Predictive Maintenance Software for Refineries: Using Scan Data to Drive Proactive Asset Management

- Madeline Medensky

- June 13, 2025

In refinery environments—dense, high-risk, and structurally complex—the margin for error is slim. Assets operate under extreme temperatures and pressures. Facilities are labyrinthine, built across decades of upgrades, brownfield modifications, and often incomplete documentation. In this context, the traditional approach to maintenance, where teams rely on periodic inspections or failure-based interventions, even old 2D drawings, can no longer meet the scale, safety, and operational demands of modern energy markets. This is where predictive maintenance software for refineries becomes a critical enabler of safety, continuity, and performance.

Scan Data Management in Refineries

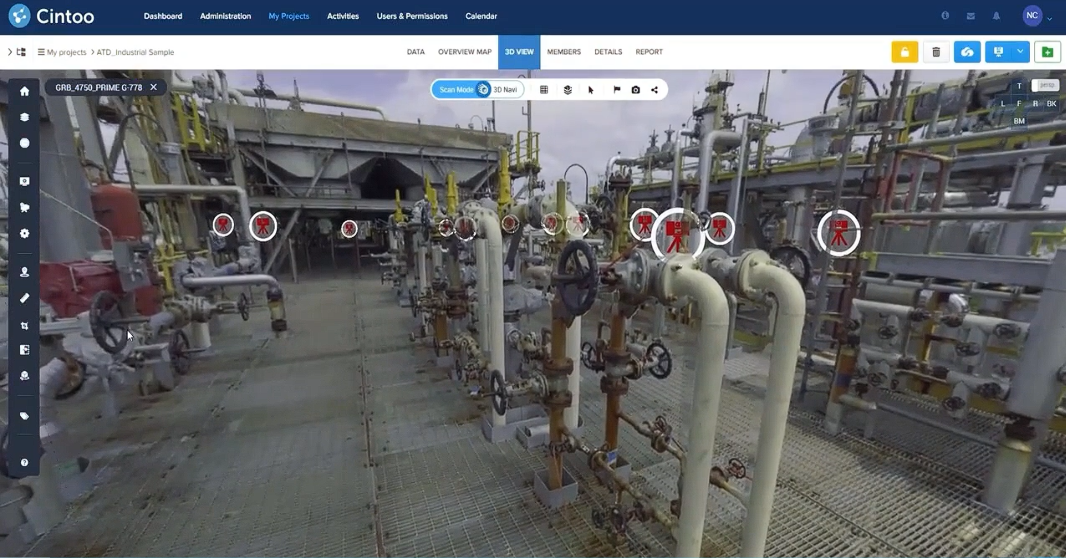

A successful predictive maintenance strategy depends on 3D scan data management. To monitor, forecast, and act on asset health, operators must first digitize and understand their physical reality with millimeter-level accuracy. Refineries are some of the most complex environments to scan. They include pipe racks layered over decades, rotating equipment in confined spaces, vertical structures, pressure vessels, flare stacks, cooling towers, and electrical rooms. Capturing and managing this complexity requires specialized lidar scanning, drone photogrammetry, and SLAM-based mobile mapping. It also requires advanced software that can not only render this data efficiently but connect it to a refinery’s wider asset management and digital twin systems.

Scan data management in refineries starts with precision reality capture. Survey-grade terrestrial scanners are deployed across process units to collect high-resolution point clouds. These scans are then aligned and registered into a unified spatial model. For refineries, this often means breaking data into logical work zones—e.g., crude distillation units, hydrocrackers, coker units, and utilities. The resulting mesh must be accurate enough to detect deformation, corrosion, alignment drift, and interstitial space availability. Once captured and processed, this data is visualized in platforms like Cintoo, where it is transformed into a navigable 3D mesh, allowing teams to access up-to-date digital representations from any location.

Why Predictive Maintenance is Critical for Refineries

The importance of predictive maintenance in refineries stems from the high cost of unplanned downtime and the risks posed by asset failure. A single day offline in a major refinery can result in losses ranging from hundreds of thousands to several million dollars, depending on output capacity and product mix. Failures in heat exchangers, compressors, or piping can trigger safety shutdowns, HSE incidents, or catastrophic damage. Predictive maintenance leverages a combination of sensor data, historical performance, and physical condition indicators—often derived from scan data—to forecast failure points before they occur. This allows teams to replace, repair, or reinforce assets at the optimal time.

Performing Predictive Maintenance Using Software

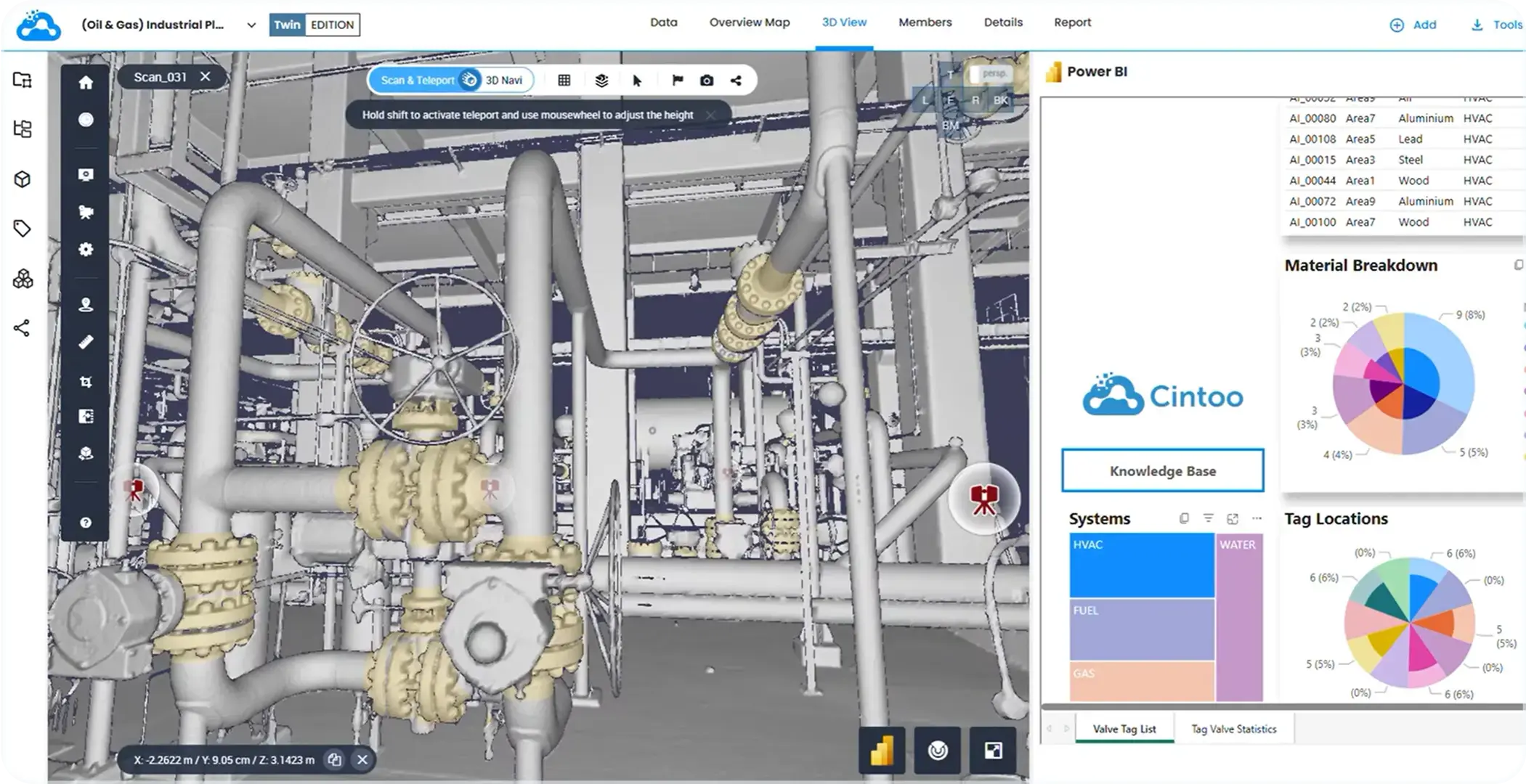

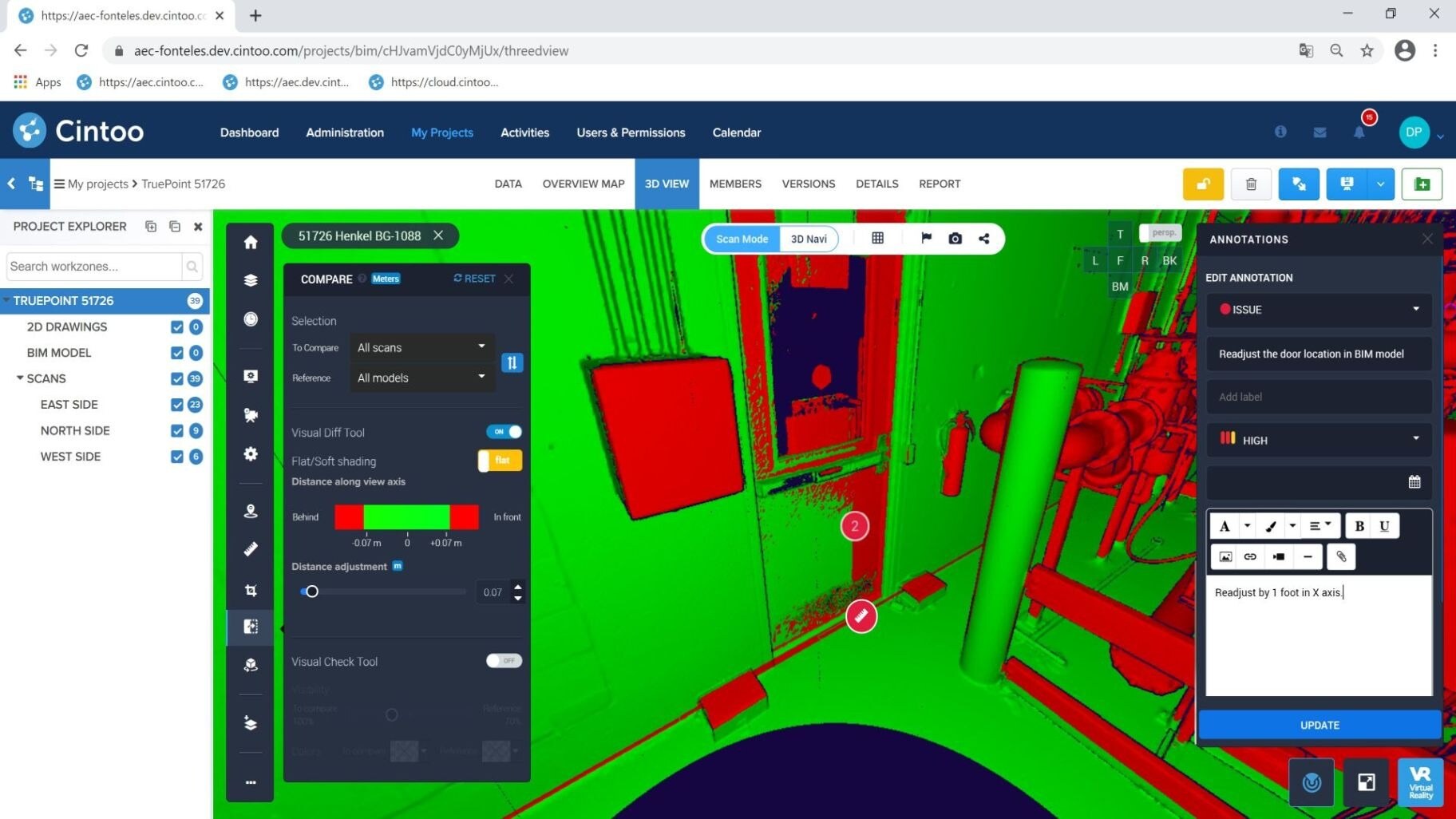

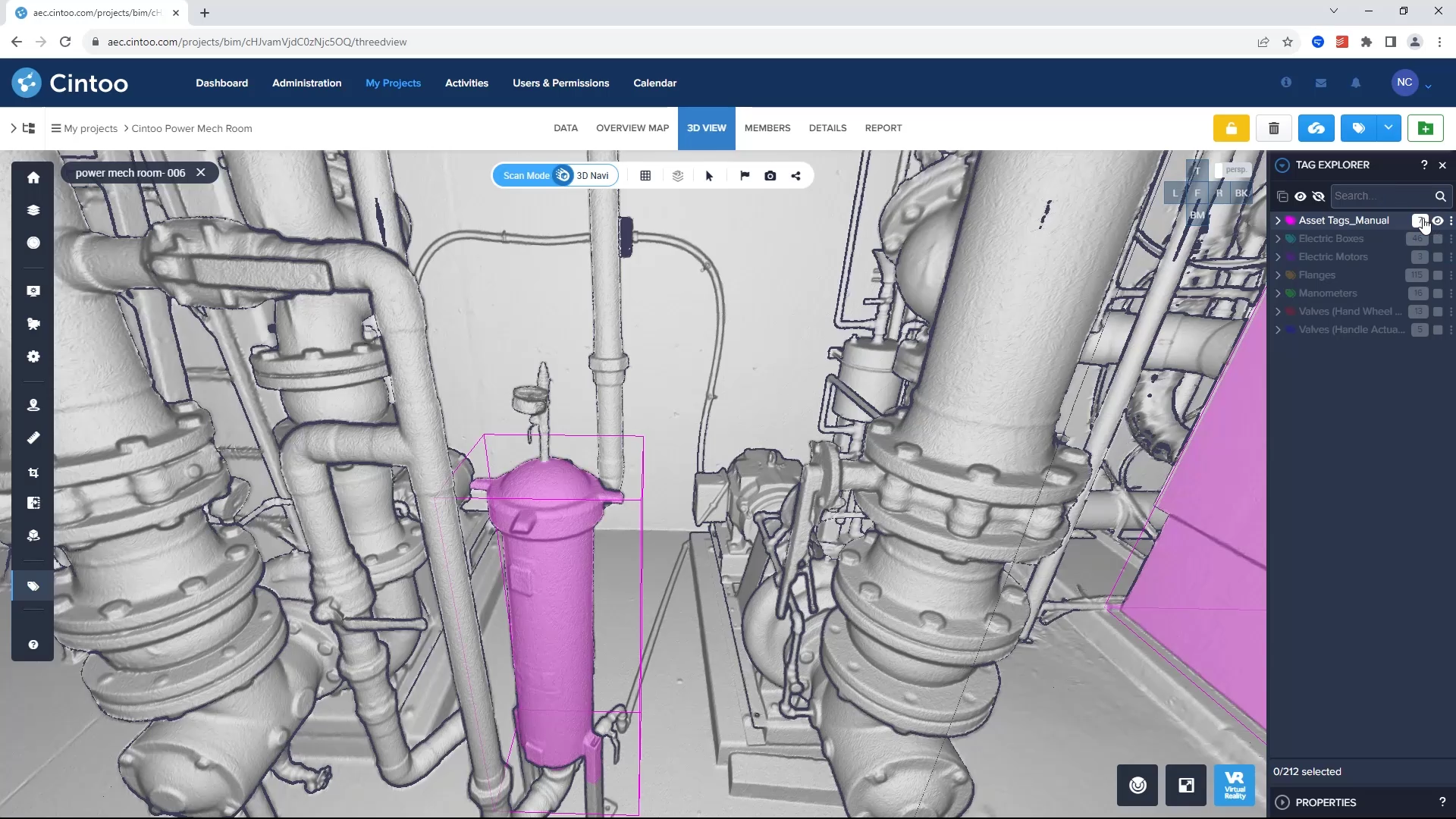

Performing predictive maintenance using Cintoo involves a combination of visual data, tagged asset metadata, historical scan comparisons, and integration with engineering models. Once a refinery’s scan data is uploaded to Cintoo, users can begin tagging individual components—such as valves, structural supports, or pumps—using precise coordinates and classification fields. These tags are enriched with metadata including installation date, inspection frequency, last maintenance action, and operational criticality. Over time, operators perform additional scans and compare them against previous data sets. This allows users to detect geometry shifts, misalignments, or surface deterioration. With Cintoo’s deviation analysis and scan-to-model comparison features, maintenance managers can quantify exactly how far an asset has deviated from its baseline condition or design specification.

In parallel, scan-based inspections can be connected to external condition monitoring systems. For example, a pump may be visually inspected via 3D scan data, while also receiving inputs from vibration sensors, temperature probes, and flow data. When this information is brought together, predictive maintenance software can prioritize which assets are most at risk, calculate remaining useful life, and recommend intervention windows. Integration with CMMS or ERP tools from Cintoo ensures that work orders and parts procurement can be scheduled well in advance—minimizing delays and maximizing uptime.

Enhancing Digital Twin Strategies with Predictive Maintenance

The value of these workflows lies in their ability to drive a more intelligent digital twin strategy. A digital twin is only as useful as the data it contains. With predictive maintenance tools layered on top of a high-resolution 3D mesh, refinery operators can transition from reactive workflows to proactive infrastructure intelligence. Teams are no longer relying on static 2D drawings or assumptions about asset condition. Instead, they are operating from a dynamic environment that reflects the true physical state of the refinery, updated in regular intervals, and enriched with asset performance insights. Over time, this creates a comprehensive digital thread that spans design, operation, inspection, and decommissioning.

Quantifying ROI from Predictive Maintenance Software

The ROI of predictive maintenance software for refineries can be quantified across several key metrics. First, there’s the reduction in unplanned downtime. By catching issues early—such as corrosion under insulation (CUI) or flange misalignment—refineries can prevent process unit shutdowns, which often cost millions per day in lost production. Second, predictive workflows extend asset lifecycles by targeting only those components that require intervention, reducing over-maintenance and waste. Third, field crew safety improves by reducing manual inspections in high-risk zones, as virtual inspections can be performed from a centralized office using scan data. Lastly, compliance and audit processes are streamlined by maintaining a digital record of inspections, deviations, and corrective actions tied to specific asset tags.

Case Study: Avoiding Unplanned Shutdowns in a Reforming Unit

A strong example of this approach in practice comes from a refinery customer using Cintoo to manage the inspection of heat exchanger structures in a reforming unit. Initial scans revealed that several support beams were sagging below design tolerances. These were tagged within the scan platform and measured against historical scan data from a turnaround performed two years earlier. Deviation analysis confirmed an accelerated deformation trend, prompting preemptive reinforcement before the next scheduled shutdown. The result was the avoidance of an unplanned stoppage, with estimated savings of over $750,000 in deferred outage costs and structural repairs. Additionally, the scan data was used to update the digital twin model for the refinery, improving engineering alignment for future modifications.

Conclusion

As refineries continue to face mounting pressure for uptime, safety, and sustainability, the role of predictive maintenance software—anchored in high-fidelity 3D scan data—will only become more central. With platforms like Cintoo, refinery operators can evolve from static inspections to dynamic digital intelligence. The result is not just better maintenance but a smarter, more resilient refinery that is always one step ahead of failure.

To learn more about how predictive maintenance and 3D scan data can modernize your refinery operations, read about digital twins in energy operations.