Customer Story: TruePoint

TruePoint has been providing 3D laser scanning and modeling services to the AEC industry since 2011. The company has quickly become an industry leader, providing accurate data and superior service to clients.

TruePoint empowered by Cintoo Cloud

“With Cintoo Cloud, we can take massive amounts of laser scan data and organize it for clients to utilize collaboratively.“

Aaron Hunt, Lead Technical Manager

Background

TruePoint has been providing 3D laser scanning and modeling services to the AEC industry since 2011. The company has quickly become an industry leader, providing accurate data and superior service to clients.

In an effort to optimize delivery time and leverage quality control, traditional project workflows have come under scrutiny, such as time spent uploading to file sharing services, and/or copying data to hard drives. A reduction in time allows for more robust quality control and faster delivery to its clients.

TruePoint needed a cloud-based platform to expedite the delivery of laser scan data to clients and allow them to view scans from their web browsers. TruePoint has been using Cintoo Cloud since it was developed; in fact, the team helped beta test the initial platform.

Cintoo Cloud is the best platform we have seen that allows clients to view the actual data streaming online. We can upload data, and clients are able to view it in minutes. It is an intuitive and easy-to-learn platform with tools to invite users, create team members and set access rights,” explains Aaron.

The biggest benefits for the team are:

- The ability to view scans with web browsers on mobile devices and computers (Windows, Linux, and Mac).

- Ability to share raw scan data or Autodesk Recap projects.

- Organizing a hierarchy of scans into groups known as Work Zones. This allows faster streaming of specific scans.

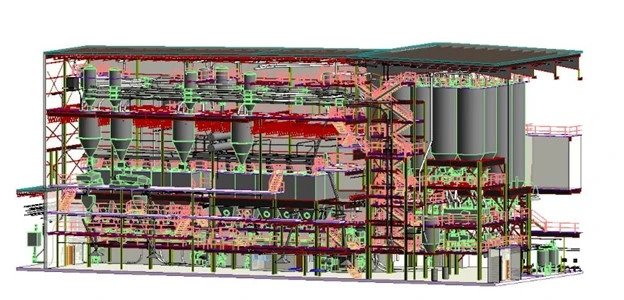

- Importing models, which can be laid over the laser scan data, and interacting with Autodesk BIM 360.

- Comparative tools to colorize differences in models and as-builts.

- Ability to collaborate with annotations and dimensions.

- Allow a change in coordinate systems and distribution to subconsultants.

Workflows Used

Leica & NavVis laser scanners

Cintoo Cloud

Autodesk Software: Revit & BIM 360

Results

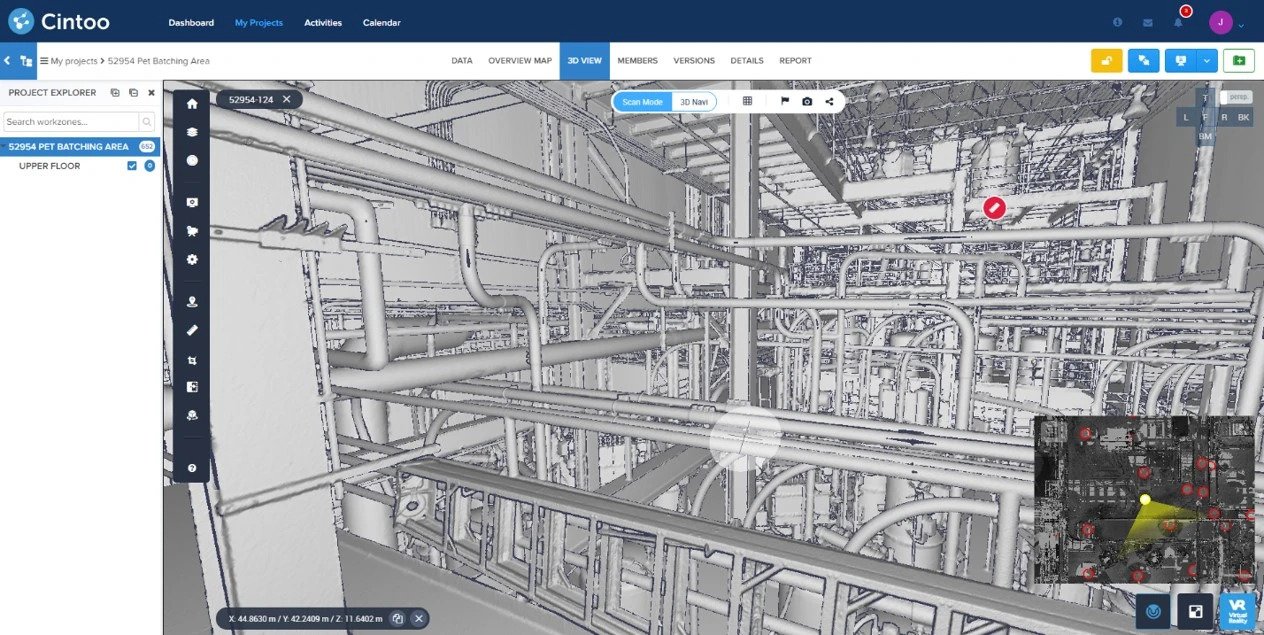

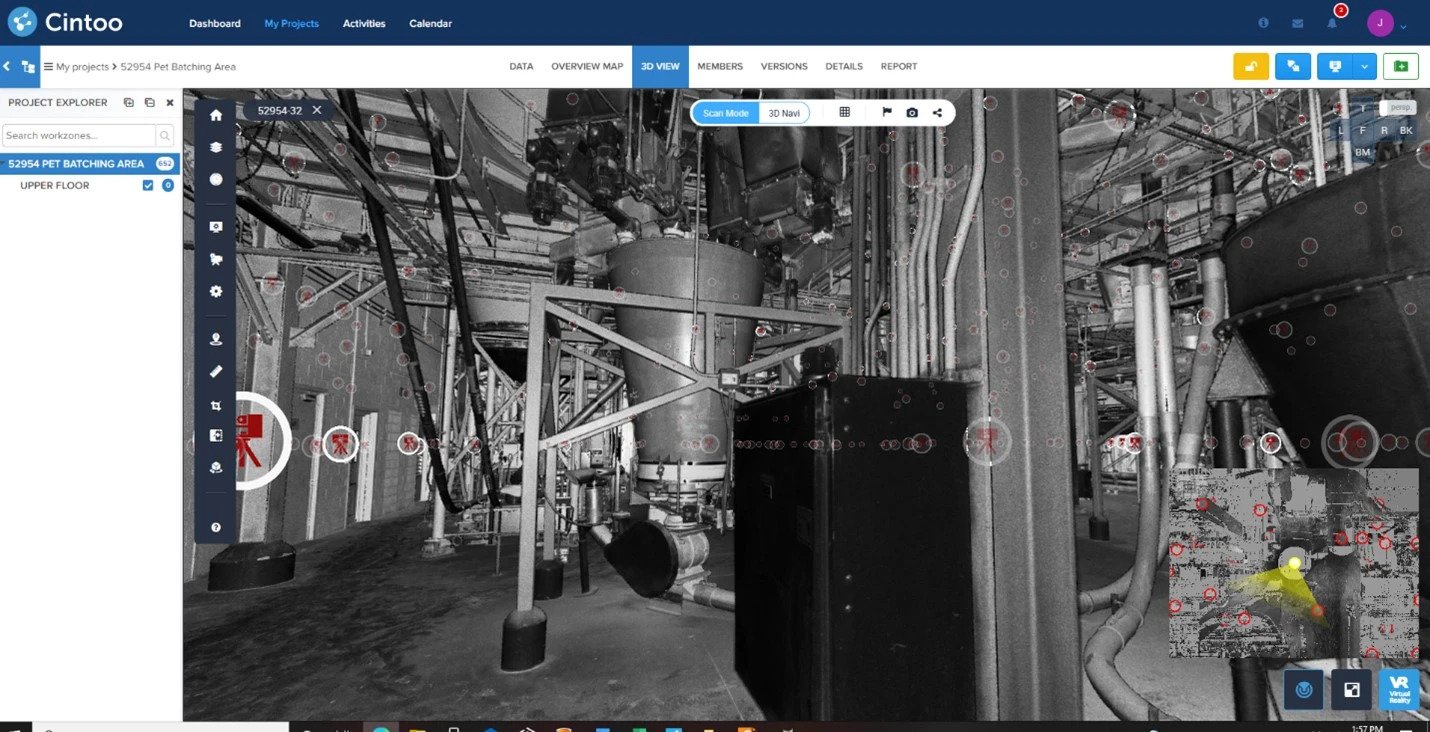

When plant engineers at a pet food packaging facility needed to make modifications, they asked TruePoint to provide as-built documentation and a 3D model to plan retrofits to the existing structure. The project site consisted of 140,000 sq. ft. of interior space, including warehouse space, packing equipment, a central palletizer, semi-truck loading bays and material storage. TruePoint documented and modeled all architectural and structural features, equipment, conduit and piping.

Project stakeholders were spread out over the United States. TruePoint uploaded the point cloud data and model to Cintoo Cloud, enabling collaboration to plan facility modifications. The plant engineers used the BIM model to begin design planning, complete virtual interference checks, estimate project costs and avoid rework.

Going forward

TruePoint continues to use Cintoo Cloud as an efficient delivery system for its projects. It aids its clients with IT restrictions and those who do not have the machines or software to view and manipulate large files. It also offers them an online workspace in which to collaborate.

Instead of relying on file sharing sites or shipping hard drives to distribute data, the team can easily upload laser scan data and models for clients. They refer to the online user guide, following the steps and screenshots for navigating and viewing the Cintoo Cloud project console, tool bar and workflows.

”We believe that in a fast-moving construction environment, team communication and resolving project issues quickly are imperative and Cintoo Cloud is a vital part of this process.”

Project and Media Links

TruePoint Laser Scanning on its website: www.truepointscanning.com