3D Reality Capture Workflows for AEC and Industry40

- Madeline Medensky

- March 18, 2025

Understanding 3D Reality Capture: Precision and Efficiency

3D reality capture is changing how industries document and interact with physical spaces. By creating highly accurate digital representations, this technology enhances efficiency, reduces costs, and improves collaboration across architecture, construction, manufacturing, and cultural heritage preservation. Central to 3D reality capture are detailed 3D models generated from point clouds—collections of data points representing spatial dimensions. These point clouds serve as the foundation for Building Information Modeling (BIM) and Computer-Aided Design (CAD) applications, enabling precise digital modeling and visualization. This article explores the end-to-end workflow from laser scanning to point cloud processing and integration into BIM/CAD platforms. It also examines various use cases, compares laser scanning with photogrammetry, and discusses the benefits of adopting a 3D reality capture workflow.

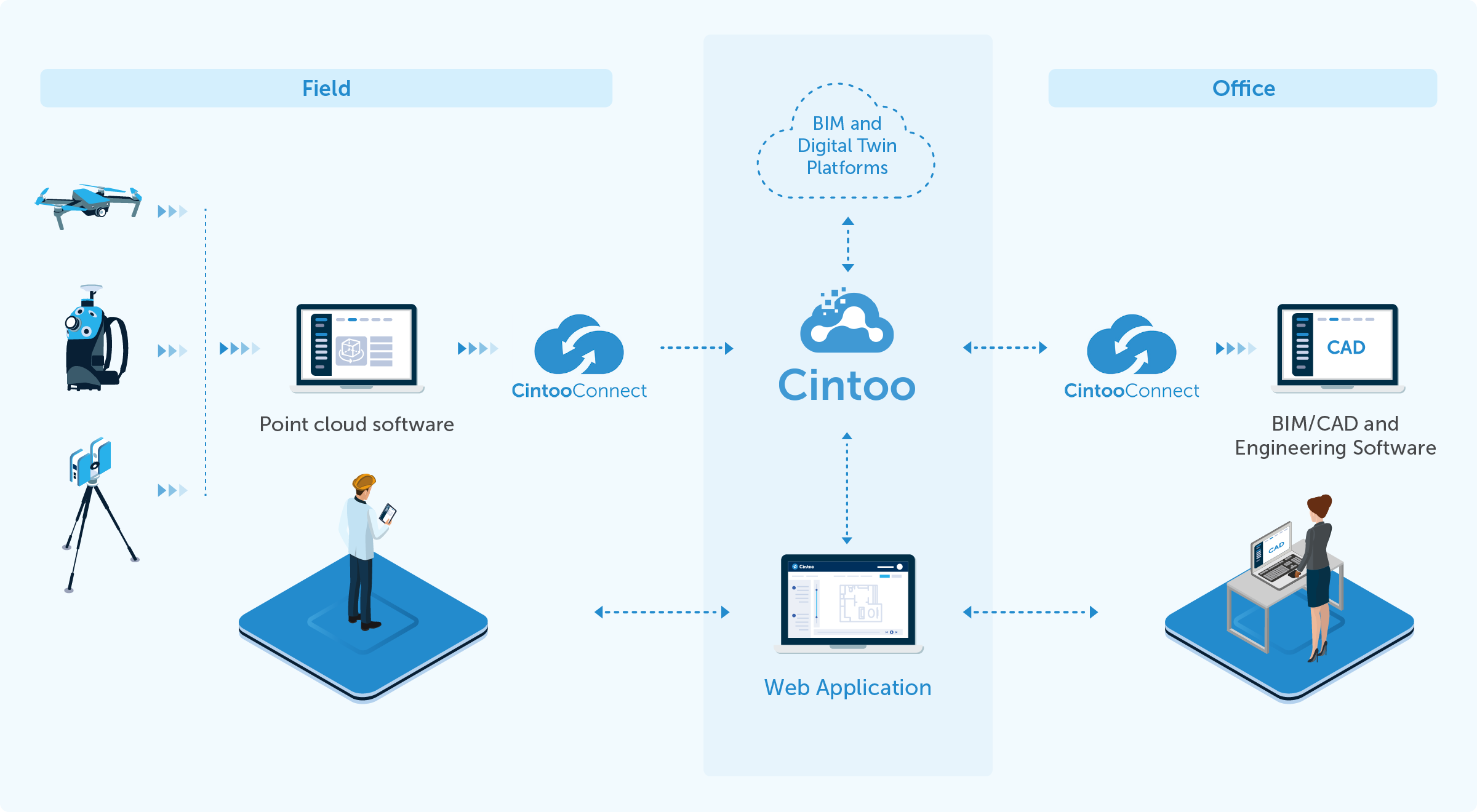

The Process: From Laser Scanning to BIM/CAD Integration

The journey from laser scanning to integrating data into BIM and CAD models involves several key stages, each contributing to an accurate and detailed digital representation of the physical world - mostly known as a digital twin. Understanding this workflow is essential for industries looking to leverage 3D reality capture to its fullest potential.

Data Acquisition through Laser Scanning

Laser scanning is the cornerstone of accurate 3D reality capture. This method employs laser scanners that emit laser beams to capture the geometry of physical structures. As the laser contacts surfaces, it records precise measurements by calculating the distance between the scanner and the object. These measurements generate a collection of data points known as a point cloud, where each point is defined by specific coordinates (X, Y, Z) and may include additional attributes like reflectivity or color. The result is an accurate digital replica of the physical environment, capturing even the most intricate details.

Laser scanners can capture millions of points per second, ensuring a comprehensive spatial representation. This method is highly effective for complex structures with intricate details, such as industrial facilities, historical landmarks, and commercial buildings. It also offers unmatched precision, making it indispensable for tasks requiring high accuracy, such as construction validation and quality control. Additionally, laser scanning reduces human error in measurements, enhances safety by minimizing physical site visits, and accelerates project timelines by efficiently capturing spatial data.

Processing Point Cloud Data

After capturing the raw point cloud data, the next step involves processing to remove noise, align multiple scans, and create a unified dataset. This is achieved through point cloud registration, where overlapping scans are aligned using reference points. The resulting consolidated point cloud provides a detailed 3D representation of the scanned area, serving as the foundation for creating accurate 3D models.

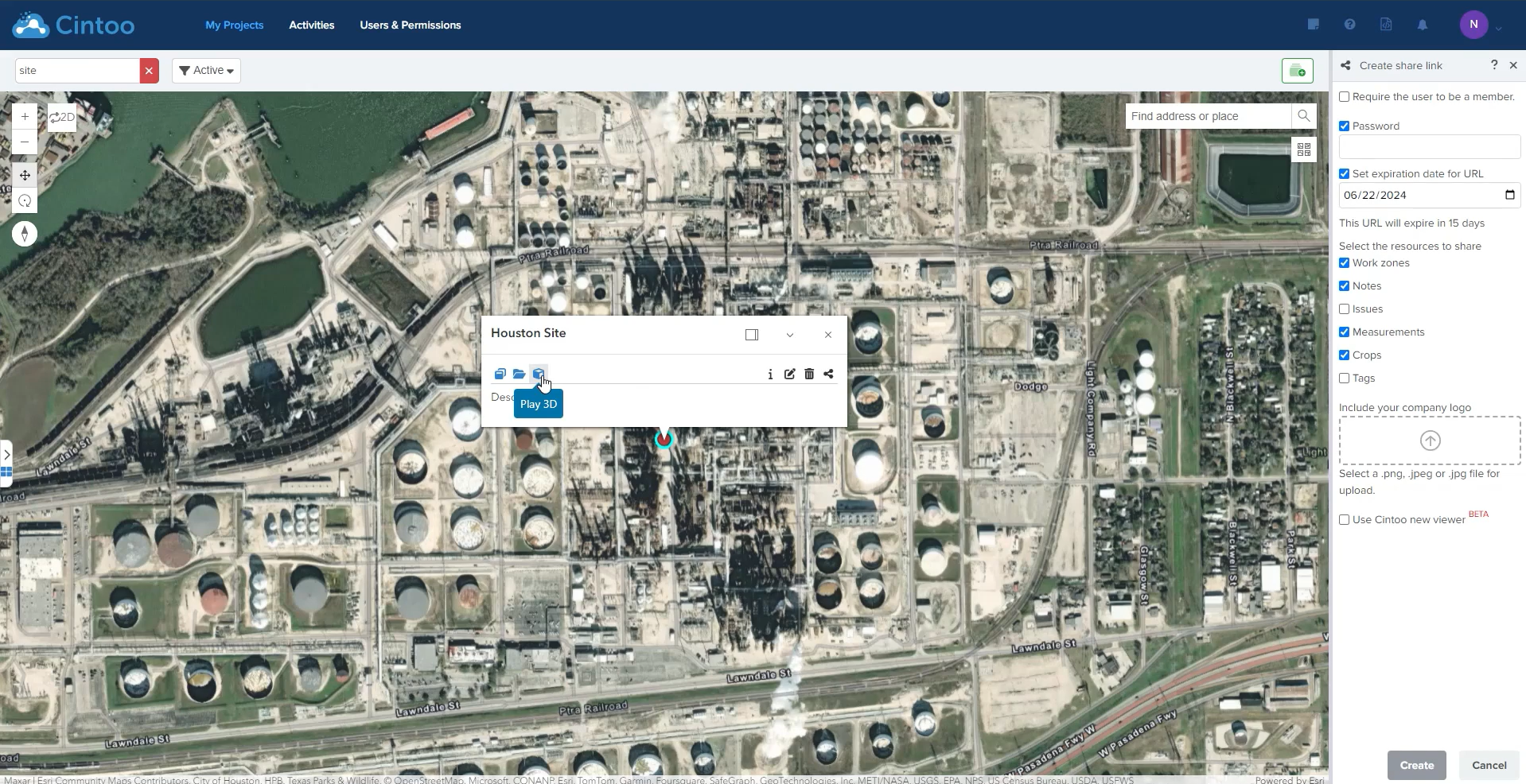

Specialized software solutions can facilitate the processing, like the Cintoo platform which compresses huge point cloud data sets into high-resolution 3D meshes, meaning there’s no compromise to accuracy and project teams can finally eliminate hard drives as a mainstay source of point cloud data. Cintoo is a cloud-based application, meaning anyone can have access, no matter where they are in the world, through a simple web link.

Seamless mesh compression for high-quality visualization.

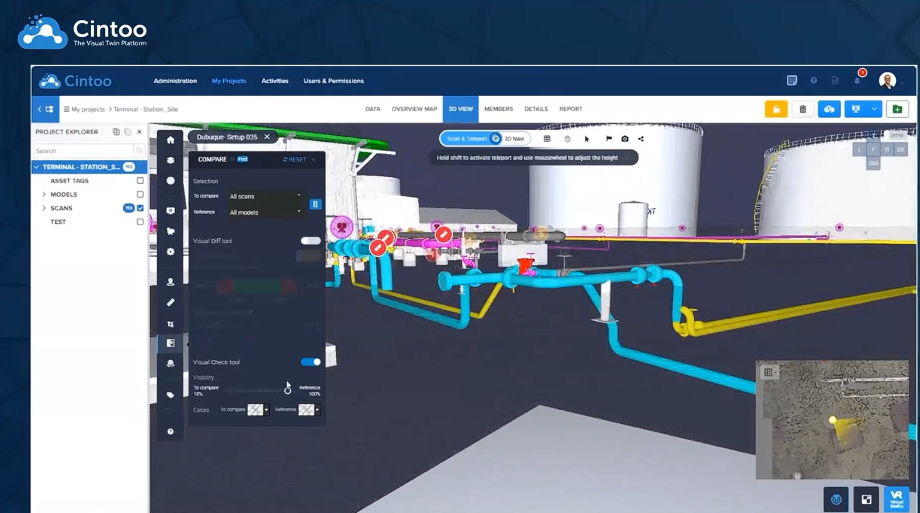

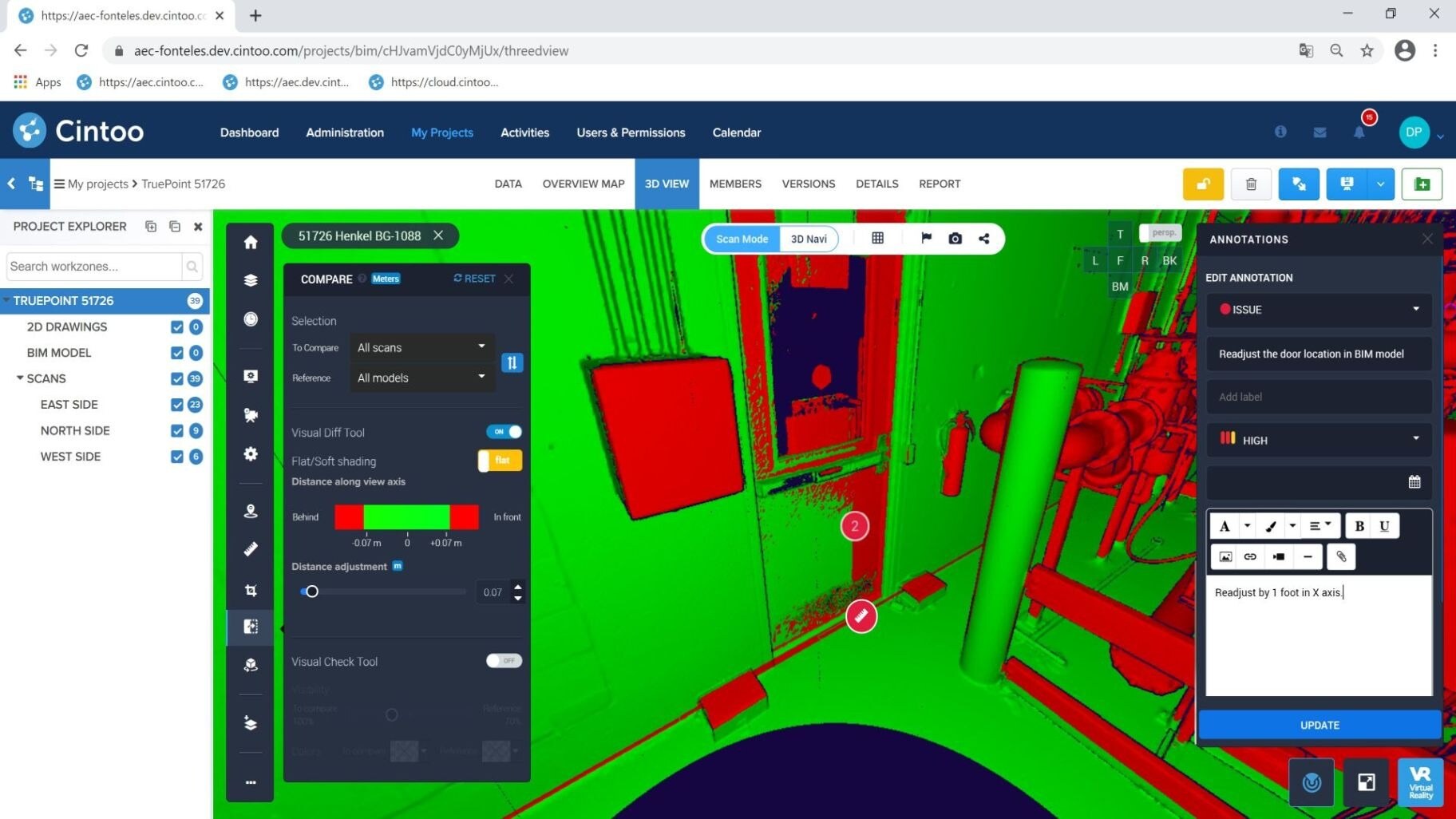

Point cloud data converted into 3D meshes gives you a virtual site model composed of all existing 3D scan data, and it can then be seamlessly integrated into BIM or CAD platforms. The ability to visualize point clouds in a 3D space significantly enhances the accuracy of the modeling process, ensuring that the digital representation aligns precisely with existing physical conditions. In Cintoo, BIM/CAD models can be brought in and overlaid against the 3D scan data, allowing a full comparison between as-built and as-designed conditions.

Integration into BIM/CAD Platforms

Another way to optimize laser scans and models is to, once processed, build models based off of 3D scan data in BIM or CAD software, such as Autodesk Revit, AutoCAD, or Bentley MicroStation. Here, the point cloud serves as a reference for creating detailed 3D models. Designers can trace over the point cloud to accurately model structural elements, including walls, floors, ceilings, and mechanical systems. This method, known as Scan-to-BIM, enables architects, engineers, and contractors to work with a digital twin of the physical environment.

This integration is particularly beneficial for renovation, remodeling, and facilities management, where understanding the existing conditions is crucial. It also enhances collaboration among project stakeholders, as the digital model provides a common reference point, reducing the likelihood of design conflicts and costly rework. Since everyone is collaborating off the same data set, it allows for a single source of visual truth. In Cintoo, further tools like annotations, asset tagging or automatic measurements means that everyone is working off the same live data and extracting real-time information.

Accurate digital twins, based on point cloud data and streamed at the highest quality in Cintoo, allows simple overlay of modelled elements.

By accurately reflecting the physical site, digital twins enable informed decision-making, efficient space utilization, and proactive maintenance planning.

Comparing Laser Scanning and Photogrammetry

Laser scanning and photogrammetry are two prominent methods for 3D reality capture, each with distinct advantages and limitations. Laser scanning is known for its exceptional accuracy and precision, often achieving millimeter-level detail. This makes it ideal for complex structures and industrial environments where high accuracy is critical. However, laser scanning requires specialized equipment, which can be costly, and the data processing is more time-consuming due to the volume and complexity of point cloud data. Despite these challenges, its precision makes it indispensable for construction validation, quality control, and complex architectural modeling.

Photogrammetry, on the other hand, uses standard digital cameras to capture overlapping images that are then processed into point clouds. It is generally more cost-effective and faster for data acquisition, especially in outdoor environments where lighting conditions are favorable. Unlike laser scanning, photogrammetry does not require expensive hardware, making it an accessible option for smaller projects or budget-constrained scenarios. However, its accuracy is typically lower than that of laser scanning and can be affected by reflective surfaces, low-light conditions, and inconsistent textures. Despite these limitations, photogrammetry is well-suited for terrain mapping, cultural heritage documentation, and scenarios where rapid data capture is needed.

Laser scanning and photogrammetry combined to form a whole picture of site conditions.

Choosing between laser scanning and photogrammetry depends on project requirements, budget constraints, and environmental factors. While laser scanning is ideal for detailed indoor environments and complex industrial sites, photogrammetry excels in outdoor terrain mapping and cultural preservation projects. In some cases, combining both methods provides a more comprehensive digital representation.

Use Cases and Scenarios

3D reality capture is transforming various industries by enhancing accuracy, efficiency, and collaboration. In architecture and construction, it is used for documenting existing structures with high precision, particularly for renovation projects where accurate measurements are critical. By utilizing point cloud data, architects can create as-built models that reflect the current state of a building, reducing the likelihood of costly errors and design conflicts. This accurate documentation streamlines renovation planning, minimizes rework, and ensures project timelines are met.

In the industrial and manufacturing sectors, 3D reality capture is used to document complex machinery layouts, plant configurations, and production workflows. Digital twins created from point clouds enable detailed space planning, safety analyses, and process optimization. By visualizing the facility in a 3D environment, manufacturers can efficiently plan equipment upgrades, improve operational efficiency, and enhance workplace safety.

For instance, GM has maximized their 3D reality capture workflows by using the Cintoo platform to collaborate across geographies, meaning different teams can have access to the same visual source of truth. In this way, GM has been able to classify assets using Cintoo’s AI classification toolkit and asset tagging, bring in models of equipment to detect any potential clashes–minimizing the need for rework or factory stalls in the process– and more quickly and efficiently transform legacy plants for new needs, like the installation of EV equipment.

Historical preservation is another significant use case, where 3D reality capture provides a non-intrusive method to record the intricate details of heritage structures. The resulting 3D models serve as valuable records for restoration efforts and virtual tourism, ensuring that cultural heritage is maintained for future generations. This digital documentation allows for accurate restoration, educational opportunities, and global accessibility to cultural sites.

Precision Point used Cintoo to complete the reconstruction of one of the oldest theatres in North America. “Cintoo gives us a streamlined, user-friendly way for our clients to view a quality and organized BIM model and point cloud seamlessly,” explained Joey Ciotti, Reality Capture Specialist at Precision Point.

The 1916 theater is a 125,000 square foot historical building that was designed and used for musical symphonies. It was in dire need of renovation and documentation. A local architectural firm was asked to do an architectural “refresh” of the brick and concrete block structure, in which the first step for Precision Point was to scan the entire site for the architectural firm. That way, they were able to upload massive point clouds into Cintoo without issues, allowing the architectural firm to design and upload models into Cintoo for an ensured accuracy of implementation.

Benefits of a 3D Reality Capture Workflow

Adopting a 3D reality capture workflow offers several benefits, including enhanced accuracy, time and cost efficiency, improved collaboration, and comprehensive documentation. Accurate point cloud measurements minimize discrepancies between the physical site and its digital representation, reducing errors and preventing costly rework. The digital models generated serve as reliable records for future renovations, maintenance planning, and legal purposes. Additionally, having accurate as-built models enhances communication among project stakeholders, leading to better decision-making and efficient project execution.

3D reality capture, through the generation of point clouds and integration into BIM and CAD models, is transforming how industries document and interact with physical spaces. Its applications across architecture, construction, manufacturing, and cultural preservation underscore its versatility and significant advantages in accuracy, efficiency, and collaboration. As technology advances, 3D reality capture will continue to play a pivotal role in digital transformation, enabling industries to innovate and optimize their workflows.

To make the most of your 3D reality capture workflows, try a demo today!