The Comprehensive Guide to Asset Tagging in 3D Scan Data

- Madeline Medensky

- March 12, 2025

Asset tagging is an essential process in modern industries, providing a systematic approach to track and manage physical assets. When combined with the power of 3D scan data, asset tagging becomes a transformative tool, revolutionizing the way organizations monitor and maintain their valuable resources. This article explores the asset tagging process, its benefits, and how it integrates with 3D scanning technology and 3D scan data. Along the way, we'll cover essential concepts like NFC tags, unique identification numbers, and the role of advanced tracking systems.

What is Asset Tagging?

Asset tagging is the process of affixing a unique identifier, such as an RFID tag, QR code, or NFC tag, to an asset. These tags store essential information, enabling users to track assets in real time and maintain detailed records for inventory management, maintenance, and repair.

When combined with 3D scan data, asset tagging offers unprecedented precision and enhanced metadata. By embedding asset tags directly into the digital representations of physical items, organizations can streamline processes and ensure efficient tracking of their assets in virtual and physical realms.

Facilities and construction sites can involve complex asset ecosystems.

The Asset Tagging Process

The asset tagging process involves several critical steps, ensuring each asset is uniquely identified and effectively tracked:

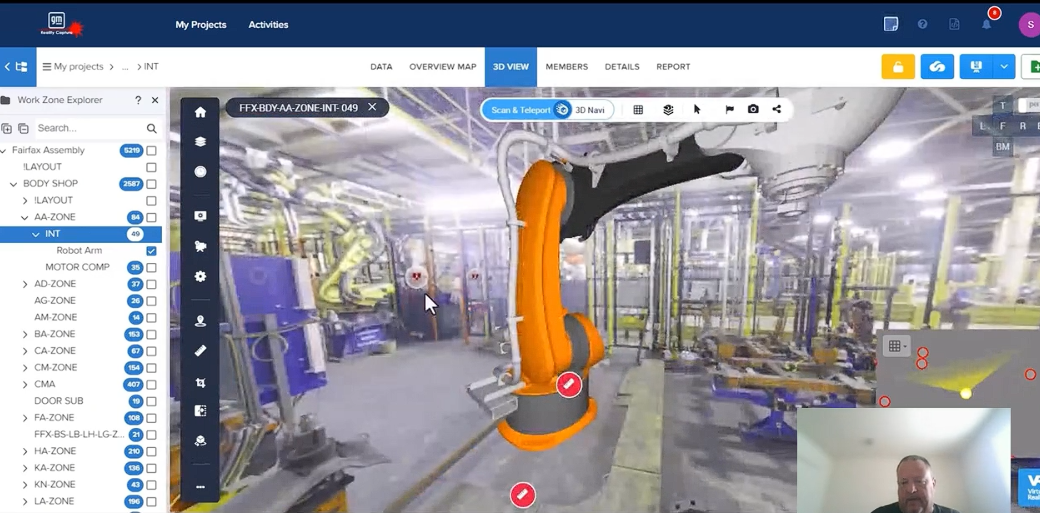

Identify Assets for TaggingDetermine which assets require tagging. Common candidates include machinery, tools, equipment, and high-value items. This way, their ability to be continuously analyzed is identified by the tag, including the incorporation of metadata. Metadata for a tag refers to its attributes such as labels, class of tags, description, hyperlinks to Digital Twin, ERP and EAM platforms. Remember, the use of digital twins allows for seamless asset management, since digital twins are populated from 3D scan data, making a virtual representation of a physical space and asset.

3D scan data embedded into digital twin workflows.

Choose the Type of Asset TagDepending on the environment and use case, select the most suitable tag. Common types of asset tags include:

- QR codes: Ideal for simple, visual scanning.

- RFID tags: Perfect for long-range, bulk tracking.

- NFC tags: Best for short-range interactions with smartphones or specialized readers.

Each tag is associated with a unique identification number, ensuring every asset is distinct and easily findable.

Affix the Asset TagTags are physically attached to the asset, ensuring durability and ease of scanning.

Integrate with an Asset Tracking SystemConnect the tagged assets to an asset tracking system to manage their data, monitor usage, and plan for maintenance and repair.

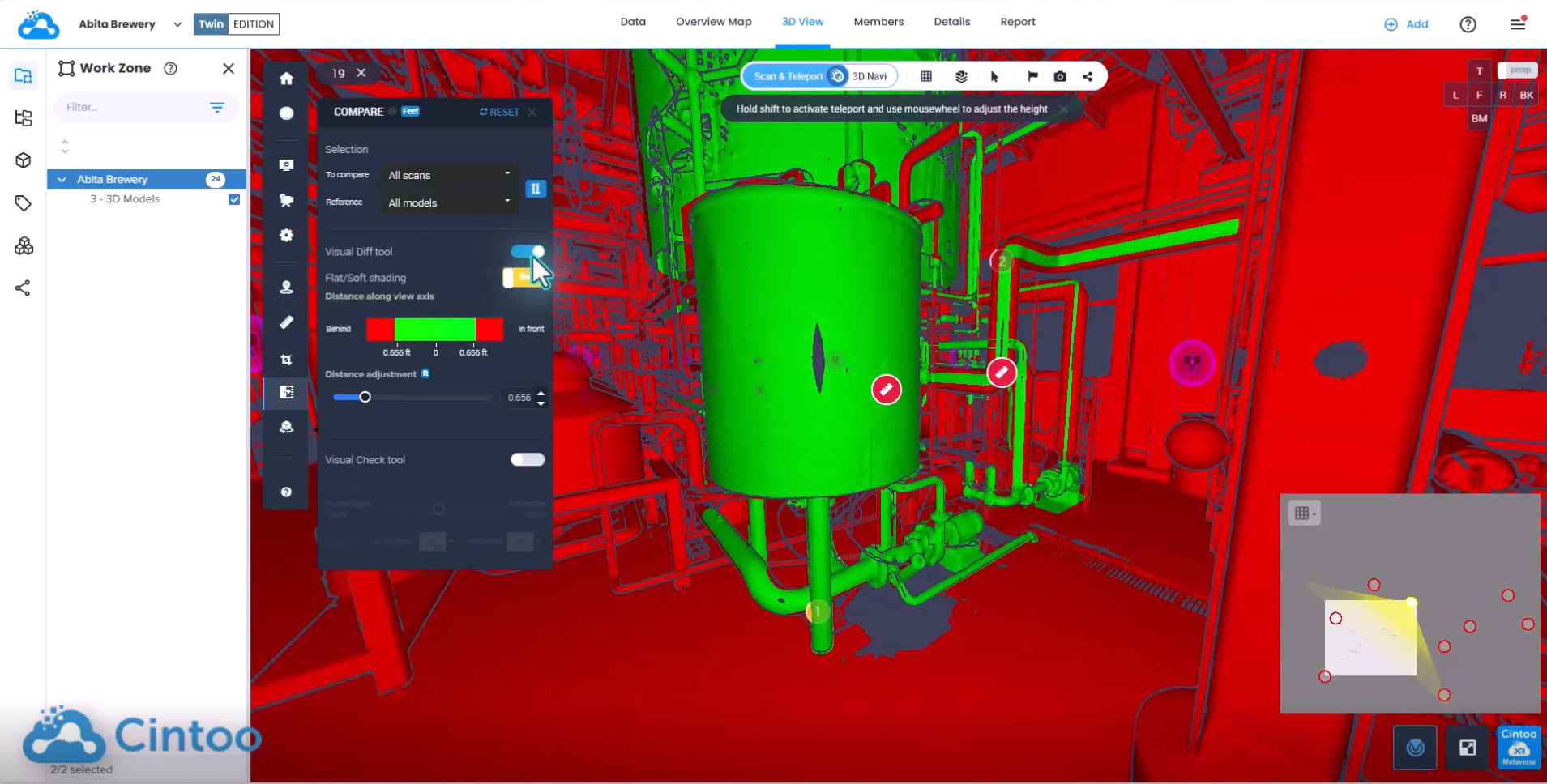

Leverage 3D Scan DataUse 3D scanning technology to create digital twins of your assets, embedding tag information directly into these virtual models. These digital twin workflows directly mirror the as-built conditions of an asset or class of assets.

Benefits of Asset Tagging in 3D Scan Data

The integration of asset tagging with 3D scan data offers numerous advantages:

Enhanced Visibility: Tracking assets in real-time becomes more efficient with 3D visualization. Users can quickly locate items within a digital model of their facility.

Streamlined Maintenance and Repair: By associating tags with 3D models, maintenance teams can access detailed information, like repair history and specifications, at a glance.

Improved Asset Lifecycle Management: Combining asset tagging with 3D scans allows organizations to monitor wear and tear, optimize replacement schedules, and extend asset lifespans.

Monitor the lifecycle of an asset seamlessly.

Accurate Inventory Tracking: Digital twins integrated with asset tags ensure precise inventory management, reducing the risk of lost or misplaced items.

Reduced Downtime: Real-time data from asset tags minimizes delays in locating or repairing equipment.

How NFC, RFID, and QR Codes Transform Asset Tagging

Modern asset tagging systems leverage advanced technologies to provide scalable solutions for tracking and managing assets:

- NFC Tags: Perfect for environments where short-range interaction is sufficient, such as office equipment or IT assets.

- RFID Tags: Suitable for large-scale operations like warehouses or manufacturing plants, where long-range scanning is necessary.

- QR Codes: A cost-effective option for environments with visual access to assets.

Each of these tags includes a unique identifier, which is linked to detailed asset information within an asset tracking system.

Real-Time Tracking with Asset Tagging Systems

A robust asset tagging system ensures assets can be tracked and managed in real time. This capability is particularly critical in industries like construction, healthcare, and logistics, where rapid access to asset data can significantly impact efficiency.

For example, construction firms use asset tagging to monitor tools and equipment, ensuring they are available when needed. Likewise, in manufacturing environments, site conditions involve complex mazes of assets that need continual maintenance. When Axalta, one of the global coating manufacturers in the world, embraced digital workflows to streamline its operations, they found a new way to maintain equipment too. “By using Cintoo to review our as-built data, site visits have been significantly reduced, leading to time and cost savings within our projects,” explains Marco Shuh, BIM/CAD Administration Engineering at Axalta Coating Systems.

![]() Key Considerations in Asset Tagging for 3D Scans

Key Considerations in Asset Tagging for 3D Scans

When implementing asset tagging with 3D scan data, consider the following:

Tag Placement: Ensure tags are affixed in a location that is both accessible for scanning and visible in the 3D model.

Environmental Factors: Select tags that can withstand the conditions of the asset’s environment, such as heat, moisture, or vibration.

Data Security: Protect the data stored on tags and within the tracking system to prevent unauthorized access. When using a software platform for the processing of 3D scan data, it’s important to ensure security requirements are up to grade. For instance, Cintoo has recently received ISO27001 verification status, alongside SOC2. These are important for consideration when choosing a 3D scan data platform.

System Integration: Ensure the tagging system integrates seamlessly with 3D modeling software and other asset management tools.

Use Cases of Asset Tagging in 3D Scanning

The combination of asset tagging and 3D scan data has applications across various industries:

Manufacturing: Track production equipment and spare parts, reducing downtime and improving efficiency.

Aerospace: Monitor high-value components in aircraft maintenance, ensuring compliance with safety standards.

Oil and Gas: Enhance pipeline inspections by associating asset tags with 3D scans of infrastructure.

Construction: Track equipment and monitor asset-intensive environments seamlessly.

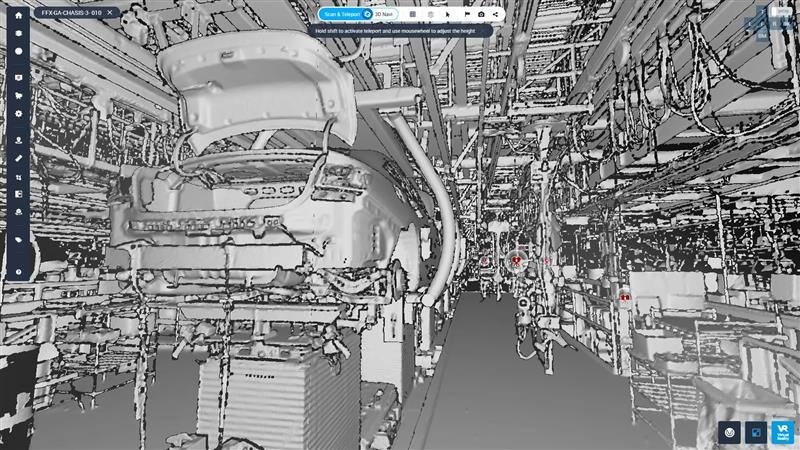

How 3D Scan Data and Asset Tagging Is Joined Together

Digital visualization of as-built conditions depends on 3D scan data, harnessed from laser scanners that collect data points. Choosing a platform to house the 3D scan data is vital to making the most of 3D scan data workflows. With Cintoo, there are no limits to the amount of laser scan data that can be uploaded and streamed without compromise to accuracy or resolution.

Once in Cintoo, 3D scan data workflows enable asset management, display and tracking with the ability to add annotations where needed. This means that you and your team can rely on asset management virtually and collaborate without risk.

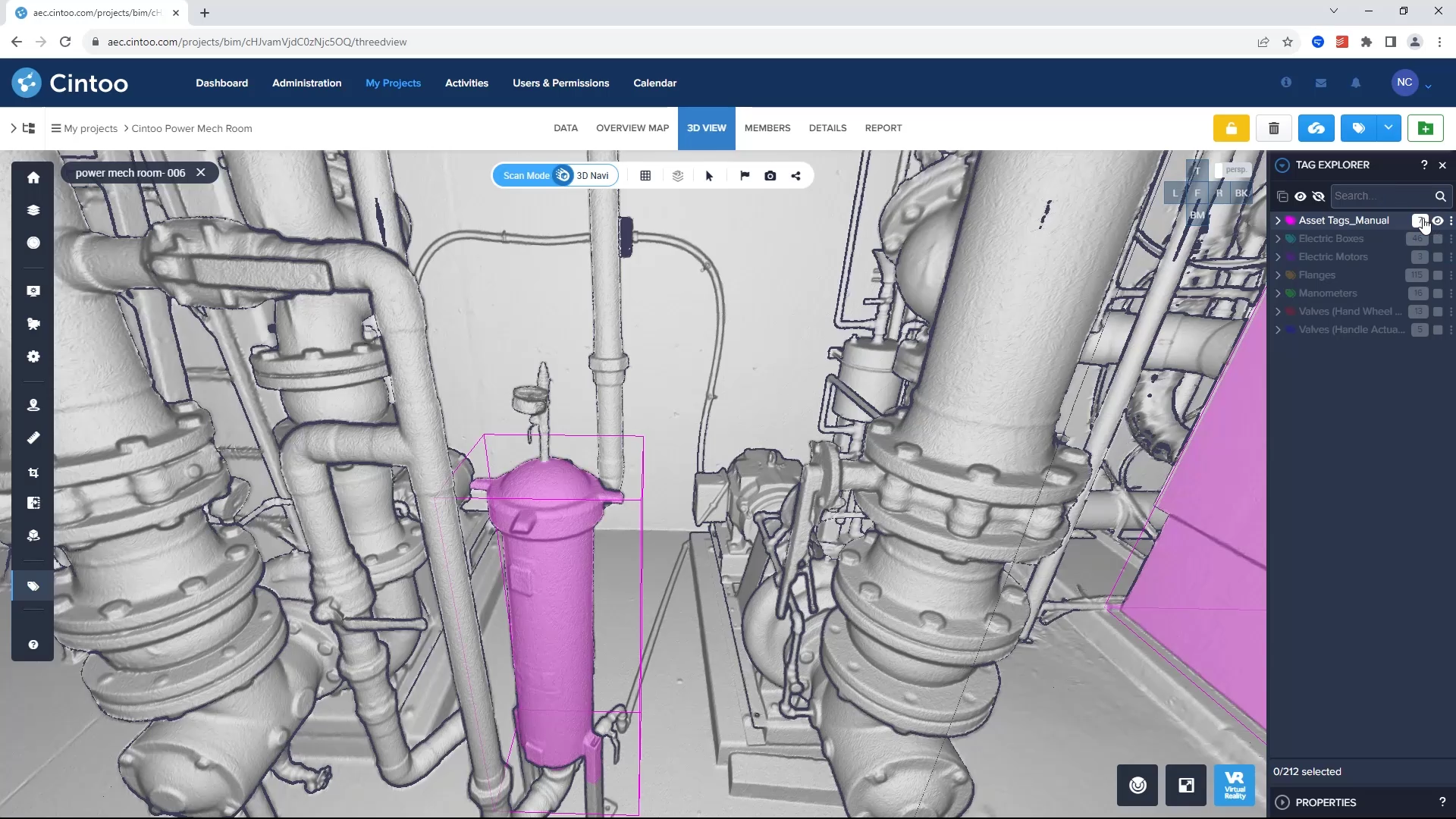

Once uploaded to Cintoo, these digital assets are your greatest source of visual truth compared to outdated BIM or CAD models. Asset tagging and display tools in Cintoo allow you to link physical equipment or parts to their digital counterpart.

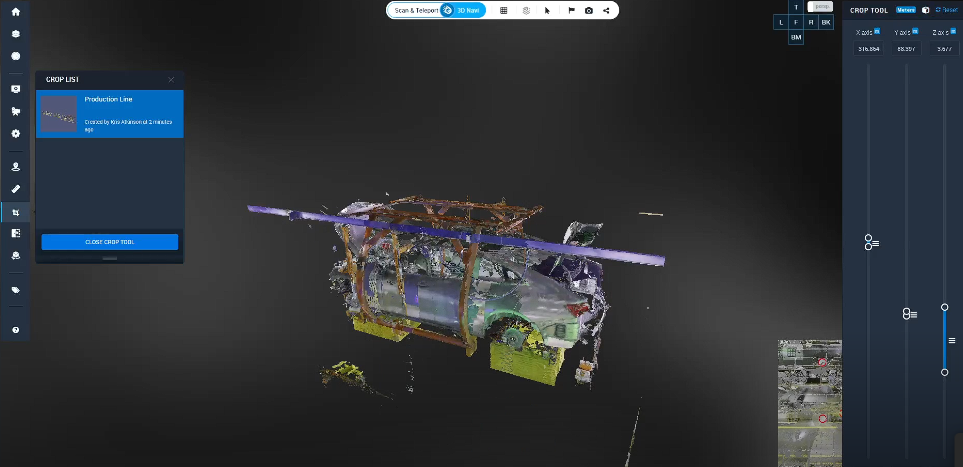

Cintoo’s 3D view brings a unique viewing power to asset management.

Cintoo asset tags reference your selected assets with a bounding box and unique ID. Tags can be viewed in their as-built context using Cintoo's 3D view. Bring your scanned as-built data into Cintoo’s collaborative workflows using this single source of trustful information for asset management and predictive maintenance.

Tailored to your company’s needs, the extraction of data becomes intuitive and easy to manage across the lifecycle journey, saving you time and money.

Future Trends in Asset Tagging and 3D Scanning

The future of asset tagging lies in the convergence of technologies like IoT, AI, and augmented reality. Advanced systems will not only track assets but also provide predictive analytics, enabling organizations to anticipate and address potential issues proactively. For instance, Cintoo has implemented their AI Classification Toolkit, meaning you can seamlessly classify assets or groups of assets automatically now, saving you even more time.

Asset tagging, when combined with 3D scan data, is a game-changer for organizations seeking to track and manage assets efficiently. By integrating technologies like NFC tags, RFID tags, and QR codes with detailed digital models, businesses can unlock the full potential of their resources. From improving maintenance and repair workflows to tracking assets in real time, the benefits of asset tagging are undeniable.

As industries continue to evolve, the adoption of advanced asset tagging systems will become increasingly crucial. Organizations that embrace this technology today will be better positioned to adapt to tomorrow’s challenges, ensuring sustainable growth and operational excellence.

Whether you're new to the concept or looking to enhance your existing systems, investing in asset tagging and 3D scanning is a step toward a more efficient and innovative future.

Check out Cintoo’s latest ebook: Asset Management & Digital Twins: It’s all about As-builts and Tags.