As energy infrastructure becomes increasingly complex and expansive, companies are constantly seeking innovative methods to enhance monitoring and maintenance operations. One such transformative technology is LiDAR scanner data processing, which consists of light detection and ranging to generate point cloud data. By offering highly accurate spatial data, LiDAR is revolutionizing the way energy companies use terrain models to manage pipelines, facilities, and terminals. Notably, BP has adopted LiDAR scanner data processing to optimize their infrastructure maintenance, reduce costs, and improve safety. This blog explores the profound impact of LiDAR scanner data processing on energy infrastructure monitoring and showcases how forward-thinking companies like BP are driving these advancements.

LiDAR (Light Detection and Ranging) is a remote sensing technology that uses laser light to measure distances and generate highly accurate 3D models of objects and environments based off of geospatial data. By capturing millions of point cloud data points in seconds, LiDAR creates "point clouds"—detailed digital representations of physical spaces. LiDAR scanner data processing involves transforming this raw point cloud data, mainly based on ground control points, into actionable insights through specialized software. This processed data is vital for infrastructure monitoring, as it enables accurate mapping, modeling, and analysis.

Energy infrastructure consists of asset-intensive facilities, pipelines and storage terminals, covering a huge swath of ground surface area. Such large and complex sites require ongoing monitoring to ensure operational efficiency and safety. Traditionally, physical site visits and manual inspections were the norm. However, these methods are often costly, time-consuming, and risky due to the numerous safety hazards on site versus digitally. Here’s where LiDAR scanner data processing comes into play.

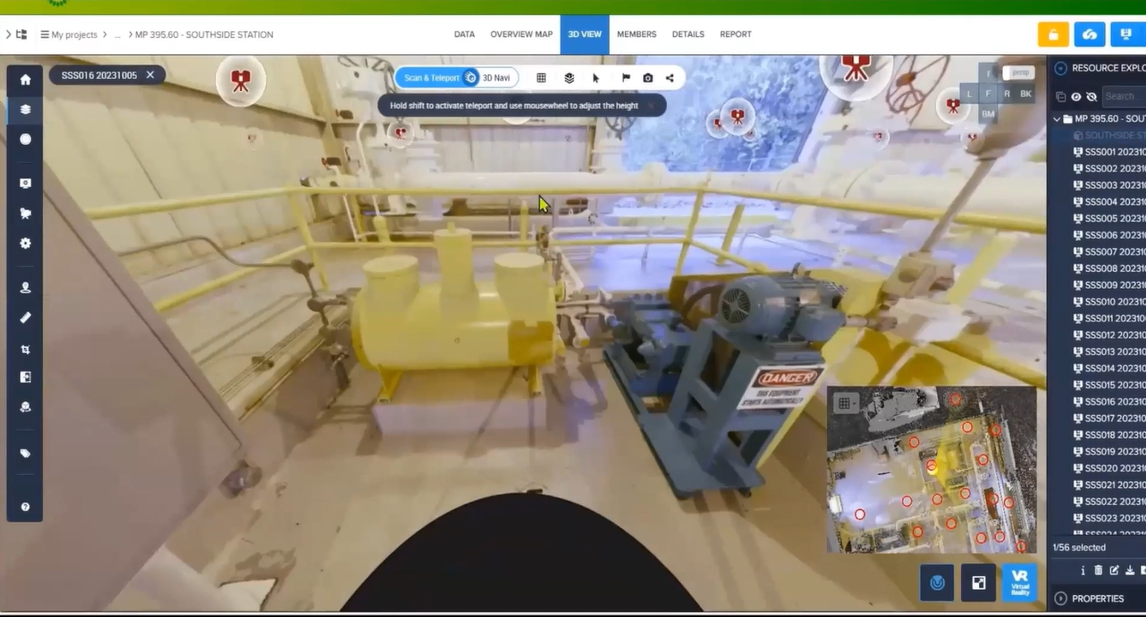

One of the standout benefits of using LiDAR scanner data processing in energy infrastructure is enabling virtual site visits. Rather than deploying teams to physically inspect remote or hazardous sites, companies can now use digital twins—virtual replicas of physical infrastructure created using lidar light detection, identifying objects of interest, and leading to more processed lidar data to revolve around a whole site configuration.

As Jeff Judycki, BP’s Documents and Records Team Lead, noted in a recent webinar with Cintoo, “At the beginning of this journey, I never imagined it would be possible to enable our organization to virtually visit a site."

Scan data is processed in Cintoo to create a rich virtual environment.

By processing LiDAR scanner data, BP can answer critical engineering and business questions from a virtual setting. This significantly reduces the need for travel, which is not only a high-risk activity but also contributes to carbon emissions.

Energy facilities undergo frequent modifications and upgrades, and keeping facility records up to date is often challenging. LiDAR scanner data processing provides highly accurate as-built documentation by capturing 3D scans of facilities post-construction. This ensures that teams always have access to up-to-date digital representations of their assets and that they are cementing the highest precision of data accuracy.

At BP, this approach eliminated a significant backlog of outdated facility updates: "Today, we have eliminated the submittal backlog and have kept up with ongoing submittals by coordinating as-built laser scanning with our vendors," Judycki explained.

By replacing outdated redline data and 2D drawings with comprehensive 3D models, BP enhanced the accuracy and reliability of their facility documentation.

Insert up to date 3D models in Cintoo for better visualization.

LiDAR scanner data processing plays a critical role in design validation and collaboration. Using platforms like Cintoo, which integrates with LiDAR data, stakeholders can virtually review designs and verify measurements, based off the terrain model, before construction begins.

BP successfully rendered their processed lidar data in Cintoo as Cintoo facilitates visualization of cumbersome data. With Cintoo, Judycki’s team was also able to find a solution that promoted collaboration through a central, virtual setting, meaning multiple different team members and stakeholders, regardless of their location, could have oversight on the project. Most importantly, BP was able to utilize the full potential of their lidar point clouds in Cintoo by using Cintoo’s intuitive tool sets. This includes being able to verify equipment replacements remotely, avoiding costly redesigns, taking automatic measurements, annotating, and tracking progress. Judycki notes that, "In one case, we saved $10,000 on an in-line replacement for a flow meter by verifying dimensions of the existing equipment and ensuring the new meter would fit."

By catching potential issues before construction begins, companies avoid costly downtime and on-site labor expenses. Considering that daily labor costs for redesigns can exceed $15,000, the savings are substantial.

Another key application of LiDAR scanner data processing is asset inspection. By combining ground control points with high-resolution imagery, companies can visually inspect infrastructure components like piping systems, valves, and structural elements.

BP is now leveraging this workflow to transition from schematic Piping and Instrumentation Diagrams (P&IDs) to point cloud data for corrosion monitoring, also capable in the Cintoo platform. Judycki elaborated on the future impact of LiDAR on BP’s inspection programs: "We are working to develop consistent inspection segments and track corrosion progress. The ability to visually inspect these assets remotely in Cintoo is a game-changer for safety and efficiency."

By generating point clouds with LiDAR scanner data, inspections are not only more accurate but also less disruptive to ongoing operations. Even more, using an array of lidar technology to facilitate lidar data processing in a centralized platform like Cintoo offers use cases that go above and beyond project expectations.

Sustainability is at the forefront of energy companies’ priorities. By reducing physical site visits, LiDAR scanner data processing directly supports carbon reduction initiatives. Virtual inspections and remote collaborations cut down on travel, lowering emissions while improving productivity.

BP’s approach aligns seamlessly with their sustainability goals as "reduced travel has a positive environmental impact, helping us meet our goal of net zero by 2050 or sooner," Judycki emphasized.

This benefit highlights how digital solutions like LiDAR scanner data processing can simultaneously enhance operational efficiency and environmental responsibility.

Despite its benefits, implementing processed lidar in energy infrastructure monitoring comes with challenges. BP’s Chris Anderson, who has championed lidar technology’s adoption, explained their early hurdles: "When we started defining how we wanted to improve our facility information, the scope of the challenge seemed daunting. We had technical and logistical questions on where to focus our efforts first."

By adopting a phased, programmatic approach in using Cintoo as their all-in-one platform, BP successfully navigated these challenges. They prioritized key facilities, implemented robust data processing workflows, and ensured that all stakeholders—from engineers to third-party vendors—had access to processed LiDAR data in Cintoo with no complexity or difficulty.

The adoption of LiDAR scanner data processing is revolutionizing energy infrastructure monitoring. By enhancing accuracy, enabling virtual site visits at a high resolution, and supporting collaborative design processes, LiDAR point clouds empower energy companies to operate more efficiently, safely, and sustainably.

BP’s success demonstrates how leveraging LiDAR scanner data processing can address key operational challenges, reduce costs, and drive innovation. As the energy sector continues to evolve, this technology will play an increasingly vital role in ensuring that critical infrastructure remains safe, efficient, and well-maintained. However, LiDAR data needs to be processed in order to have full potential.

Cintoo provides the solution for energy companies to quickly and easily process their lidar point clouds, producing actionable and insightful workflows. Cintoo gives control to team members and project managers to be able to visualize their total energy infrastructure in one centralized platform so it is at the same high resolution as the lidar sensor. This means no compromise to accuracy and no difficulties when sharing access.

To make the most out of your LiDAR scanner data processes, and to start monitoring energy infrastructure smarter, safer, and in a more sustainable way, read more about how Cintoo can level up your energy workflows for better project coordination and ROI benefits.

Discover the five ways digital twins can be optimized for energy facility maintenance.