Effective issue tracking is critical in today’s complex construction projects. Issues – from design conflicts to field errors – drive rework and delays. In fact, industry studies show construction rework often costs around 5–10% of total project value. Poor communication and collaboration are a leading cause of these overruns. By systematically logging and managing issues, teams can ensure coordination, uphold QA/QC standards, and verify as-built conditions against the design model. A robust issue-tracking system improves efficiency and visibility, helping all stakeholders catch discrepancies early and keep the project on schedule.

Traditionally, teams have managed issues via spreadsheets, emailed drawings, or PDFs, but these fragmented methods create silos. “Traditional QA/QC methods are siloed and inconsistent,” observes one report, resulting in fragmented awareness and slow resolution. Even digital spreadsheets can’t fully solve the problem if the site photos, BIM models, and reports live in separate systems. In practice, this disconnect leads to incomplete trend tracking and delays in resolving issues. For example, emailed markups can be overlooked, out of date, or lack context. Manual processes also make it hard to trace issues to specific model elements or locations, so mistakes can recur. As a result, teams waste time chasing information and fixing the same problems multiple times – undermining project quality and wasting budget.

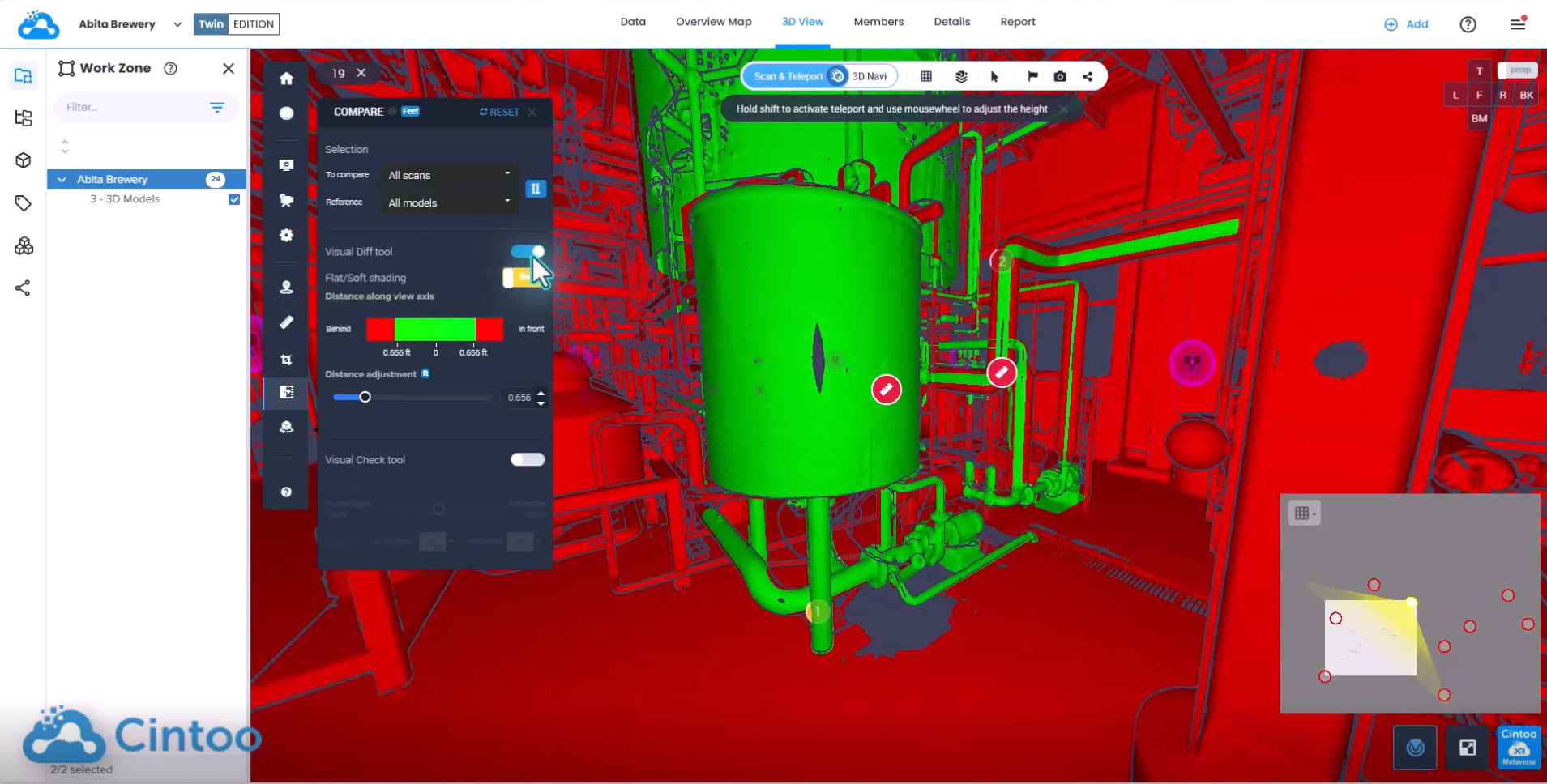

Modern Building Information Modeling (BIM) and Virtual Design & Construction (VDC) tools provide a better foundation for tracking issues. When project teams integrate scan-to-model comparisons into their workflow, they gain an objective view of construction progress and deviations. For instance, 3D laser scans of the site can be overlaid with the BIM model to highlight missing or mis-built elements. This as-built evaluation lets teams pinpoint where construction differs from the design, down to millimeter tolerances. Automated clash detection tools also play a role: by identifying model conflicts (e.g. an MEP duct that clashes with structural framing), they generate issues within the BIM environment to be resolved before construction proceeds. In a unified BIM/VDC workflow, these conflicts become tracked issues that can be assigned, prioritized, and audited – closing the loop between design coordination and field execution.

.png?width=512&height=227&name=unnamed%20(1).png)

More specifically, when the BIM model is aligned with real-world data (scans or point clouds), discrepancies instantly turn into assignable issues. Cintoo simplifies this integration by streaming mesh-based scans alongside BIM/CAD models in a web viewer. Users can navigate through the combined 3D scan data environment, managed all through a web-based browser, and mark up problems, attach notes, photos, or use the annotation tool in Cintoo to keep track. Because everything is tied to the model geometry, teams can instantly see which subcontractor or trade is responsible. This approach supports multiple model formats – Revit (.rvt), Navisworks (.nwd/.nwc\), and IFC – ensuring that whatever design tools are used, their data can be directly compared to reality capture data in Cintoo. The result is a visual, virtual workflow: one click reveals all current issues on each element, flagging quality control and coordination problems long before field work is complete.

Importantly, integrating issue tracking with BIM/VDC workflows has measurable benefits. By detecting deviations early, teams avoid costly rework later. For example, a Cintoo case study notes that scan-to-model progress monitoring can reduce rework by up to 50% and deliver a 3–5× return on investment. In practice, this means catching a misplaced beam or a missing wall in the digital twin, not on site as changes occur. Tracking actual progress against schedule with 3D scans also helps managers spot delays or omissions in real time. Overall, these digital QA/QC workflows transform quality control from a reactive afterthought into a proactive, data-driven process.

True productivity comes when issue tracking bridges design and field teams. Modern platforms let teams push issues across tools. For example, Cintoo enables annotations created during scan-to-model reviews to flow into construction management systems. A team member can tag a deviation in the 3D scan environment via Cintoo (with metadata like severity, photos, or hyperlinks), and then push it to Procore for instance. This creates a live issue in the contractor’s field app linked back to the scan. Now, Cintoo has developed an automatic Progress Monitoring web service to quantify BIM versus scan coverage gaps and create CIPM reports. Utilizing script-based processes, the CIPM to issues tool analyzes the computed scan coverage for each selected BIM model element listed in this report to generate issues directly within Cintoo. Then, they are exported as BCF (BIM collaboration format) files. This seamless integration enables your teams to document and detect the BIM model elements that that may not be built yet. Streamline your construction monitoring process, reduce manual oversight, and ensure that construction goes according to the design intent.

-1.png?width=6912&height=3456&name=Untitled%20design%20(61)-1.png)

In practice, this means a clash found in the scan data can generate a cloud-based issue that designers see in their model authoring tools, and builders see in the field management app. Procore’s integration with Cintoo, for instance, explicitly allows creating issues from scan-versus-design comparisons and sending them into Procore. The advantage is clear – all stakeholders work from the same issue list. Designers review fixes in their models, quality teams update scans or tag completion in the cloud, and field crews get automatic updates and preparation. No more emailing updated punch lists or maintaining separate spreadsheets. In summary, seamless integration of issue tracking into both BIM and field platforms ensures that every issue is visible, actionable, and resolved in context.

Cintoo exemplifies how automated workflows streamline issue management. In a recent demonstration (“Mastering Construction: As-Built Evaluation and Issue Tracking”), a project team used Cintoo to handle dozens of issues identified via scan data. The team first uploaded 3D laser scans of the site and the corresponding Revit/Navisworks model into Cintoo’s browser viewer. The platform automatically aligned the as-built mesh to the design geometry. Issues stood out as highlighted gaps or overlaps in the model. Users could click on any problem area in the 3D viewer and instantly create an issue note, attaching details like photos, labels, due dates, or severity tags. Each issue was linked to the exact 3D location and model element, preserving full context

From there, Cintoo enabled collaborative resolution. The system pushed these cloud-created issues directly into the project’s workflows: for example, syncing them to Procore as Observations so field managers could assign trades and schedule fixes. Alternatively, the issues (in BCF format) could be imported back into Navisworks or Revit through plug-ins like BIM Track or Newforma Konekt. In each case, the issue remained tied to the scan and model. For instance, clicking an issue in Procore would show a link back to Cintoo’s viewer, where progress could be re-scanned and verified. Meanwhile, designers could view all reported issues on their as-designed model, making the clash-resolution loop instantaneous.

Because Cintoo’s workflows span the whole project team, they cut down on duplicative tasks. The system automatically generates periodic reports of unresolved issues, linked to specific elements and views, eliminating manual data entry. Teams receive notifications when scans are updated or an issue’s status changes. The net effect is a truly digital QA/QC process: rather than paper checklists, every issue flows in real time through the cloud, with full history and accountability. This kind of integration enables real-time model overlays, annotation, and model discrepancy reporting, meaning a single truth for all stakeholders.

The benefits are quantifiable. By using Cintoo's issue tracking in tandem with BIM/CAD modeling software, teams report fewer field errors and improved coordination. Clashes and mistakes uncovered early in the scan data prevented costly change orders later. Design teams could correct models and immediately push updates to the field, ensuring build teams had the latest information. The end result was higher model fidelity, less wasted labor and materials, and faster closeout. Studies suggest the ROI can be dramatic: organizations that capture issues in 3D and resolve them in an integrated system see up to 5× returns by cutting rework and delay costs.

In summary, modern construction issue tracking relies on digital integration. By leveraging BIM models and scan-to-BIM comparisons in Cintoo, teams transform a tedious process into a collaborative workflow. As the industry shifts toward reality capture and digital twins, it's due time to connect design, field, and QA/QC teams. This unified approach keeps the project on track by ensuring that every issue – from a tiny pipe clash to a major structural error – is visible to the right people at the right time, and resolved before it becomes a costly problem.

Register for a free demo today to see how to take your QA/QC process one step further!