Cintoo for us has really democratized point cloud data so that it becomes the deliverable standard. Our engineers are leveraging these data sets regardless of what region they're in,

John Brown

Supervisor in General Motors’ Reality Capture division

These days, large-scale industries are relying on Reality Capture technology even more to perform plant and facility updates, including changing equipment and designing new layouts based on as-installed conditions. The need for reality capture data is paramount to teams especially in the Automotive & Manufacturing industry, where laser scanning of plants and facilities provides massive point clouds that can be utilized in innovative ways.

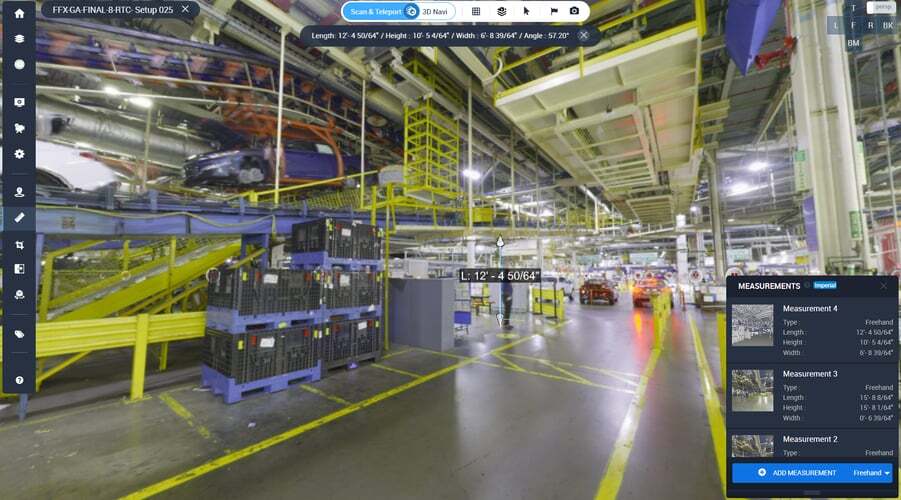

View all equipment within the Cintoo platform

General Motors, one of the largest suppliers of automotives around the world, is taking their reality capture solutions to the next level by utilizing laser scan data in almost every design and build decision they’re making on their factory floors. John Brown, a Supervisor in General Motors’ Reality Capture division, describes states how, “Cintoo for us has really democratized point cloud data so that it becomes the deliverable standard. Our engineers are leveraging these data sets regardless of what region they're in, could be South America, China, India, Korea, it's really made us even more of an international company from an engineering standpoint.

.webp?width=1890&height=1057&name=image-6-1%20(1).webp)

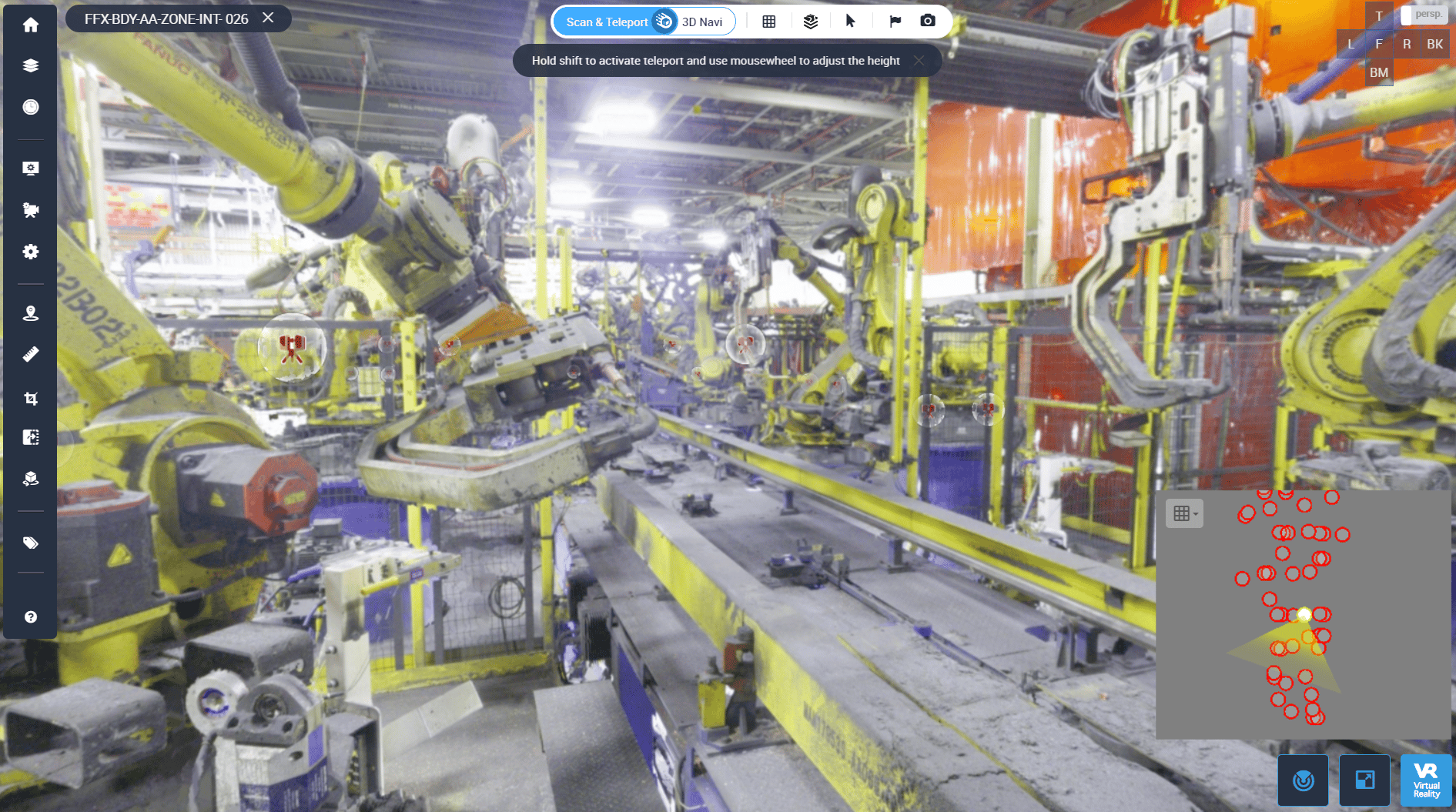

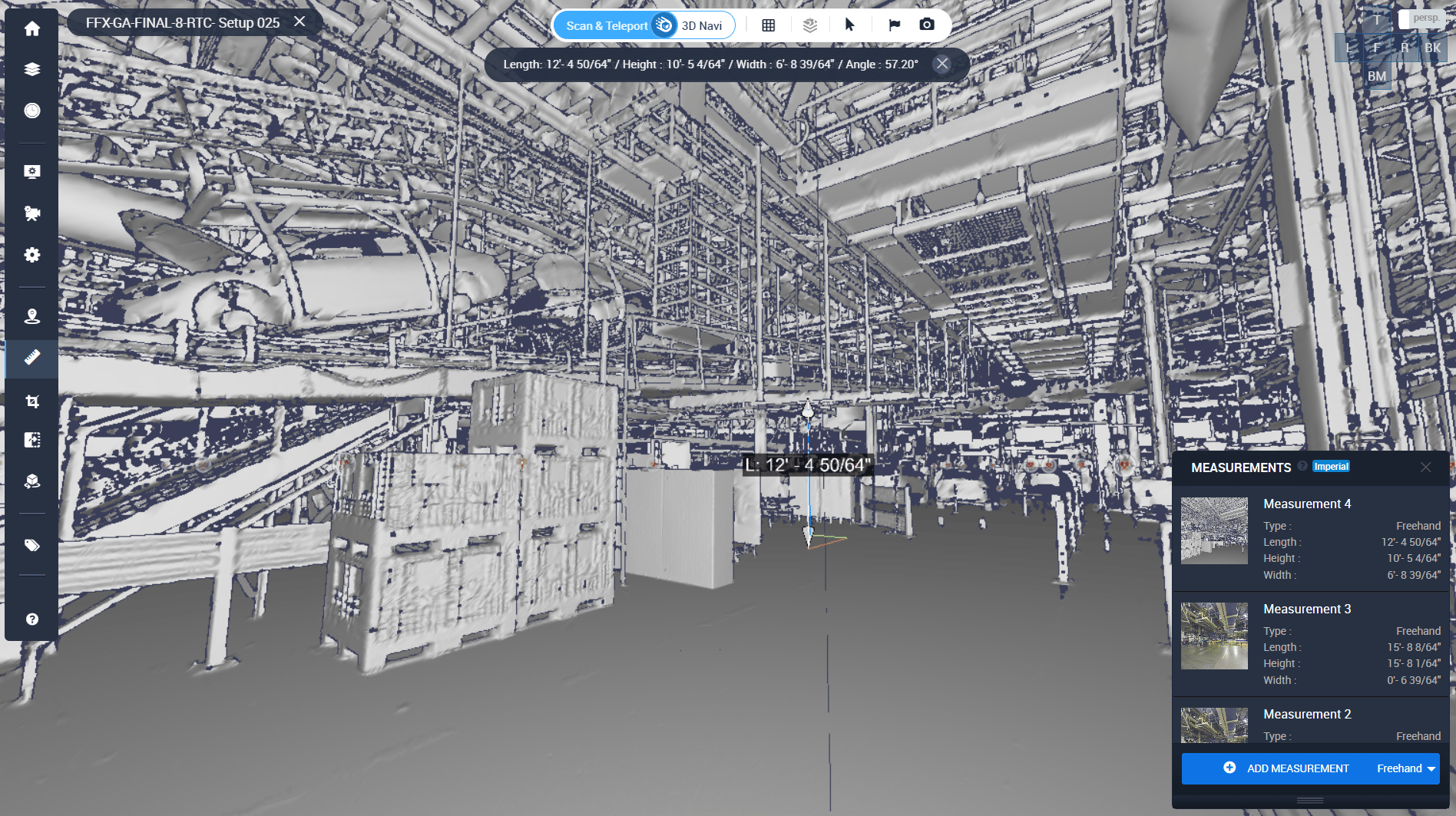

Equipment is highly detailed in the 3D mesh view.

First, General Motors obtains reality capture data through laser scanning. “The whole reason we even got into laser scanning was to understand the current as-installed conditions of our facilities. It's not just delivering cool, immersive data that matters, but really capturing data that has an engineering aspect and business benefit to it. Cintoo has made it really easy for us to make comparisons between our math data and as-installs so that we can see any differences,” John says. Having total visualization of differences between the model and as-installs not only saves time, effort and money in the long run, but also becomes embedded in workflows, helping to eliminate surprises completely. “The visual scope in Cintoo has immense value. What our team has done is reduce the number of surprises and surprises cost money.” John goes on to describe how certain capabilities in the Cintoo platform, paired with the scan-to-mesh conversion of point cloud data, helps his team identify, tag, and push issues which further eliminate costly surprises.

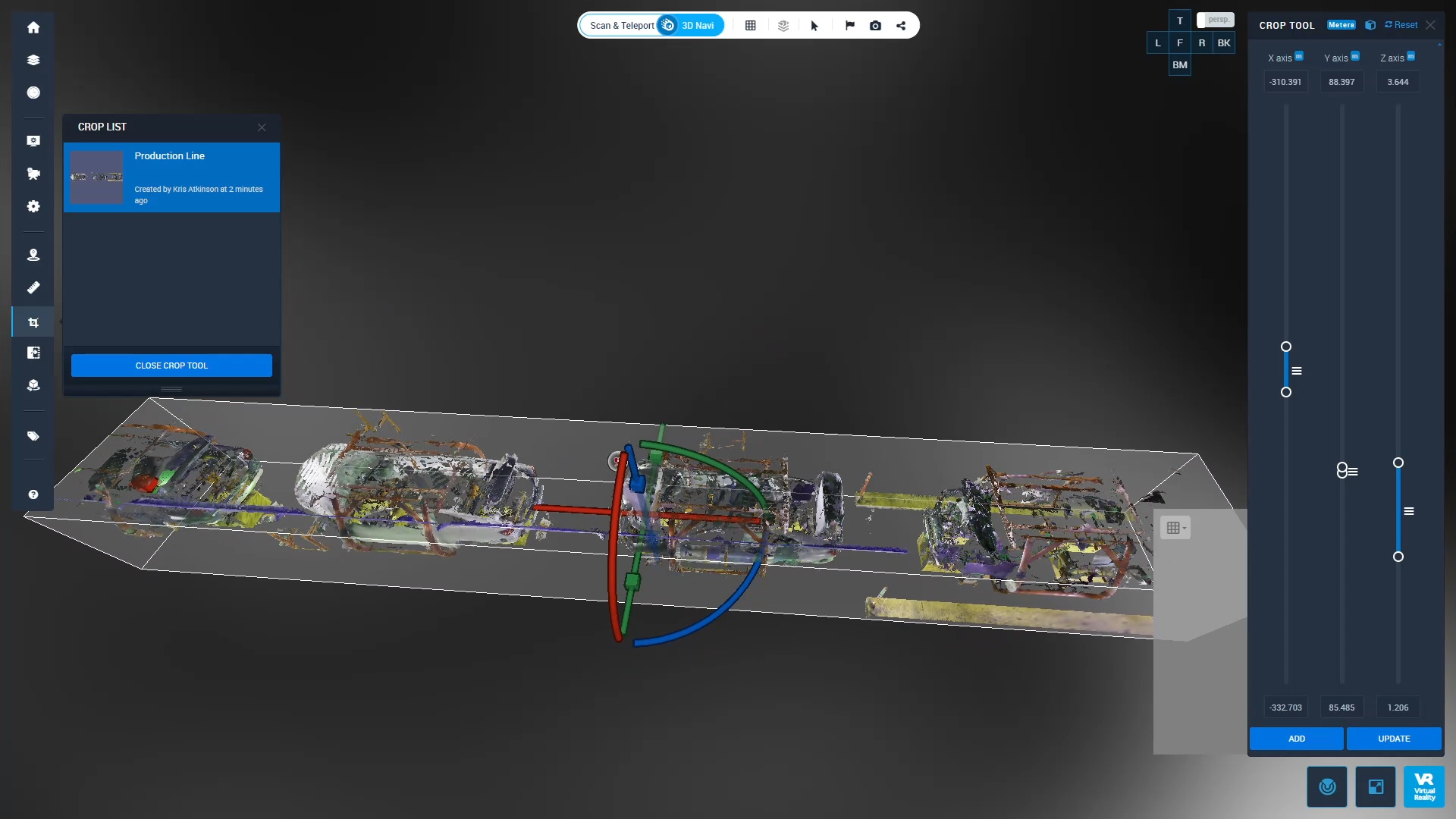

Use navigation and crop capabilities to view specific areas, including the production line.

Conducting laser scanning is a massive endeavor in and of itself due to the unbelievably huge square footage of some plants and facilities. “We capture everything from the fences down to a specific bolt for a robot on the floor, and we may use five different types of scanners, cameras or drones to do that,” John says. Given the huge quantities and file sizes of point cloud data, it all needs to be managed and Cintoo provides a direct way to compress the data. Point cloud data is converted to 3D meshes in Cintoo, made accessible to other teams at General Motors including GM suppliers, contractors and vendors from all different domains. All of these teams benefit from immediately accessing the as-built environment in Cintoo. “We have positioned ourselves so that as changes are made in the plant, we don't have to go back in and capture 4 million square feet of floor space. We quickly update the information in Cintoo,” John says. “For my team, I can see the hundreds of suppliers that are accessing our plant data at any given time daily. There's always somebody in there looking at data, but what this really has done for us is it gives suppliers the flexibility to reach in and grab data as they need it. Just giving them that flexibility has really streamlined their approach to how they're estimating, engineering and installing things in our facilities,” John explains. The idea that key suppliers working closely with GM can have instant access to the 3D environments speaks to the amount of collaboration that Cintoo helps foster between teams.

A 3D mesh and Surface mode view of the same complex area, complete with conveyor belt equipment.

In the future, John envisions more frequent use of reality capture technology in GM plants, including updates made to these facilities every quarter. In these ways, specializing in data capture means not only performing more routine laser scans, but also becoming more holistic in how that data is used across teams. “There’s a need to specialize in data, not just data capture, so that the teams at General Motors can keep things up to date and accessible for our customers. We want to make sure everybody has access to it, to the most current, most up to date and most accurate data that we can, and Cintoo's really allowed us to do that,” John says.

GM - General Motors is one of the largest automobile suppliers in the world driving smart technology solutions for greater innovation.

Supervisor in General Motors’ Reality Capture division