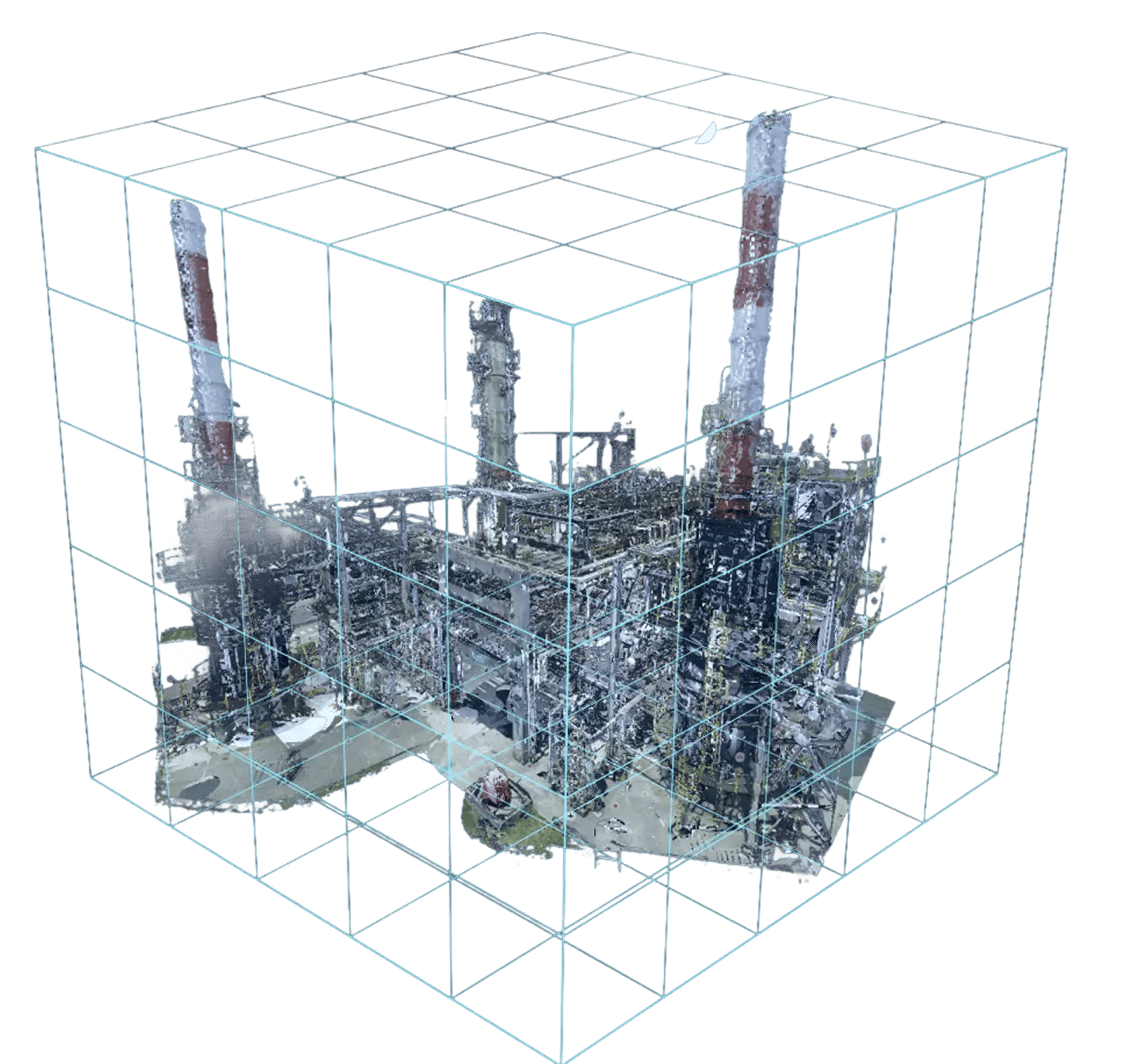

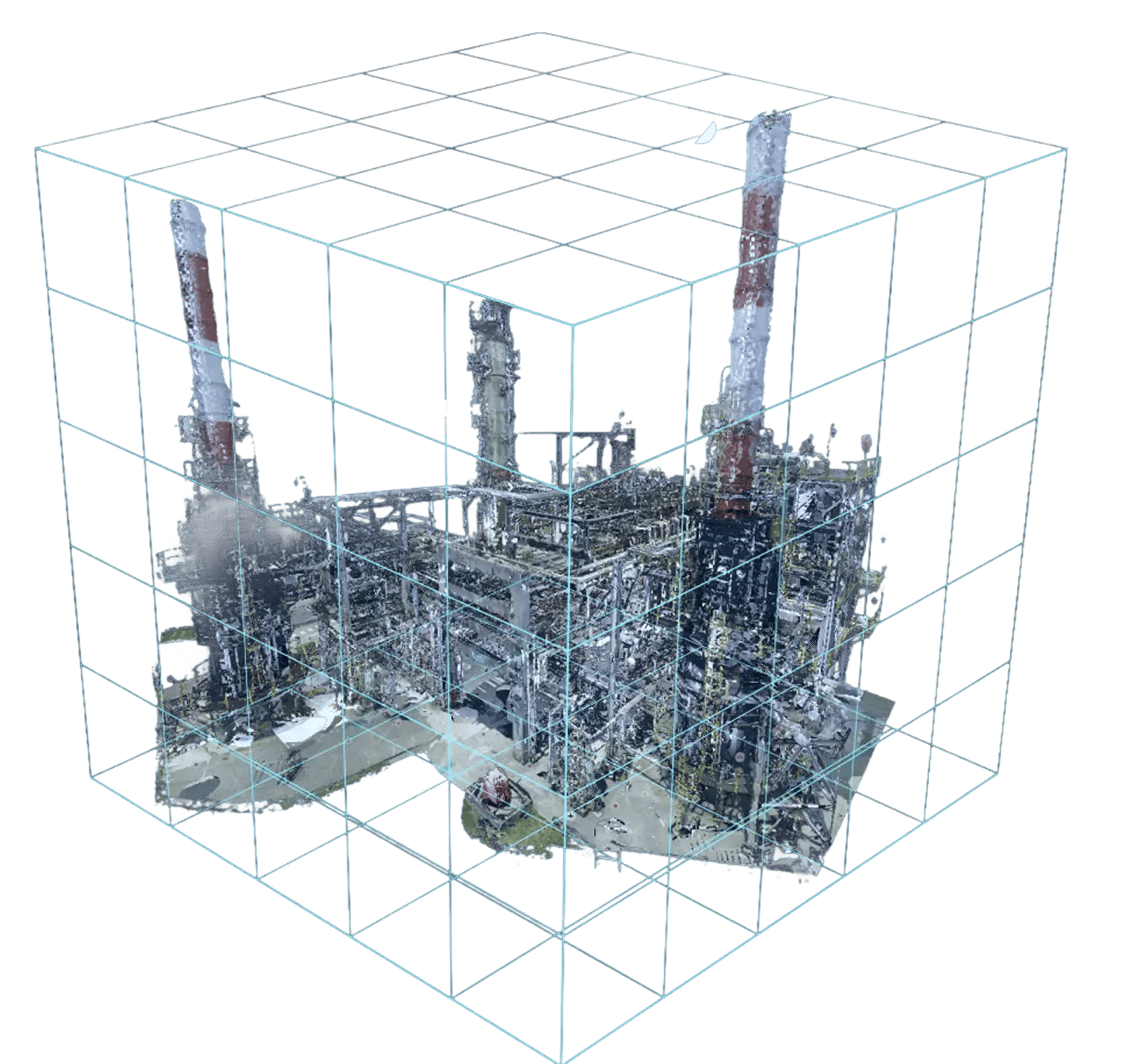

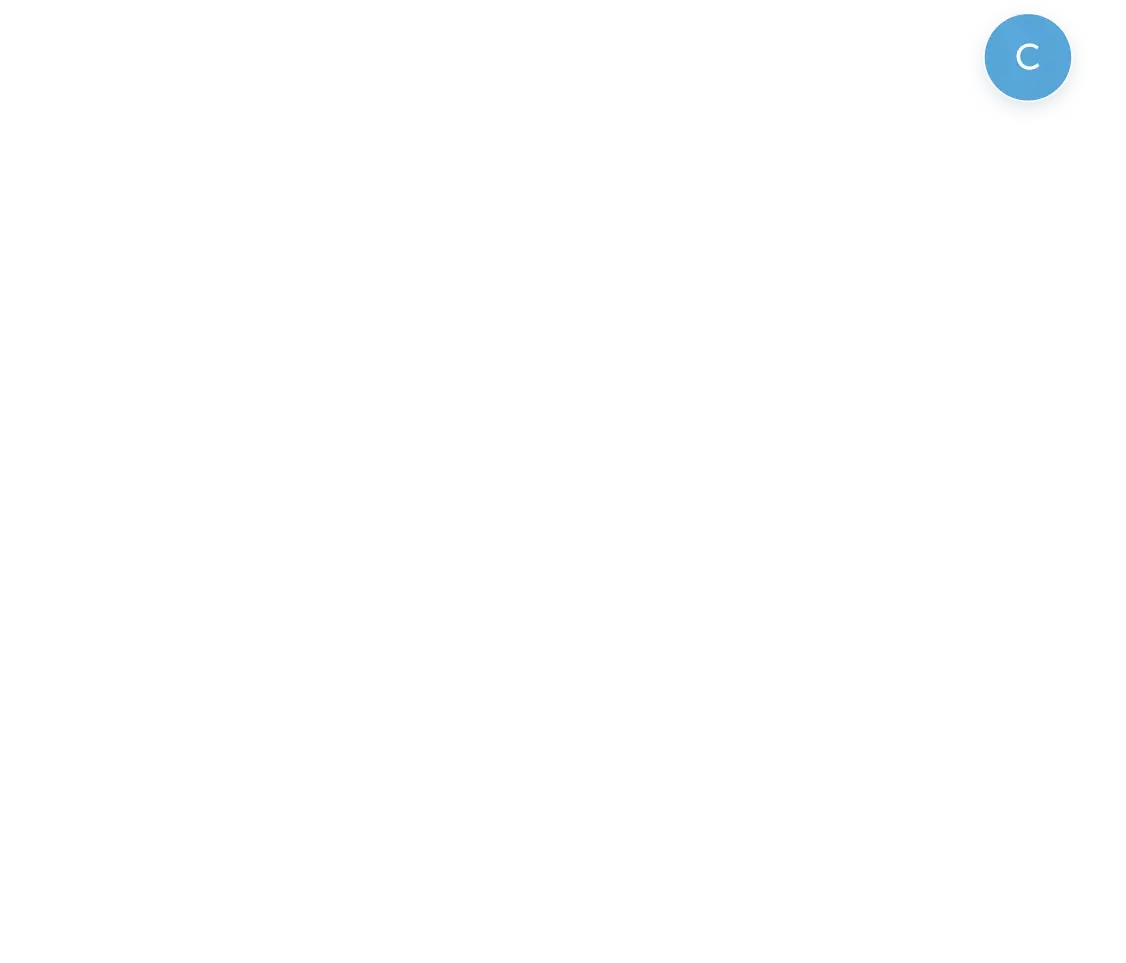

Streamline asset visualization with cloud-native workflows. Unify 3D scan data to create a single source of visual truth and leverage your Digital Twin for brownfield projects.

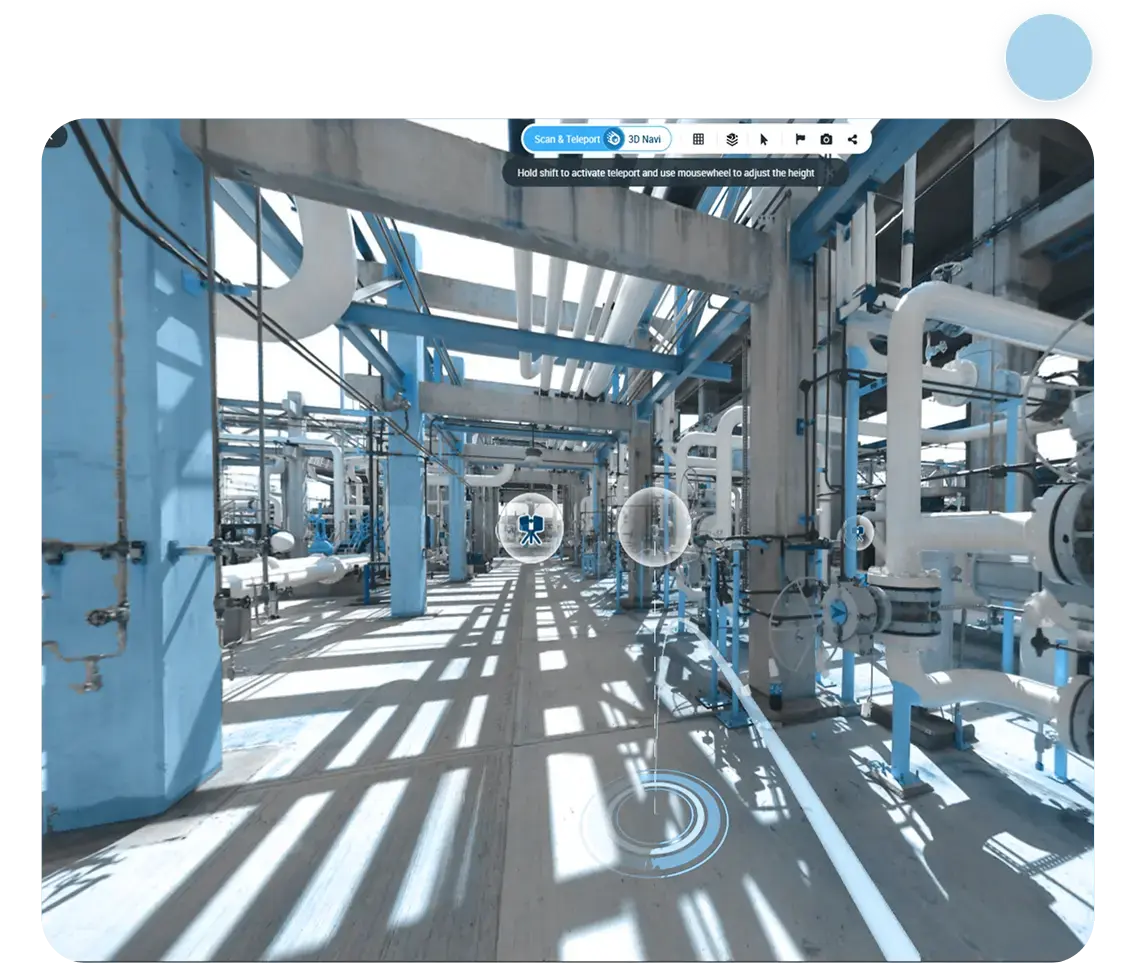

Easy, remote access to accurate, up-to-date 3D data, enabling efficient maintenance planning. The results are better asset oversight and reduced operational downtime.

Gain seamless access to high-quality, scan-based digital twins, streamlining design based on real-world conditions without the need to handle massive raw scan files.

Power facility maintenance through remote inspections and asset monitoring. Reduce onsite visits and downtime, keep track of repairs, and operate on connected metadata.

Organize, track, and manage your physical assets in context.

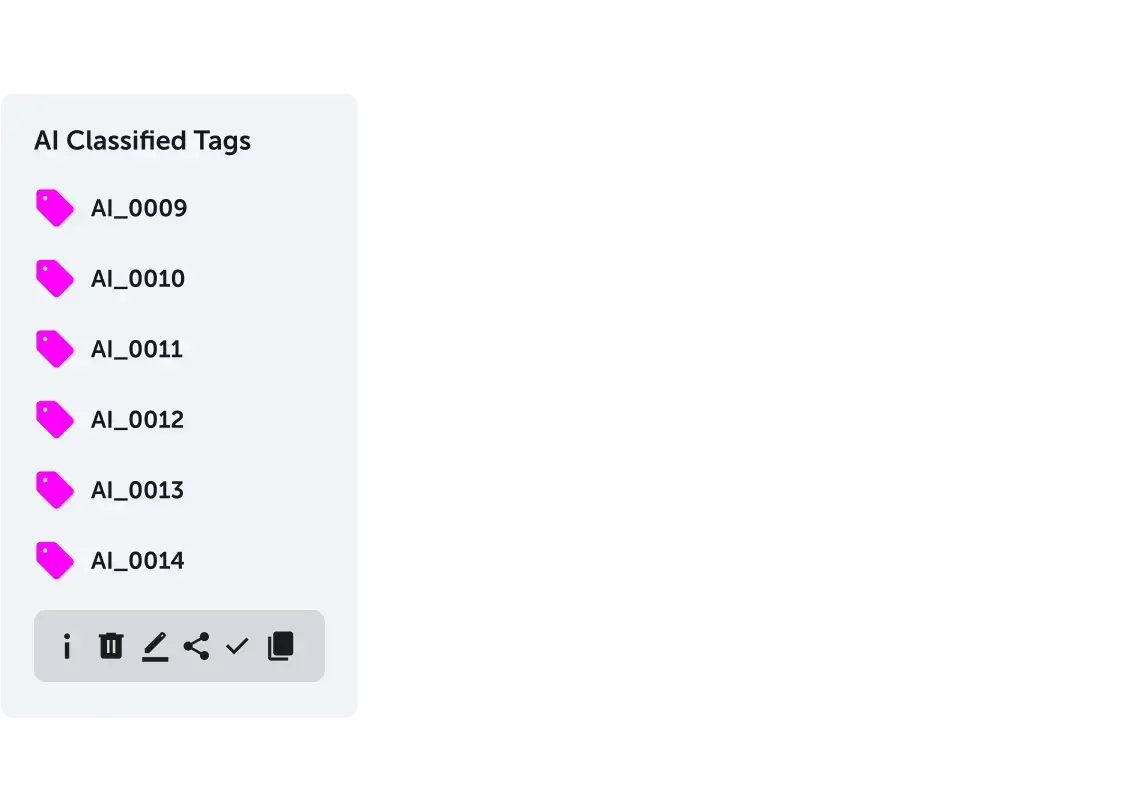

Automatically identify and categorize objects in your scan data using AI.

Attach and manage custom metadata to objects and areas within the 3D environment.

Connect scan data to live IoT sensors or asset management platforms to unify real-time data.

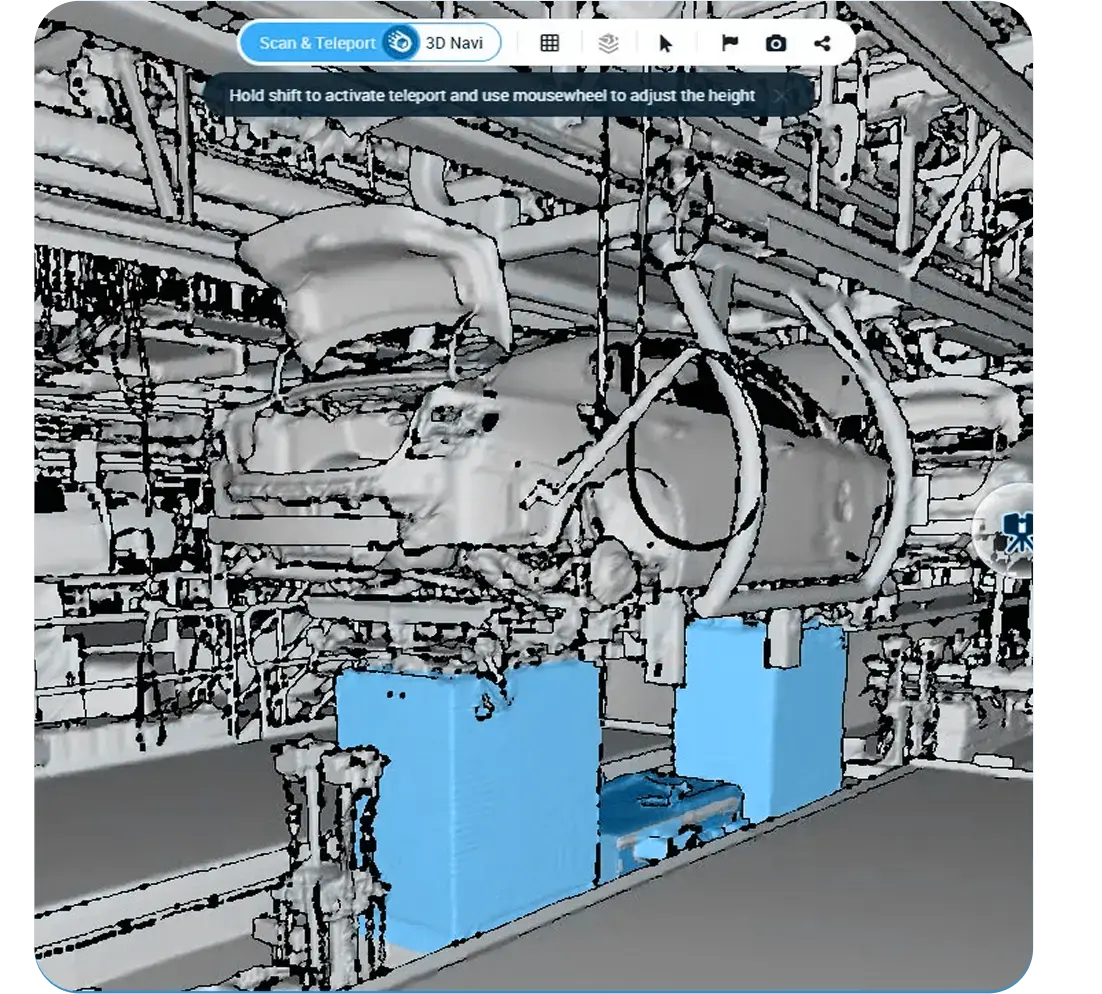

Visualize complex facilities in the cloud, enabling remote teams to inspect, measure, and collaborate.

Maintain a single source of truth, accessible throughout the project lifecycle.

Gain access to a single source of visual truth—anytime, anywhere. Teams can contextualize as-built conditions to streamline facility management, reduce site visits, enable remote inspections, and support virtual walkthroughs. Strengthen your digitalization strategy with a secure, scalable cloud solution.

Navigate and inspect high-resolution digital twins of facilities, enabling quick verification of equipment, layout, and conditions. AI-powered object classification and custom tagging allows you to organize assets spatially and semantically—making it easy to search, group, and maintain components.

Connect your interactive 3D environment with key enterprise systems like ERP, MES, CMMS, and IoT to enrich your asset data with live, contextual insights. Link your systems of record directly to physical assets and facility areas in the 3D scan data, creating a unified view of operations, maintenance, and performance.

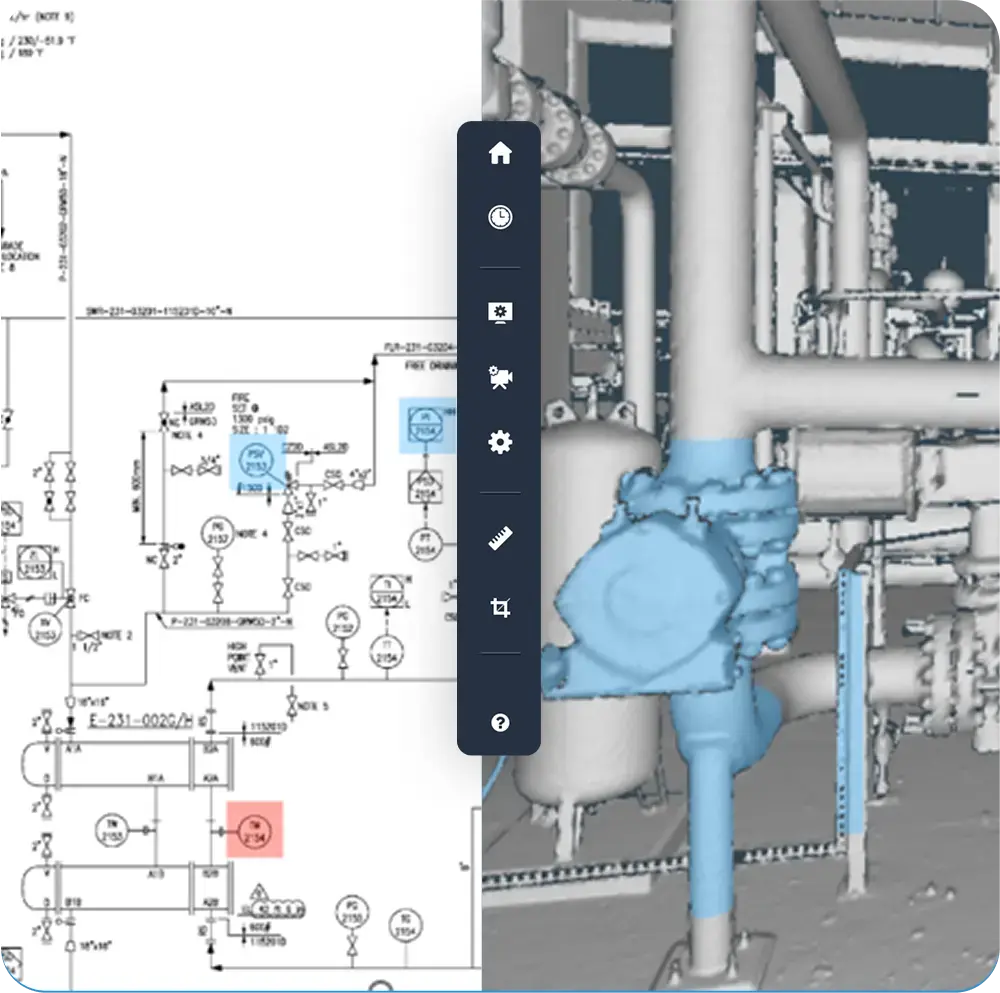

Cintoo eliminates guesswork, streamlines navigation, and enables faster, and more accurate P&IDs overall. Import blueprint datasets such as PDF or TIFF drawings directly into the platform, where they are embedded in a P&ID viewer alongside the 3D environment. This allows teams to quickly locate instrumentation and equipment through defined rectangles, trace piping with polylines, and visually align these elements.

Extropic Energy Inc. leverages Cintoo for enhanced asset visualization and streamlined operations, enabling upstream and midstream energy owners to reduce site visits by up to 50% and cut unplanned downtime by 10–15%. By improving design coordination and supporting clash detection, Cintoo helps lower project rework and schedule delays by 20–30%.

Cintoo allows us to easily confirm that what we are modeling is accurate. There’s no other real solution on the market that is doing the same thing.

Cintoo takes the survey a step further, offering intuitive ways to interact with scan data, as a tool for building P&IDs with accuracy and confidence. For process sites, compliance, maintenance, and asset management are crucial and Cintoo allows us to track all of it virtually.

The data is big from our sites, and we needed to be able to upload it to the cloud so that everyone could access that data, download it, measure and manipulate with it. We were able to do that with Cintoo.

Dedicated help and support at any stage of the project lifecycle.

Compliant with the highest standards of data protection.

GDPR compliancy means your 3D scan data is handled with the highest standards of privacy.

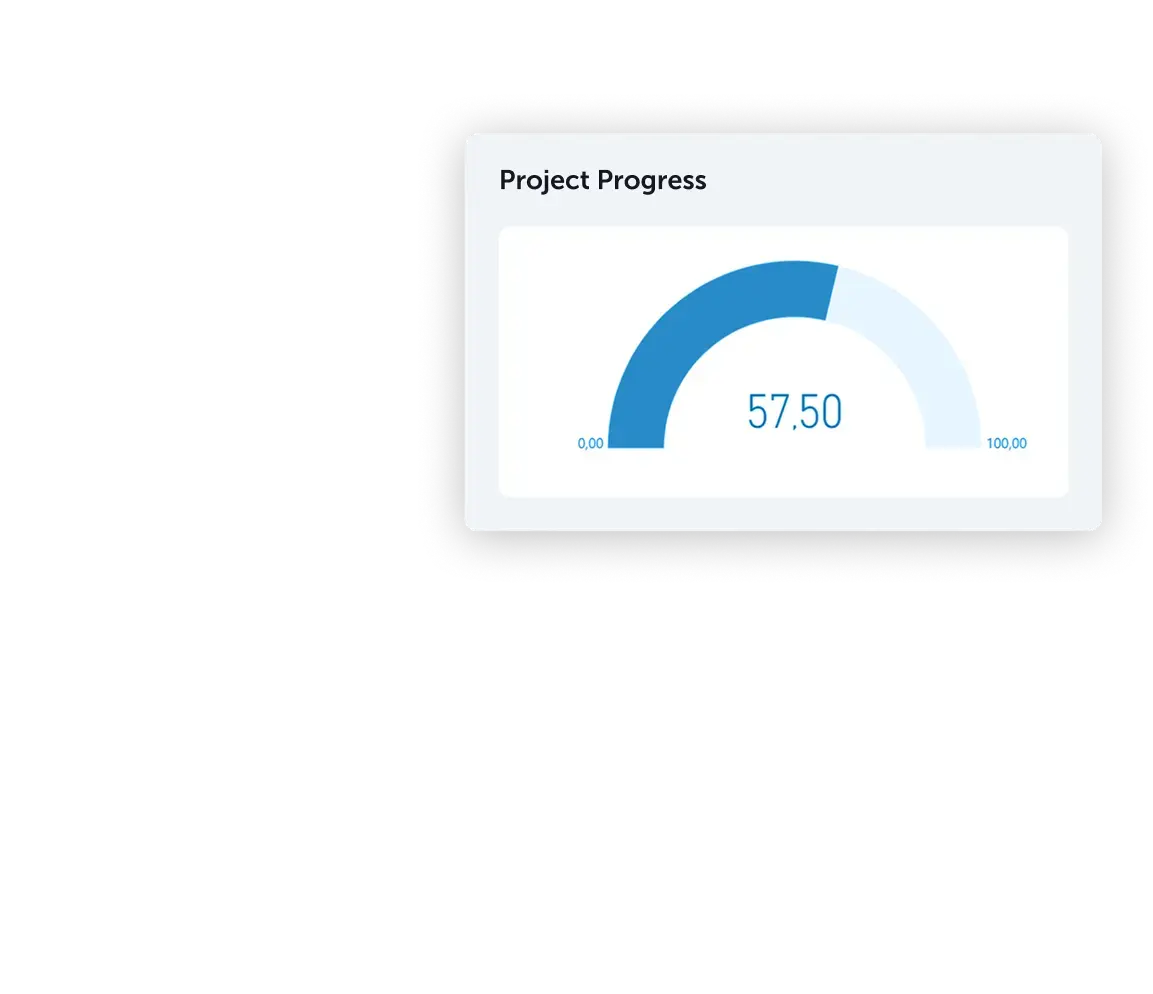

BIM Edition focuses on construction phase workflows like scan-to-BIM comparison and progress tracking, while Twin Edition is designed for ongoing asset and facility management in industrial environments. Essentially, BIM Edition supports design verification during building, and Twin Edition supports asset oversight throughout operations.

Asset Tagging lets you attach digital labels, notes, or metadata directly to specific parts of your digital twin—such as equipment, piping, or machinery—making it easier to identify, track, and manage individual assets within large industrial facilities.

Cintoo Twin Edition provides intuitive web-based tools that allow users to create, customize, and place asset tags directly within the 3D digital twin environment. These tools include point-and-click tagging, metadata input forms, and AI-powered detection and classification tools.

Yes. You can upload and compare scans captured at different dates to identify changes, detect asset deterioration, and verify completed maintenance work.

By providing precise location-based tagging within the digital twin, teams can quickly locate assets, understand their condition, and plan maintenance activities more efficiently—reducing downtime and avoiding costly errors.

Explore Industry Solutions Today.