Digital twins have become a hallmark of Industry 4.0 innovation. In essence, a digital twin is a dynamic digital model of a physical asset, system or process – updated with live data and used for analysis and decision-making. For example, a twin might be an exact virtual replica of a factory machine, a building, or even an entire plant. Connected sensors stream real-world data (like temperatures, pressures or motion) into the model, so engineers can see how the asset is performing now and predict how it will behave in the future. In this blog, we explain what a digital twin is, why its meaning varies by industry, why centralized data is critical, how adding IoT sensors and metadata makes twins live and accurate, and finally how open platforms support digital twin initiatives.

A digital twin is essentially a live, data-rich virtual version of a physical thing. It is a virtual representation of an object or system that spans its lifecycle, is updated from real-time data, and uses simulation, machine learning and reasoning to help decision-making. In other words, it mirrors the real item both in form and in function. It can also be thought of as a digital replica of a physical object, person, system, or process, contextualized in a digital version of its environment. In practice this means engineers build a 3D model (or series of models) of the asset and then continuously feed live data from sensors into it, giving it a real-time essence.

Digital twins allow organizations understand the present and predict the future. For example, IBM explains that a twin helps engineers see not only “how products are performing, but how they will perform in the future”. By analyzing live and historical data in the model, teams can troubleshoot remotely, run simulations, and optimize maintenance schedules. Digital twins have enabled use cases like testing new car designs in software before building prototypes, or monitoring factory equipment like a robotic arm on the fly to prevent failures. In each case, the twin acts as a “window” into the asset’s status – turning raw sensor feeds into a clear visual with actionable data attached to it.

The term digital twin is used in many sectors and carries different meanings. There is no single definition that fits all use cases. In manufacturing, a digital twin might be a model of a production line or robot, used for predictive maintenance and process optimization. In construction and facility management, it often refers to a 3D building model (like a BIM model) enriched with operational data for a building or plant. Utilities and energy companies use twins to mirror networks of equipment (for example, a digital copy of a substation or pipeline) to improve asset management and planning. Even in smart cities or infrastructure, a city-wide digital twin can map traffic flows or utilities.

Because of this range of uses, some analysts break digital twins into categories. McKinsey, for example, identifies product twins (models of individual products or components at various stages), data twins (like Google Maps being a twin of the Earth’s surface), systems twins (modeling entire factory or supply-chain processes), and infrastructure twins (virtual versions of buildings, roads or bridges). Across industries – from aerospace and automotive to oil & gas, manufacturing, and real estate – organizations use twins in ways tailored to their needs. In short, the underlying concept is the same, but the scope and focus of the twin can vary widely.

At its core, a digital twin depends on centralized, high-quality data. To be useful, a twin must gather and align data from every phase of an asset’s life: design, construction, commissioning, and operation. The digital twin's value comes from how it centralizes and contextualizes data for the asset's lifecycle, linking the as-built model with IT/OT data for a complete view. In practice, this means breaking down silos. For example, CAD drawings, sensor logs, and maintenance records normally live in different systems. A robust twin solution creates a “digital thread” that flows this data seamlessly from one stage to the next.

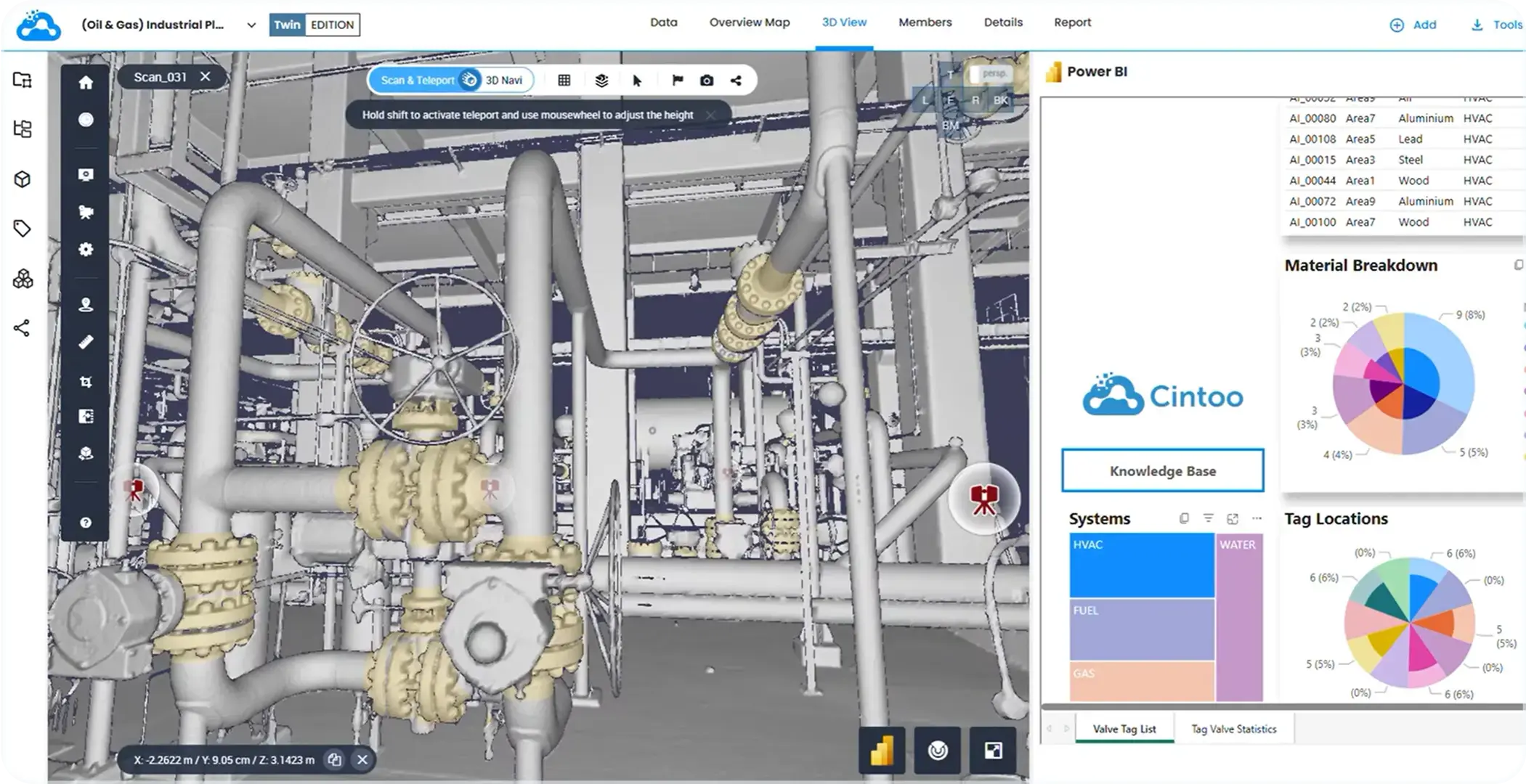

When all relevant data is assembled in one model, the twin becomes the single source of truth for the asset. Rather than separate spreadsheets or reports, the twin’s 3D model and data act as a dependable repository of accurate information. It becomes a single source of truth for users. In other words, centralized data makes the twin the authoritative reference for an asset’s state. Without good data coordination, however, a twin would be incomplete or out of date. That’s why organizations emphasize data integration up front. As one utility-industry study notes, “A digital twin needs all of these datasets to support modeling, analysis, and preventative maintenance. The data has to be centralized and it has to flow from design to manufacturing, construction, and operations to give users a holistic view. In summary, building an effective digital twin starts by aggregating the right data into a unified, well-structured model. For reality capture workflows, this means using a variety of scanners to collect data from the scope of the project and taking it one step further to upload and stream the data in an open, accessible web-based browser application like Cintoo. The aggregate data can then be assembled into one holistic view since Cintoo is agnostic, giving users a streamlined and total view of their site and site conditions, including relevant pieces of equipment/other critical assets.

The defining power of a modern digital twin comes from live data feeds. By connecting IoT sensors and other real-time inputs, the twin stays continually up-to-date. This information connects to IoT and sensor data to give operators complete visibility into how assets and systems are running. In practice, this means installing sensors on equipment (temperature gauges, vibration sensors, cameras, etc.) and feeding those readings into the twin model.

This IoT integration turns a static model into a living one. As SAS analysts explain, digital twin technology “uses cloud-connected sensors embedded in machines to upload real-time operational data, producing up-to-date virtual simulations of real-world machines.” In other words, the digital twin becomes a continuously refreshed mirror of the asset. By analyzing this live data, engineers can detect anomalies immediately, predict when parts will wear out, and even automate responses. With scan data, the data can be integrated into the 3D view, allowing users to access the feed attached to the digital twin from anywhere, at anytime in Cintoo.

Metadata and context also play a key role in making the twin meaningful. Asset identifiers, location tags, or links to manuals can be embedded in the model so that each part’s live data is correctly interpreted. When this is done well, the digital twin provides a visual, always-current source of truth for the entire system. Facility managers can virtually walk through the twin and see sensor values overlaid on the 3D model, checking conditions anywhere. Over time, the twin accumulates historical and current metadata so the model itself becomes as valuable as the physical asset. In sum, IoT and metadata transform the twin into a dynamic, real-time representation: a digital asset that lives and evolves alongside its physical counterpart.

Cintoo’s platform is designed to help companies build and use digital twins from real-world scan data. It starts by converting raw 3D laser scans into high-fidelity 3D meshes. Using its patented TurboMesh™ technology, Cintoo preserves the full detail of point clouds in lightweight mesh surfaces. This means that millions of laser scan points become an accurate 3D model that is easy to stream and view. In practice, Cintoo’s cloud service ingests point clouds and produces ready-to-use meshes of facilities, plants, or infrastructure.

Crucially, Cintoo is built for openness and interoperability. Its APIs and SDKs allow customers to integrate the Cintoo mesh data into other digital twin and analysis platforms. As described by one review, “Cintoo Cloud’s APIs and SDKs allow seamless integration with other platforms, supporting automated workflows and eliminating data redundancy”. In practical terms, that means a company can stream Cintoo’s meshes into a GIS or BIM system without cumbersome file exports. For example, Cintoo has developed an Esri ArcGIS widget so that users can bring live 3D mesh content directly into geospatial workflows.

By focusing on accurate 3D data and open connectivity, Cintoo helps customers achieve reliable digital twins. The platform turns scan data into a centralized 3D model where actionable data can be utilized more efficiently. This enables cross-industry teams (in manufacturing, energy, facilities management, etc.) to easily plug Cintoo-based twins into their existing tools. In other words, Cintoo provides the digital-mesh foundation and the connectivity that make scan-based digital twins possible. The end result is that organizations can maintain an always-current 3D source of truth for their built assets – while having the flexibility to integrate that data into any Industry 4.0 application or platform.

Want to explore more and transform your digital twin to streamline actionable data?