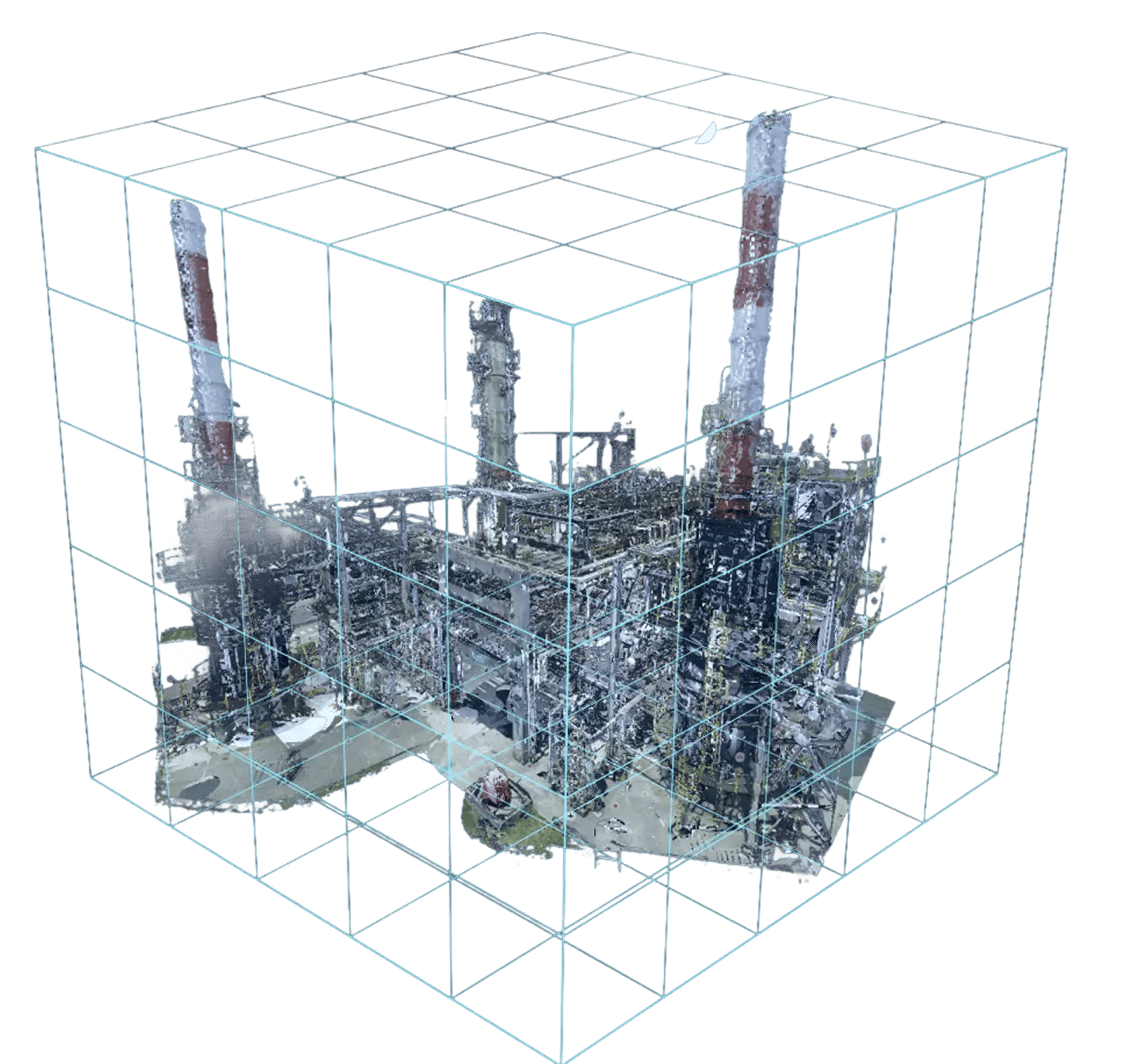

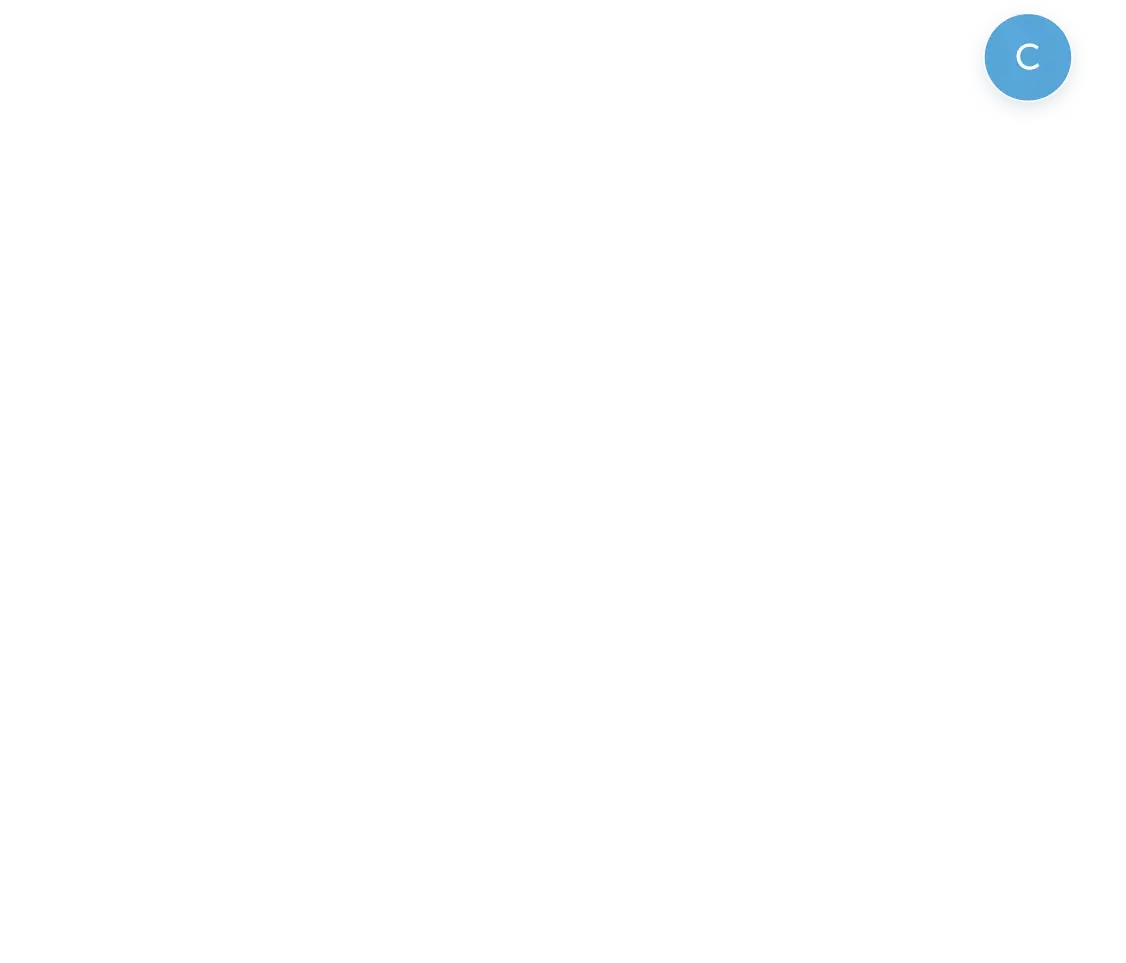

Semplificate la visualizzazione degli asset con flussi di lavoro cloud-native. Unificate i dati di scansione 3D per creare un'unica fonte di verità visiva e sfruttate il vostro gemello digitale per i progetti brownfield.

Accesso facile e remoto a dati 3D accurati e aggiornati, per una pianificazione efficiente della manutenzione. Il risultato è una migliore supervisione degli asset e una riduzione dei tempi di inattività operativa.

Ottenete un accesso continuo a gemelli digitali di alta qualità basati su scansioni, semplificando la progettazione basata su condizioni reali senza dover gestire enormi file di scansione grezzi.

Potenziate la manutenzione delle strutture attraverso ispezioni e monitoraggio degli asset in remoto. Riducete le visite in loco e i tempi di inattività, tenete traccia delle riparazioni e operate sui metadati collegati.

Organizzate, tracciate e gestite i vostri beni fisici in modo contestuale.

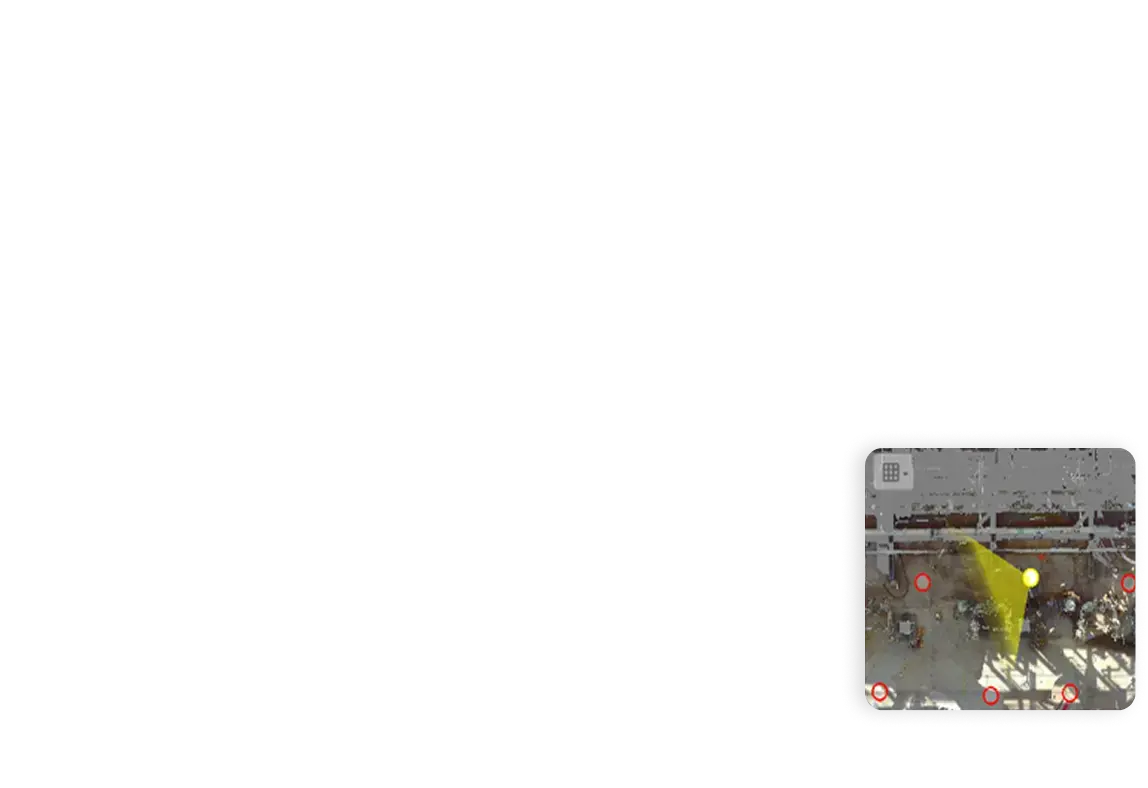

Identificazione e categorizzazione automatica degli oggetti nei dati di scansione grazie all'intelligenza artificiale.

Allegare e gestire metadati personalizzati agli oggetti e alle aree dell'ambiente 3D.

Collegate i dati di scansione ai sensori IoT o alle piattaforme di gestione degli asset per unificare i dati in tempo reale.

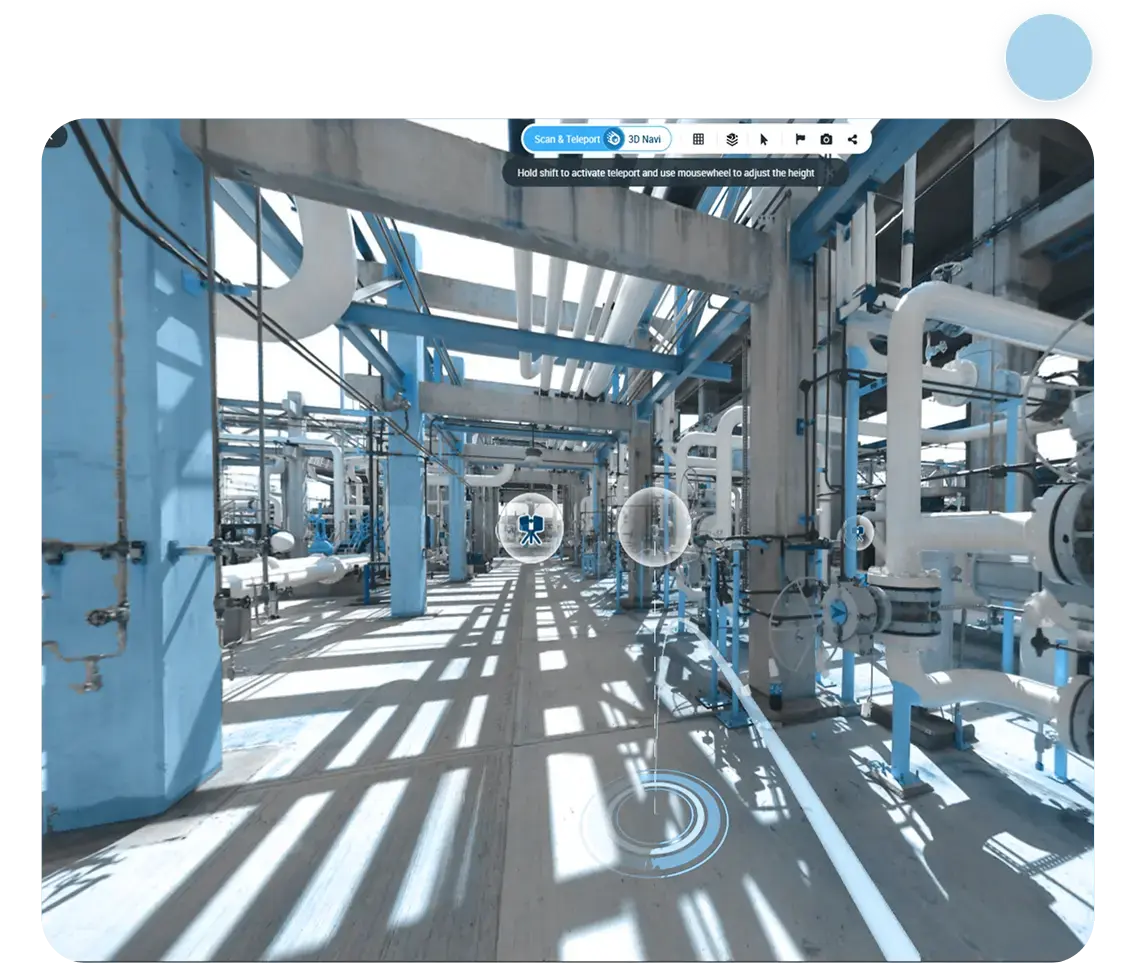

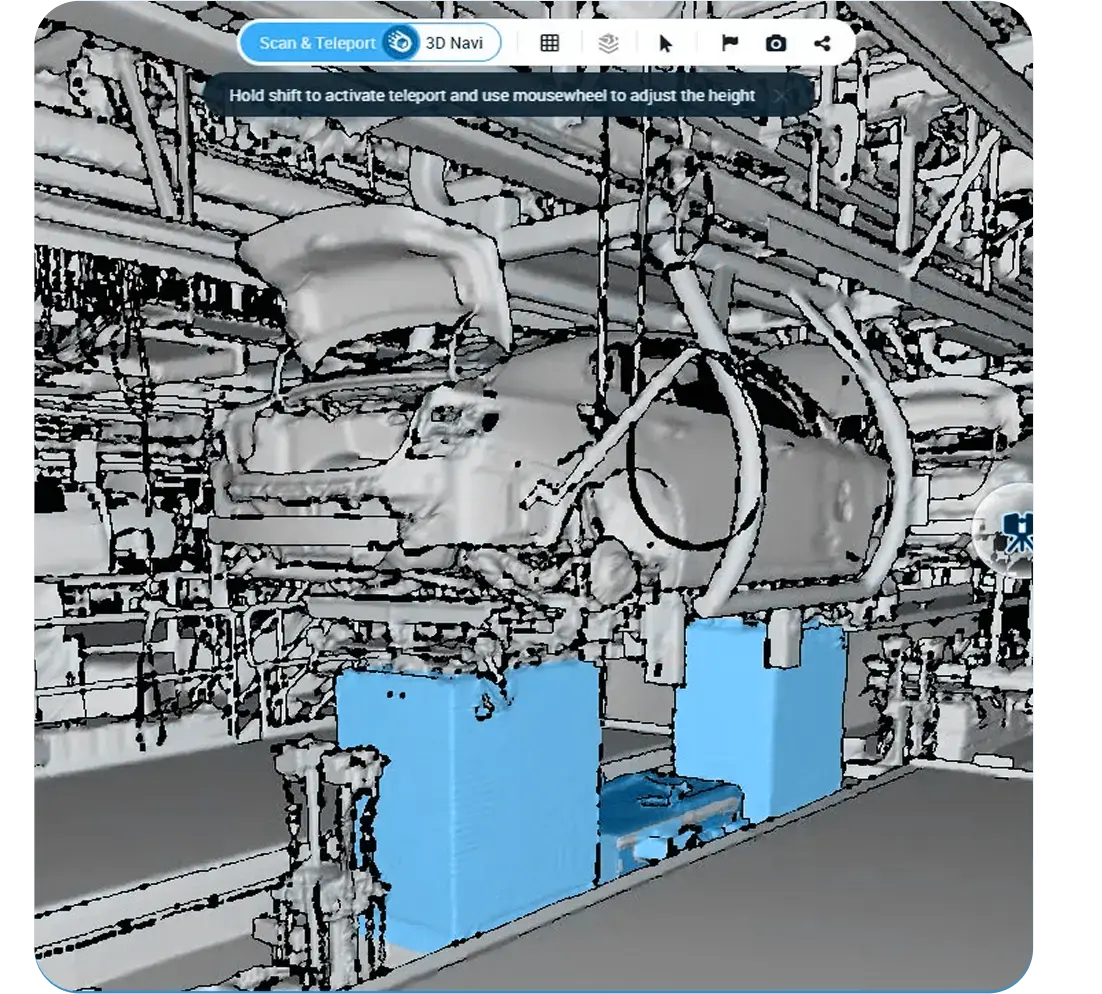

Visualizzate strutture complesse nel cloud, consentendo ai team remoti di ispezionare, misurare e collaborare.

Mantenere un'unica fonte di verità, accessibile durante tutto il ciclo di vita del progetto.

Ottenete l'accesso a un'unica fonte di verità visiva, sempre e ovunque. I team possono contestualizzare le condizioni di costruzione per semplificare la gestione delle strutture, ridurre le visite in cantiere, consentire ispezioni remote e supportare le visite virtuali. Rafforzate la vostra strategia di digitalizzazione con una soluzione cloud sicura e scalabile.

Navigate e ispezionate i gemelli digitali ad alta risoluzione delle strutture, consentendo una rapida verifica delle attrezzature, del layout e delle condizioni. La classificazione degli oggetti e l'etichettatura personalizzata, basate sull'intelligenza artificiale, consentono di organizzare le risorse in modo spaziale e semantico, facilitando la ricerca, il raggruppamento e la manutenzione dei componenti.

Collegate l'ambiente 3D interattivo con i principali sistemi aziendali come ERP, MES, CMMS e IoT per arricchire i dati sugli asset con informazioni contestuali in tempo reale. Collegate i vostri sistemi di registrazione direttamente agli asset fisici e alle aree della struttura nei dati della scansione 3D, creando una visione unificata di operazioni, manutenzione e prestazioni.

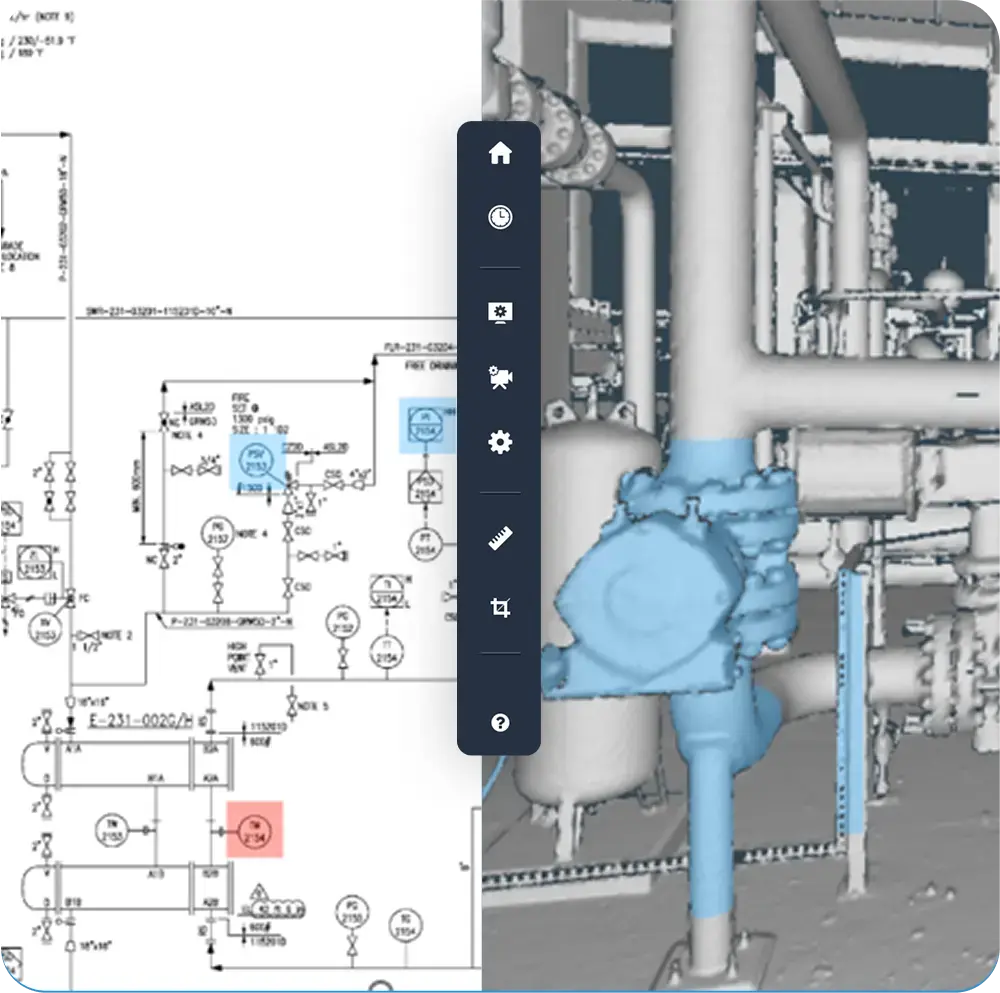

Cintoo elimina le congetture, semplifica la navigazione e consente di realizzare P&ID più rapidi e accurati. L'importazione di dati blueprint, come disegni PDF o TIFF, avviene direttamente nella piattaforma, dove vengono incorporati in un visualizzatore P&ID accanto all'ambiente 3D. In questo modo i team possono individuare rapidamente la strumentazione e le apparecchiature attraverso rettangoli definiti, tracciare le tubazioni con polilinee e allineare visivamente questi elementi.

Extropic Energy Inc. utilizza Cintoo per migliorare la visualizzazione degli asset e semplificare le operazioni, consentendo ai proprietari di impianti energetici a monte e a medio raggio di ridurre le visite in loco fino al 50% e di tagliare i tempi di inattività non pianificati del 10-15%. Migliorando il coordinamento della progettazione e supportando il rilevamento degli scontri, Cintoo contribuisce a ridurre le rielaborazioni dei progetti e i ritardi nella programmazione del 20-30%.

Cintoo ci permette di confermare facilmente che ciò che stiamo modellando è accurato. Non esiste un'altra soluzionereale sul mercato che faccia la stessa cosa.

Cintoo fa un ulteriore passo avanti nell'indagine, offrendo modi intuitivi per interagire con i dati di scansione , come strumento per costruire P&ID con precisione e sicurezza. Per i siti di processo, la conformità, la manutenzione e la gestione delle risorse sono fondamentali e Cintoo ci permette di tenere traccia di tutto ciò in modo virtuale.

I dati provenienti dai nostri siti sono molto grandi e dovevamo essere in grado di caricarli sul cloud in modo che tutti potessero accedervi, scaricarli, misurarli e manipolarli. Con Cintoo siamo riusciti a farlo.

Assistenza e supporto dedicati in qualsiasi fase del ciclo di vita del progetto.

Conforme ai più elevati standard di protezione dei dati.

La conformità al GDPR significa che i vostri dati di scansione 3D sono trattati con i più alti standard di privacy.

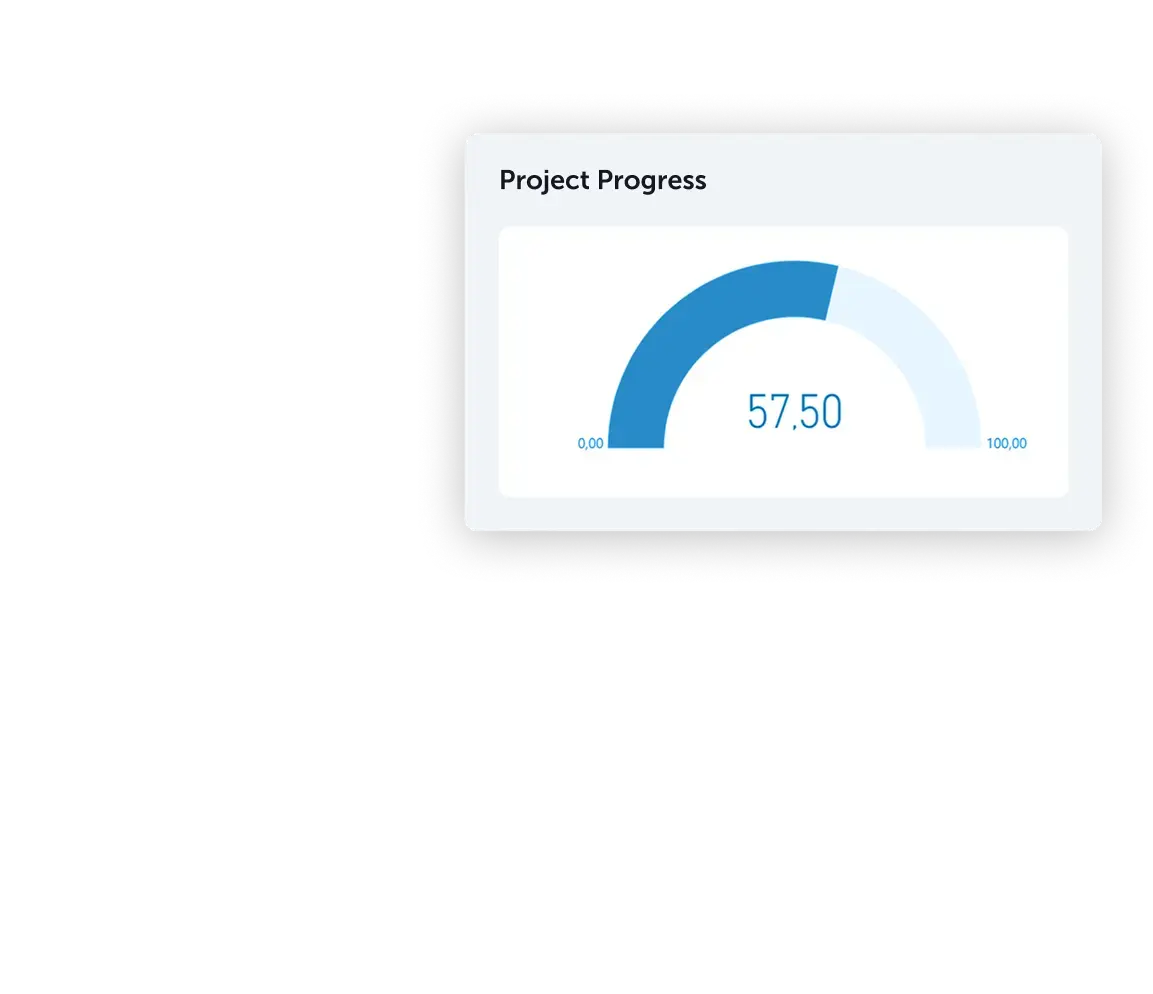

La BIM Edition si concentra sui flussi di lavoro della fase di costruzione, come il confronto tra scansioni e BIM e il monitoraggio dell'avanzamento dei lavori, mentre la Twin Edition è progettata per la gestione continua degli asset e delle strutture negli ambienti industriali. In sostanza, la BIM Edition supporta la verifica del progetto durante la costruzione, mentre la Twin Edition supporta la supervisione degli asset durante l'esercizio.

L'Asset Tagging consente di applicare etichette digitali, note o metadati direttamente a parti specifiche del gemello digitale, come apparecchiature, tubazioni o macchinari, facilitando l'identificazione, la tracciabilità e la gestione dei singoli asset all'interno di grandi impianti industriali.

Cintoo Twin Edition offre strumenti intuitivi basati sul web che consentono agli utenti di creare, personalizzare e posizionare le etichette degli asset direttamente nell'ambiente del gemello digitale 3D. Questi strumenti comprendono l'etichettatura point-and-click, i moduli di inserimento dei metadati e gli strumenti di rilevamento e classificazione basati sull'intelligenza artificiale.

Sì. È possibile caricare e confrontare scansioni acquisite in date diverse per identificare i cambiamenti, rilevare il deterioramento degli asset e verificare gli interventi di manutenzione completati.

Fornendo un'etichettatura precisa basata sulla posizione all'interno del gemello digitale, i team possono localizzare rapidamente gli asset, comprenderne le condizioni e pianificare le attività di manutenzione in modo più efficiente, riducendo i tempi di fermo ed evitando errori costosi.

Esplorate oggi le soluzioni del settore.