Background

Equans Digital is a division of the multi-billion-dollar company in France, Equans (a Bouygues Group company), which brings together the expertise of all the Equans divisions specializing in ICT and digital transformation with over 9,000 experts around the world. This division creates over 1.5 billion euros turnover, half of that in France.

A player in the French agri-food industry approached Equans Digital with an need to update their documentation of their facility. After many years of service, the chief Maintenance officer was retiring. During that time, many changes both in the physical aspects of the manufacturing facility as well as available technologies had changed. The only documentation available was outdated 2D drawings and the legacy knowledge that only chief Maintenance officer knew based on his many years of experience.

The situation

Unfamiliar with technology or the process of implementing a digital transformation, this customer called on Equans Digital Survey to run a pilot program to validate the initiative of using an Industry 4.0 process by scanning the plant layout, equipment and networks that would serve as the basis for 3D modelling and documenting the manufacturing facility.

Cookie Manufacturing building in France

Workflows Used

Laser scanner: Leica RTC

360 Terrestrial

Cintoo Cloud

Scan to BIM software:

Revit

software: Autodesk

Construction Cloud

Solutions

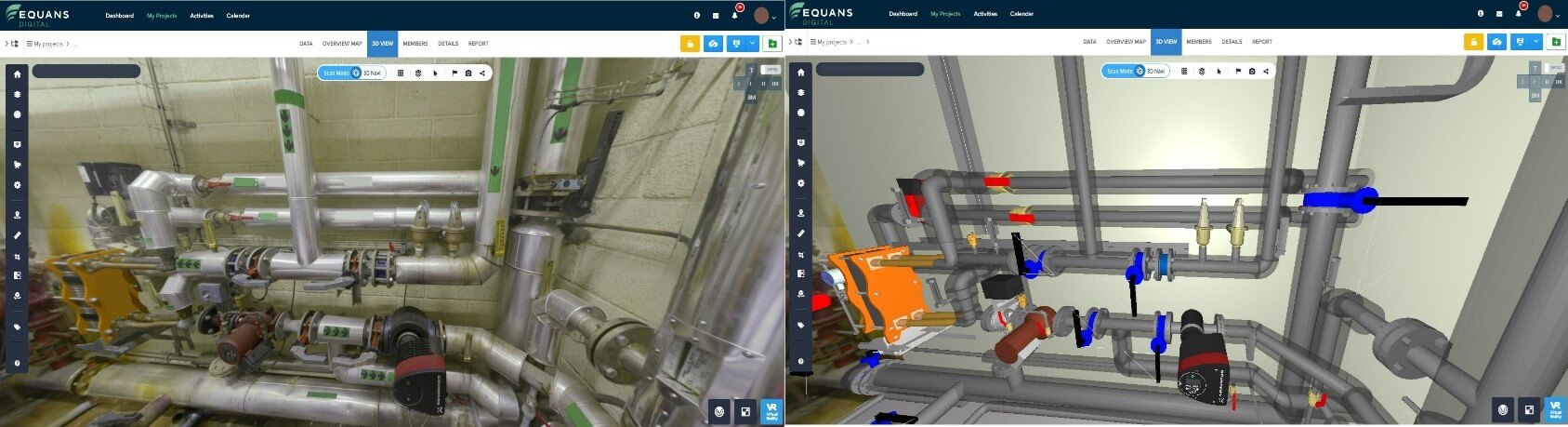

As is the case with many existing manufacturing facilities, the need to create a single source of truth using digital transformation is the key to optimizing operations in the present and for the future to assure maximizing ROI. By choosing professional experts such as Equans Digital Survey group, they can deliver successful projects using adequate tools like Cintoo. Once completed this digital blueprint will serve to not only update old 2D drawings and specifications but using Cintoo allow users to upload and compare BIM and CAD models to the actual current asset in use. In addition, the effective management of these assets for repair, optimal performance and future plant reconfigurations and construction is easily implemented using the Virtual Reality capabilities in Cintoo Cloud. Cintoo was a key platform as the final customer has no resources (neither Software or personal) that can manage Digital Solutions.

Viewing scans in Cintoo: Panoramic/Color 3D Mesh and BIM 3D Model overlaid

Since Cintoo allows for an unlimited number of users at no additional cost, as well as no charge for the size of your files, Equans Digital Survey can now share their project with all of the applicable divisions and users at Equans as well as their clients and any contractors. Once the complete facility is scanned to BIM and documented using Cintoo, the facility layouts as well as manufacturing processes and assets can be captured as they exist. By employing Cintoo Asset Tagging and Display features, future changes and updates including repairs and maintenance can be easily confirmed and documented for all applicable users anywhere at any time.