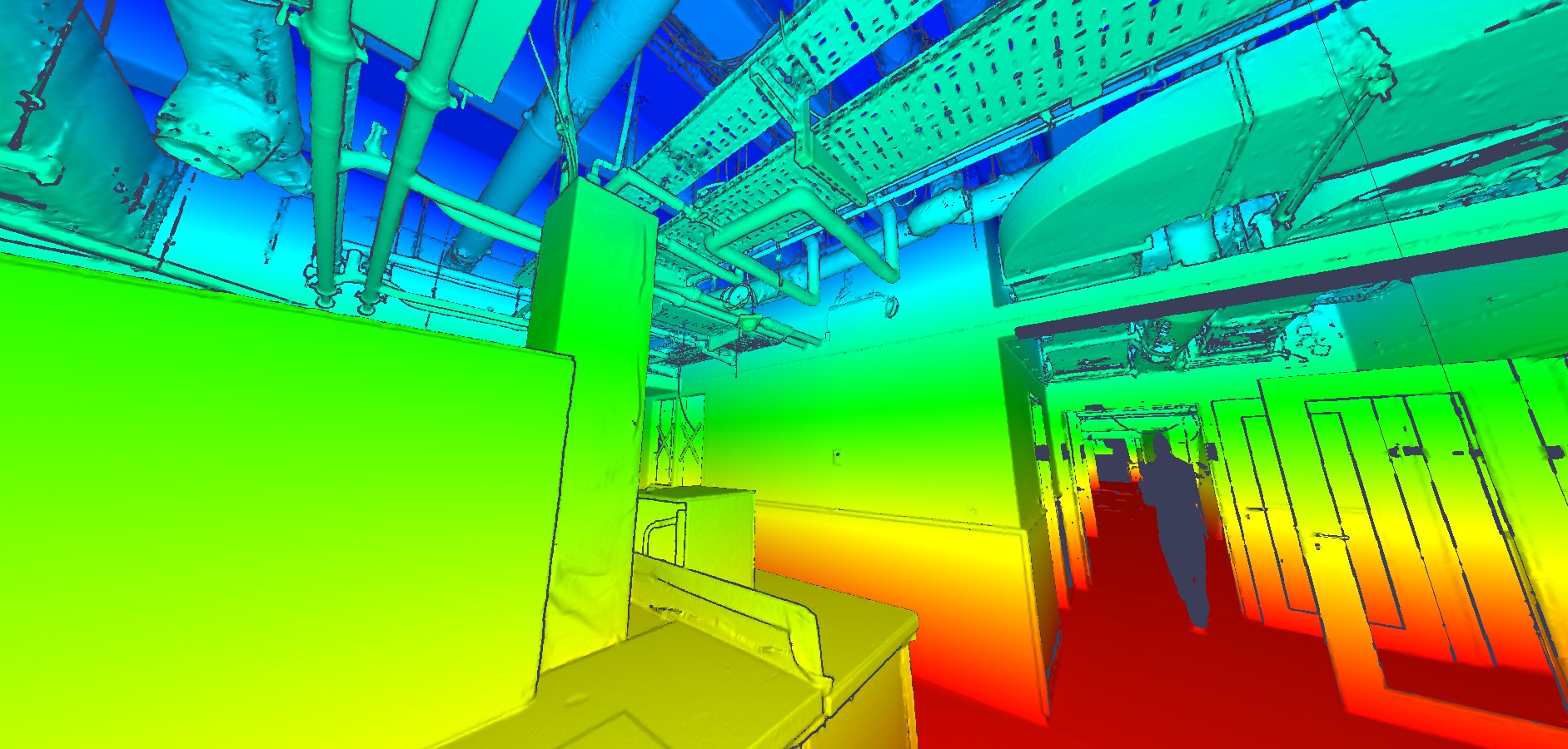

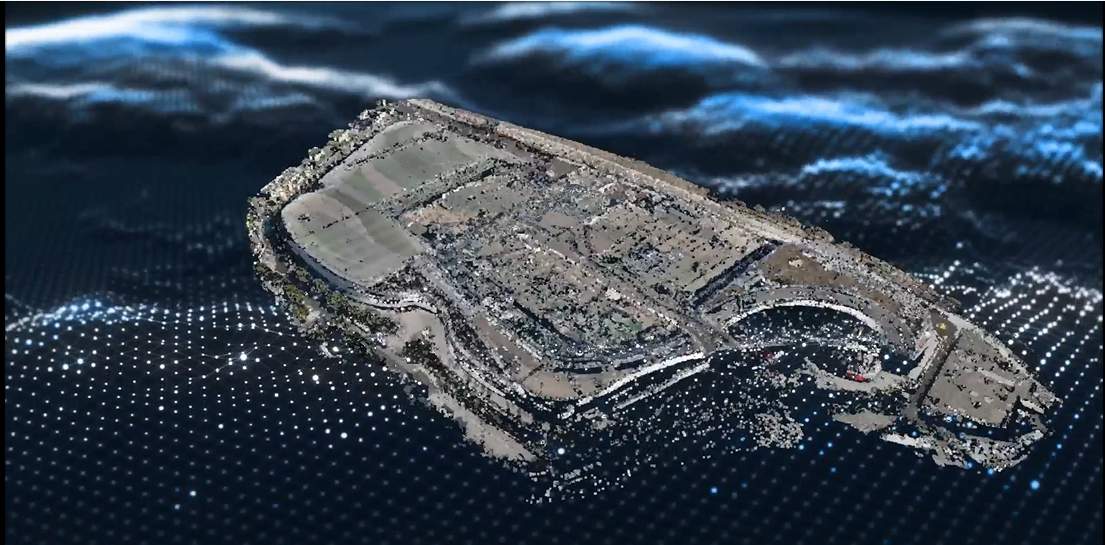

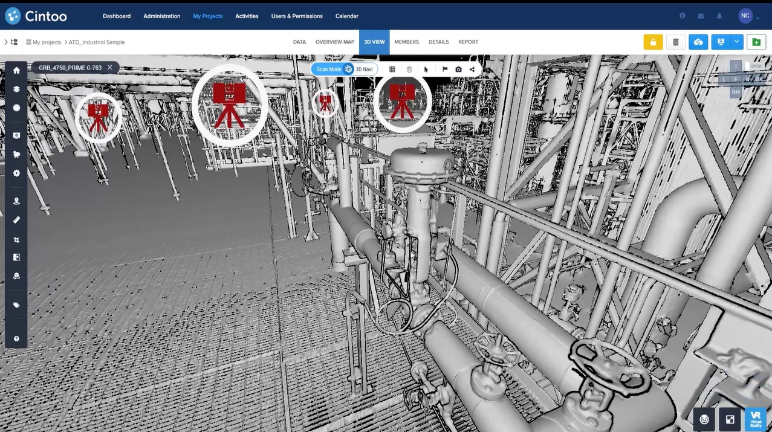

Visual twins are built from point cloud data generated by LiDAR devices- think terrestrial, mobile, or drone scanners. Laser scanners are, for the most part, becoming more accessible, especially mobile and drone ones that offer unique paths forward for collecting point cloud data in a variety of ways. But the next step of conversion is needed to level-up your design and build processes. Cintoo allows you to convert and view your scan data through your visual twin — all with an emphasis on creating a high-quality visual twin that makes workflows more accessible and more powerful. Benefits become clearer: navigation is easy, vantage points are endless, and different tools allow you to tag assets, crop areas, compare conditions, sync to BIM models, make automatic measurements, leave annotations, and more.

All of these capabilities in Cintoo allow you to easily perform updates, monitor maintenance, and manage resource-intensive sites, so much so that utilizing point cloud data now seems like the most obvious way forward to present a deliverable standard that promises the same benefits, including cost and time savings, and increased collaboration.

It’s what John from GM is doing. John’s team is actively using point cloud data for every single team member, no matter where they are in the world. Even more, they’re using point cloud data to converse over the whole industry, including with their suppliers, engineers, contractors, other third parties, and project managers to coordinate projects, make updates, and communicate effectively. “What this has done for us is it gives suppliers the flexibility to reach in and grab data as they need it. Just giving them that flexibility has really streamlined their approach to how they’re estimating, engineering and installing things in our facilities,” John explains.

When we make point cloud data the deliverable standard and it’s housed in a platform like Cintoo, the process becomes accessible and easy to understand for everyone involved. Attaining point cloud data and housing it in Cintoo not only saves time and money but ensures a quality workflow that gets rid of all the complexity!

This is the new deliverable standard taking shape today. Visit cintoo.com/customer-story to read the rest of GM’s Cintoo user story.